19

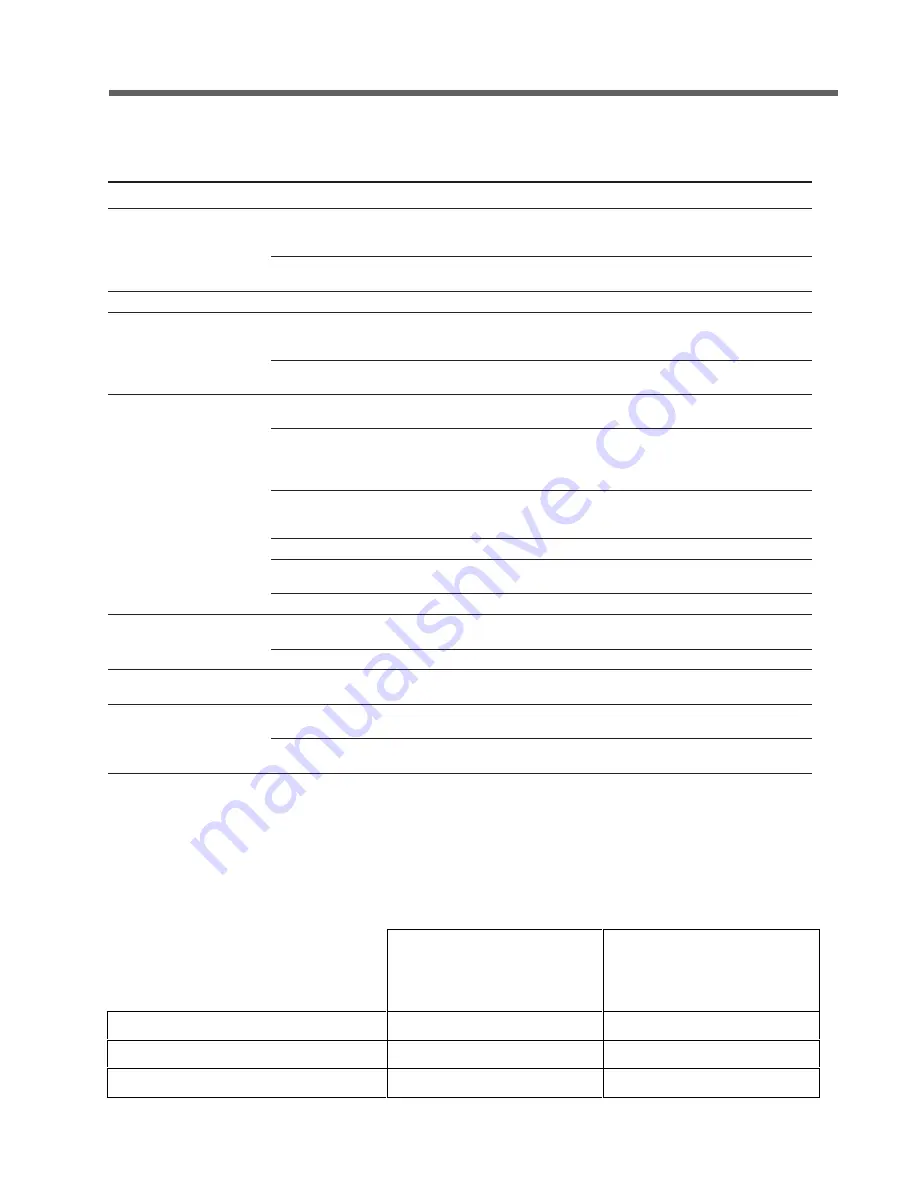

Ladders, Stairways,

Walkways, Handrails, Covers,

Decks and

Access Doors

Davits, Derricks, and Hoists

Inspect for General Condition

Semi-annually

Semi-annually

Inspect and Repair for Safe Use

Yearly

Inspect and Repair Before Each Use

As Required

SAFETY

–The F400 Clearsky cooling tower has been designed to provide a safe working environment while either

operating or shut down. The ultimate responsibility for safety rests with the operator and owner. When water flow to

the tower is shut off or when portions of the tower require maintenance, temporary safety barricades may be required

around openings and fall protection equipment should be utilized where appropriate for compliance with OSHA regula-

tions, standards and good safety practices.

Routine periodic maintenance must be

performed on all personnel access and

material handling accessories in accordance

with the following schedule:

troubleshooting

Trouble

Cause

Remedy

Motor does not come up to

speed

Voltage too low at motor

terminals because of line drop

Check transformer and setting of taps. Use higher voltage on

transformer terminals or reduce loads. Increase wire size or reduce

inertia.

Broken rotor bars

Look for cracks near the rings. A new rotor may be required. Have

motor service person check motor.

Wrong motor rotation

Wrong sequence of phases

Switch any two of the three motor leads.

Geareducer noise

Geareducer bearings

If new, see if noise disappears after one week of operation. Drain, flush

and refill Geareducer oil. See Geareducer User Manual. If still noisy,

replace.

Gears

Correct tooth engagement. Replace badly worn gears. Replace gears

with broken or damaged teeth

Unusual fan drive vibration

Loose bolts and cap screws

Tighten all bolts and cap screws on all mechanical equipment and

supports.

Unbalanced driveshaft or worn

couplings

Make sure motor and Geareducer shafts are in proper alignment and

“match marks” properly matched. Repair or replace worn couplings.

Rebalance driveshaft by adding of removing weights from balancing

cap screws. See Driveshaft User Manual.

Fan

Make certain all blades are as far from center of fan as safety devices

permit. All blades must be pitched the same. See Fan User Manual.

Clean off deposit build-up on blades

Worn Geareducer bearings

Check fan and pinion shaft endplay. Replace bearings as necessary.

Unbalanced motor

Disconnect load and operate motor. If motor still vibrates, rebalance

motor.

Bent Geareducer shaft

Check fan and pinion shaft with dial indicator. Replace if necessary.

Fan noise

Blade rubbing inside of fan

cylinder

Adjust cylinder to provide blade tip clearance.

Loose bolts in blade clamps

Check and tighten if necessary.

Insufficient Cold Water

Tower operating in plume

abatement mode

See ClearSky Operation Logic diagram on page 10.

Plume

Insufficient dry air

Close vent doors and incrementally open dry dampers. See ClearSky

Operation Logic diagram on page 10.

Duty more difficult than design

Tower will plume. Configure for maximum plume mode. See ClearSky

Operation Logic diagram on page 10.