Combimatic_v2_EN_210315 35

Combimatic

Maintenance and Service

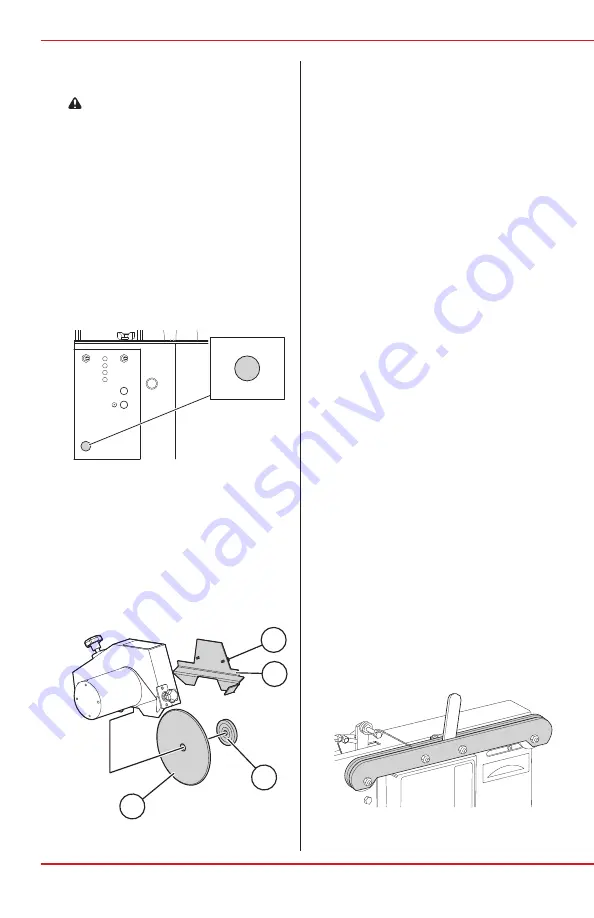

6 .3 Change the grinding wheel and

fit the grinding wheel guard

WARNING Before a chain is sharpened, make

sure that the grinding wheel is not cracked, does not

vibrate or wobble . There is a simple test (called the

“ring test”) that you can do to check for damage (see

section 4 .7, “Install and center the grinding wheel”) .

IF THE GRINDING WHEEL IS DAMAGED IT MUST

BE REPLACED IMMEDIATELY .

If abnormal vibrations occur during operation, stop

the machine immediately and check the condition of

the grinding wheel .

The machine comes with 2 grinding wheels of

different sizes . To order more grinding wheels, see

8, “Accessories and Spare Parts” .

1 . Press the stop button to turn the power off .

2 . Lift the grinding head to its most upright

position .

3 . If the grinding wheel guard is already attached:

Loosen the 2 attachment knobs (D) and remove

the guard (C) .

4 . Hold the grinding wheel and loosen the nut

(B) .

C

D

B

A

5 . Remove the grinding wheel (A) from

the grinding wheel axis and discard it in

accordance with local, state and national laws

and regulations .

6 . Place a new grinding wheel (A) on the grinding

wheel axis .

7 . Tighten the nut (B) by hand to secure the

grinding wheel in its position . Do not over-

tighten the nut .

8 . Place the grinding wheel guard (C) in its

position and fasten the 2 knobs (D) .

9 . Center the grinding wheel following the

instructions in 5 .2 .9, “Center the grinding disc” .

6 .4 Set the depth gauge height

1 . Do a sharpening test on a test chain, according

to the instructions in section 7 .2, “Sharpening

2 . Verify the correct depth gauge setting (refer to

the illustration) .

3 . Turn the grinding depth knob to set the depth

gauge: See section 3 .2, “Front view” position

(H) .

• clockwise to increase the height of the depth

gauge (and therefore grind less of it), or

• counter clockwise to decrease the height of

the depth gauge (and therefore grind more

of it) .

4 . Repeat the sharpening test until the height of

the depth gauges is correct .

6 .5 Fasten the chain lock

The chain lock needs to be fastened if the chain is

not fixed during sharpening .

1 . Insert a 1,8–2,0 feeler gauge into the groove of

the chain lock to measure the groove width .

1.8-2.0 mm