Rutland 504 Windcharger Installation & Operation

Doc No: SM-150 Issue C 17.03.14 17 Marlec Eng Co Ltd

4. Running Tests:

x

Check for power output from the windcharger following this procedure:

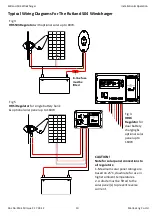

A Set a digital multi-meter to DC Amps, scale of up to 5A or less if possible. Connect the

meter positive (+) probe to the wind gen output positive cable and the meter negative (-) to

the regulator input positive. Provided there is sufficient wind there should be a current

reading. This establishes that power is being delivered.

B Using the same multi-meter setting as above measure between the “regulator to battery” +

and the b. Provided there is sufficient wind there should be a current reading. This

establishes if power is passing through the regulator.

C If both above are unsuccessful set the multi-meter to DC Volts. Disconnect the wind

generator from the regulator and connect the meter + to the wind gen + and the meter – to

the wind gen -. Provided there is sufficient wind there should be a variable voltage reading

according to the speed of the wind seen at the wind turbine. This will establish if the wind

generator is able to deliver power or not.

D If tests A and C are successful but test B fails to produce results connect the wind gen

directly to the battery. Set the digital multi-meter to DC Amps and measure power

between the wind gen + and the b. If a reading is measured, providing there is

sufficient wind, then the regulator is faulty.

E If the wind turbine fails to deliver any current or open circuit V reading undertake the further

tests below.

5. Mechanical inspection. It may be necessary to remove the Wind charger from its pole for

the following tests.

A Check the brushes and slip ring for wear or damage.

x

To inspect the brushes, remove the tail fin and the plastic nacelle.

x

The brushes can be inspected by removing the caps from the brush holders & withdrawing

the brushes.

x

Heavy deposits on the slipping and reduced power indicate a possible reverse connection

to the battery. Clean the slipping with fine glass paper and fit new brushes.

B Check hub for free rotation with generator disconnected from battery.

x

If the hub does not rotate freely, check for a possible short circuit in the wiring.

x

If no wiring fault is found refer to your dealer or manufacturer.

If the above checks have identified a need for spare parts or failed to identify the problem you

should contact Marlec who can advise you of your nearest distributor in their world wide

network. In the first instance we recommend that you contact the company from whom the

product was originally purchased.

If in doubt, refer to your dealer or manufacturer.

Summary of Contents for Rutland 504 efurl

Page 2: ......