OWNER’S MANUAL

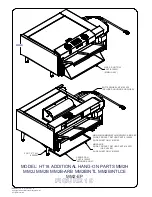

MODEL HT18 AUTOTOAST™ HORIZONTAL TOASTER

144328 RV082813

7

Copyright

2013 Marshall Air Systems, Inc.

All Rights Reserved.

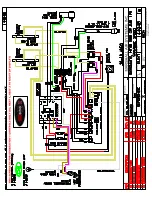

F. Control Generation 2 – Check for 24 Vdc from control board to motor relay (R3). If relay is

getting 24 Vdc, check for 208 volts on output side of relay. If no 208 volts, replace relay.

6. PROBLEM: Product is over or under toasted.

SOLUTION:

OPERATOR CHECK:

A. Check the gap settings. There must be compression of the bun as it feeds into the toaster.

Decreasing the gap will increase bun temperature and darken surface color. To lower (decrease

gap) turn knob counter-clockwise; to raise (increase gap) turn knob clockwise.

B. Check toast time. Time should be 20 seconds nominal from start to finish.

C. Check conditions of toaster platen sheet and belts. Clean both as noted in this manual.

D. Make sure conveyor belts are not binding.

E. Check drive system for loose sprockets.

QUALIFIED SERVICE TECHNICIAN CHECK:

A. Check that heaters are cycling. Do this by using an amp clamp on either of the wires from the

controller to the platen. You are looking for cycling. Also verify that the temperature controller

has power.

B. Check that the 3 wires from the speed board are hooked to the speed control.

7. PROBLEM: Buns do not feed properly into toaster.

SOLUTION:

OPERATOR CHECK:

A. Check condition of the toaster platen sheet to be sure buns are not sticking. Clean sheet as

described in daily maintenance. Replace if needed. Sheet should be rotated daily.

B. Check toaster platen sheet installation.

C. Toaster gap set too close or too far. See instructions on Page 1, Number 12.

8. PROBLEM: Buns do not exit toaster.

SOLUTION:

OPERATOR CHECK:

A. Check condition of the toaster platen sheet to be sure buns are not sticking. Clean sheet as

described in daily maintenance. Replace if needed. Sheet should be rotated daily.

B. Check toaster platen sheet installation.

C. Toaster platen gap set too close.

QUALIFIED SERVICE TECHNICIAN CHECK:

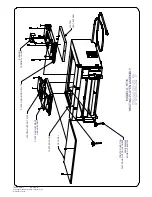

A. Check tension on lower conveyor. If too loose, buns will not exit. Tighten conveyor by adjusting

the Plate Tension Assembly (See Figure 5).