15

RED

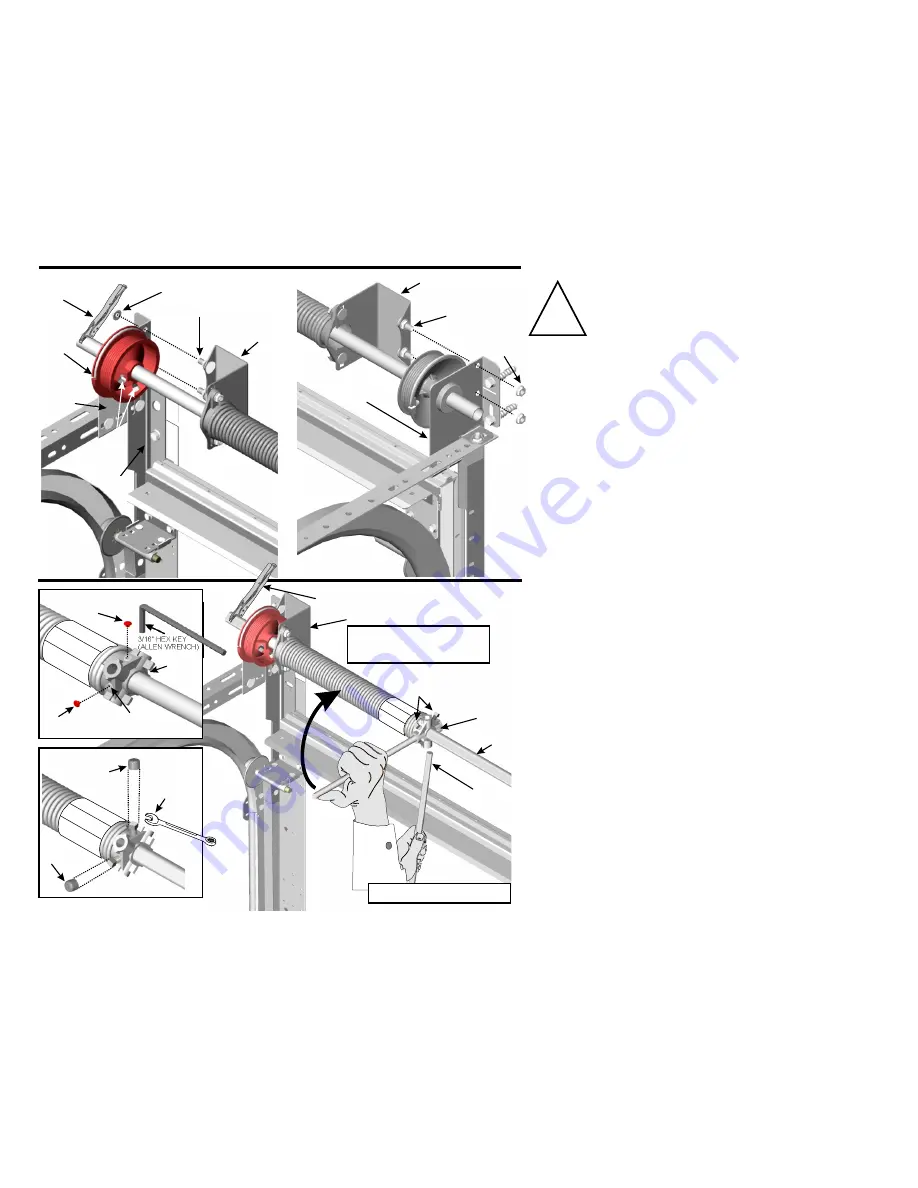

CABLE

DRUM

STEP

25

WA R N I N G ! TO R S I O N S P R I N G S C A N C A U S E

SERIOUS INJURY OR DEATH! KEEP HANDS CLEAR OF

WINDING CONES. IF NOT SURE, STOP NOW!

CALL A TRAINED MARTIN DOOR DEALER.

