CONFIDENTAL. DO NOT DUPLICATE OR REDISTRIBUTE

17

Pre-Install Guide_2.0.0 | September 11, 2018

PRE-INSTALLATION GUIDE : METAL X SYSTEM

PRE-INSTALL CHECKLIST

SINTER-1

□

Installation location is environmentally controlled for temperature and humidity

□

Move furnace from crate to permanent location / table

□

Appropriate table for furnace

□

Furnace location has adequate space to meet clearance requirements

▷

Location accommodates space to install tube

▷

Location accommodates space to install gas lines

□

Furnace location can support the fully loaded weight of the furnace

□

Furnace location is level

□

Compatible Wi-Fi or Ethernet network connection

□

Dedicated circuit for furnace (see

Facilities Guide

for specifications)

▷

Furnace permanently wired into circuit

□

4” or 6” round exhaust hookup at furnace loc`ation

▷ Measure exhaust and confirm it is at least 100CFM. Record CFM: ________

□

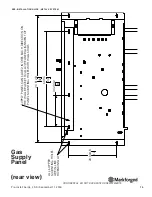

Gas supply panel installed

□

Gas cylinder mounting rack installed

□

Gas cylinders on site

▷ (2) 300cf of mix gas (97.1% Ar, 2.9% H2, UHP [99.999%])

▷ (1) 300cf of backup inert gas (100% Ar, UHP [99.999%])

▷ (1) 230L medium/high pressure cryogenic liquid container of inert gas (100% Ar,

UHP [99.999%]