11 of 36

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.MARSHALLTOWN.com

WS1987

PRE-OPERATIONAL CHECKS

CONTROLS AND ACCESSORIES

The following steps should be taken prior to using the power trowel:

1. The operator must be familiar with the location and operation of all controls.

2. The unit ships with oil, but check the crankcase oil and fill the fuel tank before starting. Read and

understand the engine manual supplied with this machine regarding adjustments, operation, and

maintenance before operating this machine.

3. Check the gearbox oil sight glass to ensure the oil is filled halfway up the glass. Use only

MARSHALLTOWN gearbox oil to fill and do not over fill.

4. Check the fuel filter and inspect air filter

5. Check both safety switches and electrical connections.

6. Check nuts and bolts to ensure nothing has loosened during shipping.

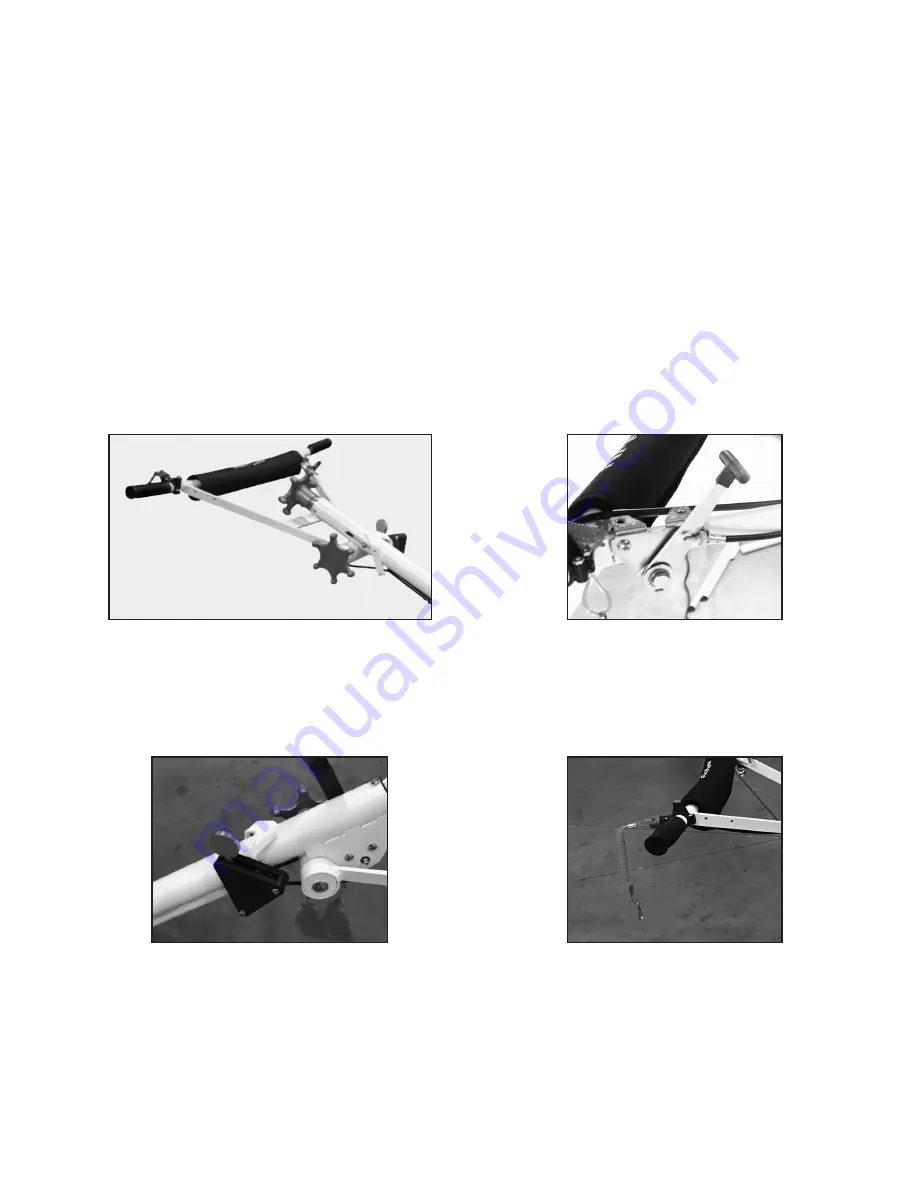

Handles

The handle bar is adjusted by simply unscrewing the

adjustment knob attached to the handle and moving

the handle to the preferred height (Figure 12)

Centrifugal Safety Switch

The weight within the safety switch must be able

to move freely without obstruction forward and

backwards. Test the safety switch before every use.

Failure to have a free moving or properly functioning

switch will inhibit the switch from working as intended.

Push the weight away from you so that it is closer to

the engine before starting the trowel.

Throttle

Throttle should be in the furthest forward position

before starting the trowel. Failure to do so will cause

trowel blades to rotate upon starting. Once started pull

throttle towards you to start/increase rotation of blades.

Tether Safety Switch

Secure tether to your person before starting to finish.

If the handle slips out of your hand the plug will detach

from the safety switch and stop the machine. Test the

safety switch before every use. The button on top of

the tether switch can also be used to stop the engine.

Figure 14 Centrifugal Safety Switch

Figure 15 Tether Safety Switch

Figure 13 Throttle

Figure 12 Handle Adjustment Knob