3

200-2523

CAUTION

SAFETY GUIDELINES

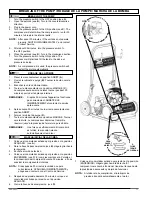

The following information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this

information, we use the following symbols. Please read the manual and pay attention to these sections.

– A POTENTIAL HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE.

– A POTENTIAL HAZARD THAT COULD CAUSE SERIOUS INJURY OR LOSS OF LIFE.

– A POTENTIAL HAZARD THAT MAY CAUSE MODERATE INJURY OR DAMAGE TO EQUIPMENT.

WARNING:

DANGER:

CAUTION:

1.

RISK OF FIRE OR EXPLOSION.

Never spray

flammable liquids in a confined area. It is normal for

the motor and pressure switch to produce sparks

while operating. If sparks come into contact with

vapors from gasoline or other solvents, they may

ignite, causing fire or explosion. Always operate the

compressor in a well–ventilated area. Do not smoke

while spraying. Do not spray where sparks or flame

are present. Keep compressor as far from spray area

as possible.

2.

RISK OF BURSTING.

Do not weld, drill or modify the

air tank of this compressor. Welding or modifications

on the air compressor tank can severely impair tank

strength and cause an extremely hazardous

condition. Welding or modifying the tank in any

manner will void the warranty.

3.

RISK OF ELECTRICAL SHOCK.

Never use an

electric air compressor outdoors when it is raining or

on a wet surface, as it may cause an electric shock.

4.

RISK OF INJURY.

This unit starts automatically.

ALWAYS shut off the compressor, remove the plug

from the outlet, and bleed all pressure from the

system before servicing the compressor, and when

the compressor is not in use. Do not use the unit with

the shrouds or beltguard removed. Serious injury

could occur from contact with moving parts.

5.

RISK OF BURSTING.

Check the manufacturer’s

maximum pressure rating for air tools and

accessories. Compressor outlet pressure must be

regulated so as to never exceed the maximum

pressure rating of the tool. Relieve all pressure

through the hose before attaching or removing

accessories.

6.

RISK OF BURNS.

High temperatures are generated

by the pump and manifold. To prevent burns or other

injuries, DO NOT touch the pump, manifold or

transfer tube while the pump is running. Allow them to

cool before handling or servicing. Keep children away

from the compressor at all times.

7.

RISK TO BREATHING.

Be certain to read all labels

when you are spraying paints or toxic materials, and

follow the safety instructions. Use a respirator mask if

there is a chance of inhaling anything you are

spraying. Read all instructions and be sure that your

respirator mask will protect you. Never directly inhale

the compressed air produced by a compressor. It is

not suitable for breathing purposes.

8.

RISK OF EYE INJURY.

Always wear ANSI Z87.1

approved safety goggles when using an air

compressor. Never point any nozzle or sprayer

toward a person or any part of the body. Equipment

can cause serious injury if the spray penetrates the

skin.

9.

RISK OF BURSTING.

Do not adjust the relief valve

for any reason. Doing so voids all warranties. The

relief valve has been pre-set at the factory for the

maximum pressure of this unit. Personal injury and /or

property damage may result if the relief valve is

tampered with.

10.

RISK OF BURSTING.

Do not use plastic or pvc pipe

for compressed air. Use only gavanized steel pipe

and fittings for compressed air distribution lines.

11.

RISK TO HEARING.

Always wear hearing protection

when using an air compressor. Failure to do so may

result in hearing loss.

12. The power cord on this product contains lead, a

chemical known to the State of California to cause

cancer, and birth defects or other reproductive harm.

Wash hands after handling.

NOTE: ELECTRICAL WIRING.

Refer to the air compressor’s

serial label for the unit’s voltage and amperage

requirements. Ensure that all wiring is done by a

licensed electrician, in accordance with the National

Electrical code.

WARNING

1.

Drain the moisture from the tank on a daily basis. A

clean, dry tank will help prevent corrosion.

2.

Pull the pressure relief valve ring daily to ensure that

the valve is functioning properly, and to clear the

valve of any possible obstructions.

3.

To provide proper ventilation for cooling, the

compressor must be kept a minimum of 12 inches (31

cm) from the nearest wall, in a well–ventilated area.

4.

To prevent damage to tank and compressor on

stationary models, the tank must be shimmed so the

pump base is level within 1/8” to distribute oil

properly. All feet must be supported, shimming where

necessary, prior to attaching to the floor. Fasten all

feet to floor. We also recommend the use of vibration

pads (094-0021) under tank feet.

5.

Fasten the compressor down securely if transporting

is necessary. Pressure must be released from the

tank before transporting.

6.

Protect the air hose and electric cord from damage

and puncture. Inspect them weekly for weak or worn

spots, and replace if necessary.

7.

To reduce the risk of electric shock, do not expose to

rain. Store indoors.

8.

Never operate the compressor if the power cord or

plug are damaged. Take the equipment to the nearest

Authorized Service Center , and a specialist technician

will replace it.

Summary of Contents for DUOFLEX HC125A

Page 25: ...25 200 2523 NOTES REMARQUES NOTAS...

Page 32: ......