Check to make sure the lock is engaged, or that the door is

clamped down so it will not open. If using 4" (102) cable

drums, wind the torsion springs about 8 ¼ turns for 7' (2130)

high doors or 9 ¼ turns for 8' (2440) high doors. The

horizontal paint stripe on each torsion spring will rotate and

match each turn. Use only 1/2" (12.7) dia. high carbon steel

bars or tubes that closely fit the spring winding cone holes.

Insert the bars or tubes completely to the bottom of the

holes. (DO NOT use screw driver, etc.) Wind each torsion

spring in an upward direction 1/4 of a turn at a time. When

fully wound, tighten down the two 3/8" set screws 1/2” to 1

turn into the torsion tube. Caution: The set screws should

dimple slightly but not puncture the torsion tube. (See

Figure 19A, 19B, 19C).

To reduce the friction on the rotating spring coils, oil the

spring coils during “Final Check List”.

STEP

26

Remove the locking pliers on the torsion tube. Release the

lock or remove the clamp holding the door in place. Slowly

raise the door part way to check for balance. Be sure the

door is rolling free and not binding or rubbing. If the door is

heavy to lift, increase the torsion spring tension. If the door

goes up too fast, decrease the torsion spring tension. It is

better for the door to open a little fast than be too heavy. If

additional torsion spring adjustment is made, follow the

procedures and cautions outlined in STEP 25. Add or delete

1/4 turn at a time, alternating torsion springs. Recheck the

balance. Repeat this procedure until the door rolls smoothly

with a satisfactory balance. Be sure to clamp locking pliers

on the torsion tube and clamp or lock the door in the closed

position before each adjustment. Also read "NOTE" in

STEP 17.

After the final spring adjustment, push the GREY STEALTH

PLUGS in the HEX SOCKET SET SCREWS or the RED

SAFETY CAPS over the SQUARE HEAD SET SCREWS.

Note: Grey stealth plugs are only in 2”(51) winding cones

and 4” (102) cable drums.(See Figures 19B and 19C)

FIGURE 18A

!!

FIGURE 18B

3/8“ LOCK NUT

3/8“ X 1” SHORT

NECK CARRIAGE BOLT

LOCKING PLIERS

SIDE SPRING

ANCHOR BRACKET

LEFT LOCK-ON

SIDE BEARING

BRACKET

LIFT CABLE

3/8“ LOCK

NUT

3/8“ X 1” SHORT NECK

CARRIAGE BOLT

RIGHT LOCK-ON

SIDE BEARING

BRACKET

SIDE SPRING ANCHOR BRACKET

SET

SCREWS

SIDE SPRING ANCHOR BRACKET

LOCKING PLIERS

BLACK

SPRING

WINDING CONE

TORSION TUBE

FIGURE 19A

1/2” DIAMETER

HIGH CARBON

STEEL TUBES

OR BARS

W

NI

AR

NG

WA

RN

IN

G

W

AR

NIN

G

DANGER!

DRILLING HOLES IN THE SIDE

SPRING ANCHOR BRACKET, FOR EXTRA

FASTENING, MAY CAUSE FAILURE.

BRACKET FLEXING IS NORMAL.

HEX SOCKET OR SQUARE

HEAD SET SCREWS

RN

ING

WA

W

AR

N

NG

I

WA

RN

ING

N

WA

RN

I

G

W

AR

NIN

G

WA

RN

NG

I

FIGURE 19C

FIGURE 19B

RED SAFETY CAP

GREY

STEALTH PLUG

GREY

PLUG

STEALTH

HEX SOCKET

SET SCREW

FOR SQUARE

HEAD SET

SCREW USE

END WRENCH

ONLY

3/16” HEX KEY

(ALLEN WRENCH)

RED

SAFETY CAP

TEMPORARILY REMOVE STRUT IF MORE

SPACE IS NEEDED TO WIND SPRINGS

2” (51)

WINDING

CONES

ONLY

COPYRIGHT © 2004 MARTIN DOOR