4

STEP 3

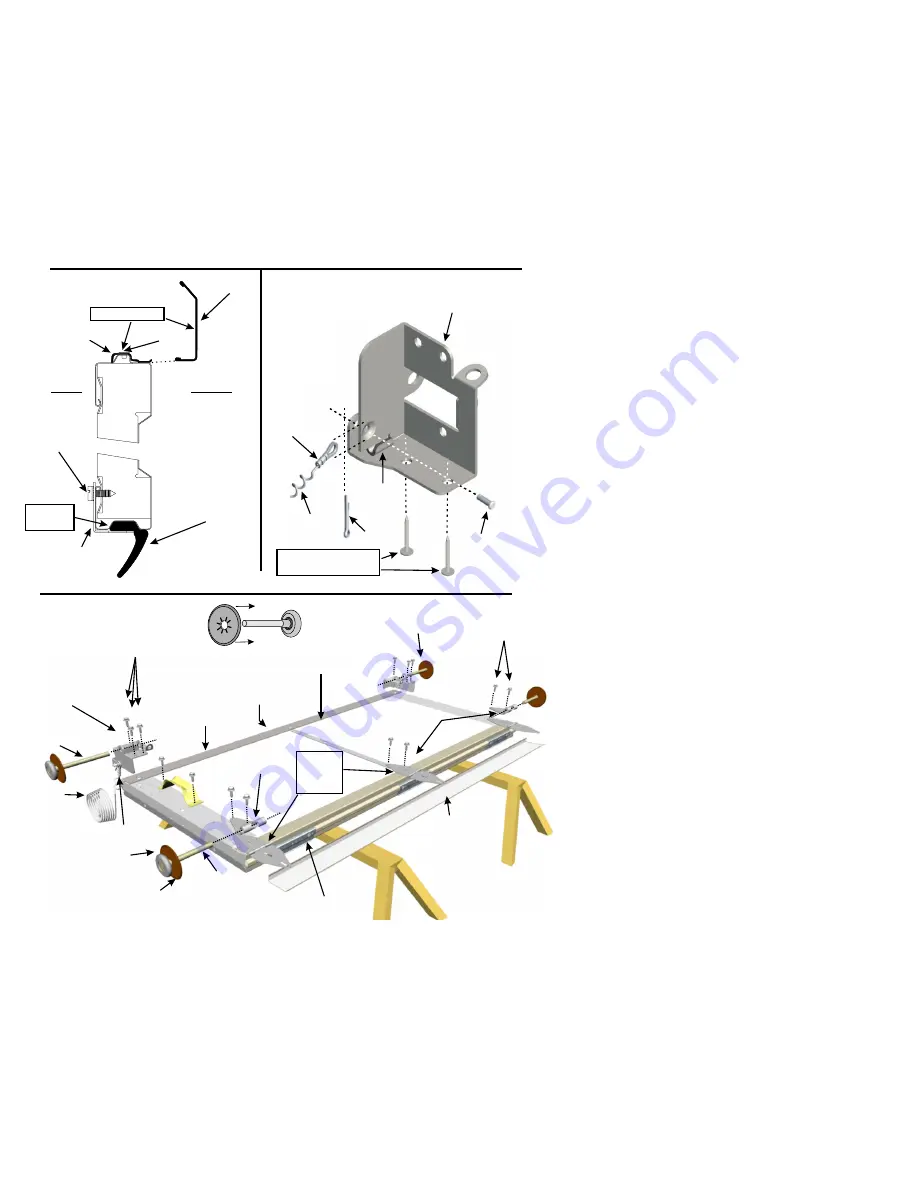

Door Section Placement.

Refer to page 2 for correct placement

of door sections. If the door has a Spring Latch Lock, the #2 door

section is the best location for the outside T-lock handle.

Bottom Reinforcing Angle and Weather Seal.

If not already

installed, loosely fasten the 1-1/2" X 1-1/2" bottom reinforcing

angle to the bottom inside edge of the #1 door section with 1/4" X 1"

thread forming screws. Fasten along the bottom of the door

section, on each stile location. Tuck the bottom weather seal under

the reinforcing angles, fitting into the configuration of the door

section. Tighten the thread forming screws to hold the bottom

weather seal tight, under the reinforcing angle. (See Figure 3)

The bottom reinforcing angle also acts as a full length step plate on

non-insulated metal doors.

STEP 4

If not already assembled, attach the lift cables to the right and left

lock-on bottom roller brackets with clevis and cotter pins. The Lift

Cable Tension Adjuster helps equalize the right and left lift cables

even if the door hits an object causing side twist. (See Figure 3A)

STEP 5

Fasten

the right and left lock-on bottom roller brackets tight

against the bottom corners of the #1 door section. Make sure the

hook on the inside of the lock-on bottom roller bracket is hooked

under the end stile on steel doors. Screws are required to lock-on

bottom roller brackets to wood doors. (See Figure 3A)

The thread forming screws go through the lock-on bottom roller

bracket, the bottom reinforcing angle, the inside return of the steel

door section, and fasten tight into the 1/8" holes in the steel or

wood stile. (See Figures 4 and 4A)

Do not

remove the plastic fasteners that are pressed into the

center stile hinge holes on metal doors. The ¼“ x 1” thread forming

screws easily penetrate and fasten through the thin plastic heads.

Fasten

the bottom half of the hinges and the #1 roller brackets to

the top of the #1 door section. Wood doors requires hinges to be

fastened face down. Insert all 4 rollers. (See Figure 4)

Note:

The “longer stem” bottom rollers add strength to the door

during earthquakes and high winds.

Also

see “Wood Door Notes” on page 22.

“RIGHT” AND “LEFT” ARE VIEWED FROM INSIDE LOOKING OUT

THROUGH THE DOOR OPENING

FIGURE 3

FIGURE 4

FINGER SHIELD™

FINGER SHIELD CLIP

RIVET

OUTSIDE

INSIDE

¼“ X 1”

THREAD

FORMING

SCREW

1“ (25) BOTTOM

WEATHER SEAL

(2 ½“ (64) OPTIONAL)

1 ½“ X 1 ½”

BOTTOM REINFORCING

ANGLE

LOCK-ON BOTTOM

ROLLER BRACKET

LIFT CABLE

ROLLER

ROLLER

SHAFT

ROLLER

SHIELD

FINGER SHIELD CLIP

(FOR STEEL DOORS)

BOTTOM

WEATHER

SEAL

#1 ROLLER

BRACKET

FINGER SHIELD™

(STEEL DOORS ONLY)

¼“ X1” THREAD

FORMING SCREWS

#1 DOOR SECTION

1 ½“ X 1 ½” BOTTOM

REINFORCING ANGLE

¼“ X 1” THREAD

FORMING SCREWS

HINGE

LIFT CABLE

TENSION ADJUSTER

LONGER STEM

ROLLER

LONGER STEM ROLLER

COPYRIGHT © 2004 MARTIN DOOR

FOR STEEL DOORS

FOR STEEL

AND WOOD

DOORS

ALL HINGES

FASTEN

FACE DOWN

ON WOOD

DOORS

FIGURE 3A

CLEVIS

PIN

COTTER PIN

HOOK

LIFT CABLE

LOCK-ON BOTTOM

ROLLER BRACKET

(INSIDE VIEW)

LIFT CABLE

TENSION ADJUSTER

SCREWS REQUIRED TO

LOCK-ON BOTTOM ROLLER

BRACKETS TO WOOD DOOR