10. Install optional controls (if required) into the heater section

in accordance with the Instruction Sheet packaged with the

control.

11. To wire the heater, thermostat, reduce wattage or convert

from single to three-phase voltage, refer to “Field

Conversion for Lower Wattage Rating” or “Conversion for

3ø Installation” on page 7 and wiring diagrams, Figure 13,

page 7.

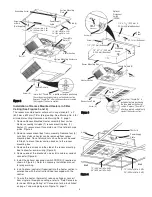

12. Position the heater section over the studs in the recess

mounting box (Figure 8).

Note:

The end of the heater section with the terminal block must

be posi tioned at the end of the recess mounting box where the

supply wiring enters.

13. Push the heater section onto the studs and securely tighten

the four (4) nuts (removed from step 4) on the studs to

secure the heater section to the recess mounting box

(Figure 8).

14. Connect the ground wire to the green ground screw on the

recess mounting box.

15. Position the recess face plate over the heater

section/recess mounting box, making sure that the thumb

pins are in the holes in the heater section.

16. With the recess face plate seated firmly against the heater

section, depress the “thumb pins”. This will cause the

thumb pins to expand and will temporarily hold the recess

face plate in place.

Note:

The thumb pins are an aid to help position and hold the

recess face plate during installation. Additional support (Step 17)

is required. See Warning, page 2.

17. Install and securely tighten four screws (supplied) to secure

the recess face plate to the heater section (Figure 8).

18. Install discharge air grilles. (Refer to “Installation of

Discharge Air Grilles.”)

Installation of Discharge Air Grilles

(See Figures 9, 10 and 11)

1. Refer to “Adjustable Discharge Grilles Custom Air Flow

Patterns”, page 6 of this instruction sheet to determine

desired air flow direction.

2. Place the two discharge grilles onto a flat surface in the

desired configura tion with tabs on each end of grilles

upward.

3. Fit the two louver guides over the two discharge grilles as

shown in Figure 9.

4. While holding the assembly together with both hands, fit one

side of assembly into the opening of the enclosure, and slide

this side inward while fitting the opposite side into the enclo-

sure. (See Figure 10.) Slide the assembly into position so

that the bottom portion of each guide locks into the opening.

FAILURE TO INSTALL THE FOUR MOUNTING NUTS COULD

RESULT IN THE HEATER FALLING (SEE FIGURE 8).

TO REDUCE THE RISK OF FIRE OR PERMANENT DAMAGE

TO THE HEATER, THERMOSTAT MUST BE WIRED AS

SHOWN IN WIRING DIAGRAM. DO NOT CONNECT THER-

MOSTAT IN MAIN POWER LINES BECAUSE IT WILL

DEFEAT THE FAN DELAY FUNCTION.

THE HEATER ENCLOSURE MUST BE SECURELY MOUNT-

ED TO CEILING OR FRAMING CAPABLE OF SUPPORTING

THE HEATER (45 LBS/20.4 KG). FAILURE TO DO SO COULD

ALLOW HEATER TO FALL.

5

1/2” (12.2 mm) Knockout

7/8” & 1

1

/8”

(22.2 & 28.5 mm)

Nested Knockout

1/2” (12.2 mm)

Knockout

Cable or

Conduit

Connector

7/8” & 1

1

/

8

”

(22.2 & 28.5 mm)

Nested Knockout

Recess

Mounting

Box

Optional

Disconnect

Switch (CDFDS)

Screw (2)

Recess

Mounting

Box

F

Fiig

gu

urre

e 7

7

Grounding

Screw

Power Supply

Cable

Stud (4)

Nut (4)

Thumb

Pin Hole

Heater

Section

Screw (4)

Recess Face

Plate

Insure that “Thumb Pin” is pulled out

before positioning the face plate on

the heater section. Depress “Thumb

Pin” after face plate is sealed firmly

against the heater section.

F

Fiig

gu

urre

e 8

8

Thumb Pin