Installation Manual -

DVC/DVH 09/12/18/24 Series

17

Page 18

6. Feed the signal wire through this slot, from

the back of the unit to the front.

7. Facing the front of the unit, match the wire

colors with the labels on the terminal block,

connect the u-lug and and firmly screw each

wire to its corresp onding terminal.

CAUTION

DO NOT MIX UP LIVE AND

NEUTRAL

WIRES

This is dangerous, and can cause the air

conditioning unit to malfunction.

8.

After checking to make sure every connection

is secure, use the cable clamp to fasten the

signal cable to the unit. Screw the cable clamp

down tightly.

9.

Replace the wire cover on the front of the

unit, and the plastic panel on the back.

NOTE ABOUT WIRING

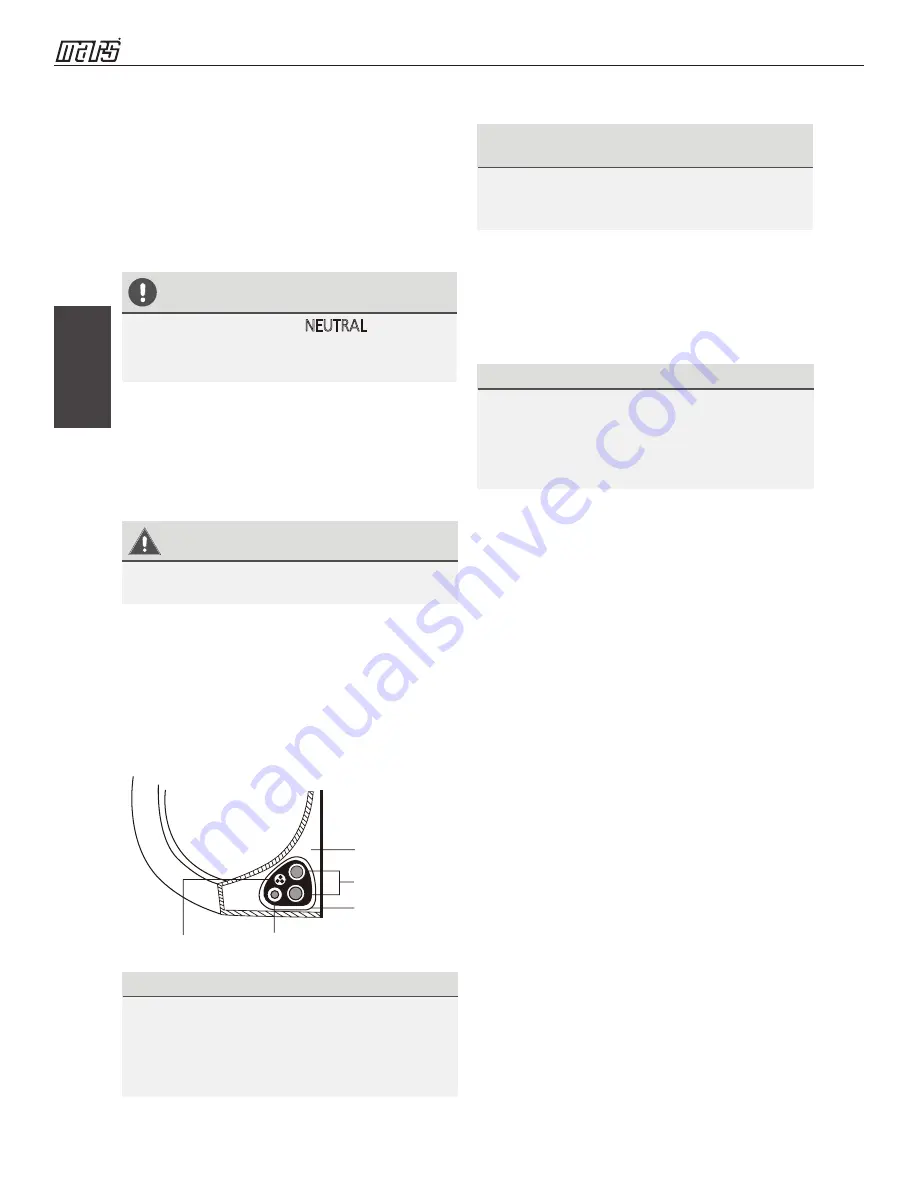

Step 7: Wrap piping and cables

Before passing the piping, drain hose, and the

signal cable through the wall hole, you must

bundle them together to save space, protect

them, and insulate them.

1.

Bundle the drain hose, refrigerant pipes, and

signal cable according to

Fig. 3.10.

Indoor Unit

Space behind unit

Refrigerant piping

Drain hose

Signal wire

Insulation tape

DRAIN HOSE MUST BE ON BOTTOM

Make sure that the drain hose is at the bottom

of the bundle. Putting the drain hose at the

top of the bundle can cause the drain pan

to overflow, which can lead to fire or water

damage.

DO NOT INTERTWINE SIGNAL CABLE WITH

OTHER WIRES

While bundling these items together, do not

intertwine or cross the signal cable with any

other wiring.

2. Using adhesive vinyl tape, attach the drain

hose to the underside of the refrigerant pipes.

3.

Using insulation tape, wrap the signal wire,

refrigerant pipes, and drain hose tightly

together. Double-check that all items are

bundled in accordance with

Fig. 3.10.

DO NOT WRAP ENDS OF PIPING

When wrapping the bundle, keep the ends

of the piping unwrapped. You need to access

them to test for leaks at the end of the

installation process (refer to

Electrical Checks

and Leak Checks

section of this manual).

Step 8: Mount indoor unit

If you installed new connective piping to the

outdoor unit,

do the following:

1.

If you have already passed the refrigerant

piping through the hole in the wall, proceed

to Step 4.

2. Otherwise, double-check that the ends of the

refrigerant pipes are sealed to prevent dirt or

foreign materials from entering the pipes.

3. Slowly pass the wrapped bundle of refrigerant

pipes, drain hose, and signal wire through the

hole in the wall.

4. Hook the top of the indoor unit on the upper

hook of the mounting plate.

5. Check that unit is hooked firmly on mounting

by applying slight pressure to the left and

right-hand sides of the unit. The unit should

not jiggle or shift.

6.

Using even pressure, push down on the

bottom half of the unit. Keep pushing down

until the unit snaps onto the hooks along the

bottom of the mounting plate.

7. Again, check that the unit is firmly mounted

by applying slight pressure to the left and the

right-hand sides of the unit.

Fig. 3.10

Indoor Unit

Installation

THE WIRING CONNECTION PROCESS MAY

DIFFER SLIGHTLY BETWEEN UNITS.