OWNER’S MANUAL

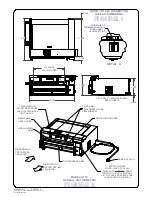

MODEL HT18 AUTOTOAST™ HORIZONTAL TOASTER

144328 RV121814

2

Copyright

2013 Marshall Air Systems, Inc.

All Rights Reserved.

toaster belt is 8 – 70 seconds; the MM2B and MM2G series is 9 – 105 seconds.

14.

Test at least 3 buns before putting the toaster into service. Uniform surface toasting and bun temperature

are achieved when the gap described in step 12 is set correctly.

15.

If necessary, the speed of the conveyor can be changed. The speed control is located behind a box on the

front of the unit. (See Figure 2) which can be removed using a 5/32 Allen wrench through the hole in the

front. Adjust as needed and reinstall box.

OPERATION (OPTIONAL PUSH BUTTON MM2A SERIES)

1. The toaster is operated by pressing and releasing the button on the right side of the unit.

2. Allow the toaster to heat up for at least 15 minutes prior to use.

3. For proper operation, insert heels cut side up on the side of the toaster marked "HEEL", and crowns on

the opposite side.

4. To turn off, press and hold the button on right side of toaster for three (3) seconds. The toaster will cool

enough to remove parts after at least 30 minutes.

OPERATION (OPTIONAL 3 DIGIT CONTROL)

1. The toaster is operated by pressing and releasing the “I/O” Button of the control. “Lo” will be displayed.

2. The display of the control will show “Rdy” once the toaster is up to temperature. (Approximately 15

minutes.)

3. For proper operation, insert heels cut side up on the side of the toaster marked "HEEL", and crowns on

the opposite side.

4. To turn off, press and hold the “I/O” Button for three (3) seconds. “Hi” will be displayed which means unit

is still too hot to remove any parts. Once the toaster has cooled (approximately 30 minutes), the display

will show “Off.”

5. The LED Control will indicate important information:

A. Press and release either the Heat 1(Crown) or the Heat 2 (Booster) Button, the pre-programmed

temperature settings will flash. This will display for 5 seconds or until another button is pressed.

B. Press and hold either the Heat 1(Crown) or the Heat 2 (Booster) Button for 3 seconds, the actual

platen temperatures will be displayed. This will display until another button is pressed.

6.

Definitions of various displays:

“Off”

Unit is off and not operating.

“Lo”

Heater platens have not reached programmed set temperature.

“Rdy”

Unit has reached programmed set temperature and is ready to toast.

“Hi”

Unit is off and too hot to touch most removable parts.

“AL1”

This is an alarm message that indicates the Left Platen Probe is disconnected or

defective. Contact your local qualified service agency.

“AL2”

This is an alarm message that indicates the Right Platen Probe is disconnected or

defective. Contact your local qualified service agency.

“AL3”

This is an alarm message that indicates the Left Platen is too hot. Unit shuts off.

Contact your local qualified service agency.