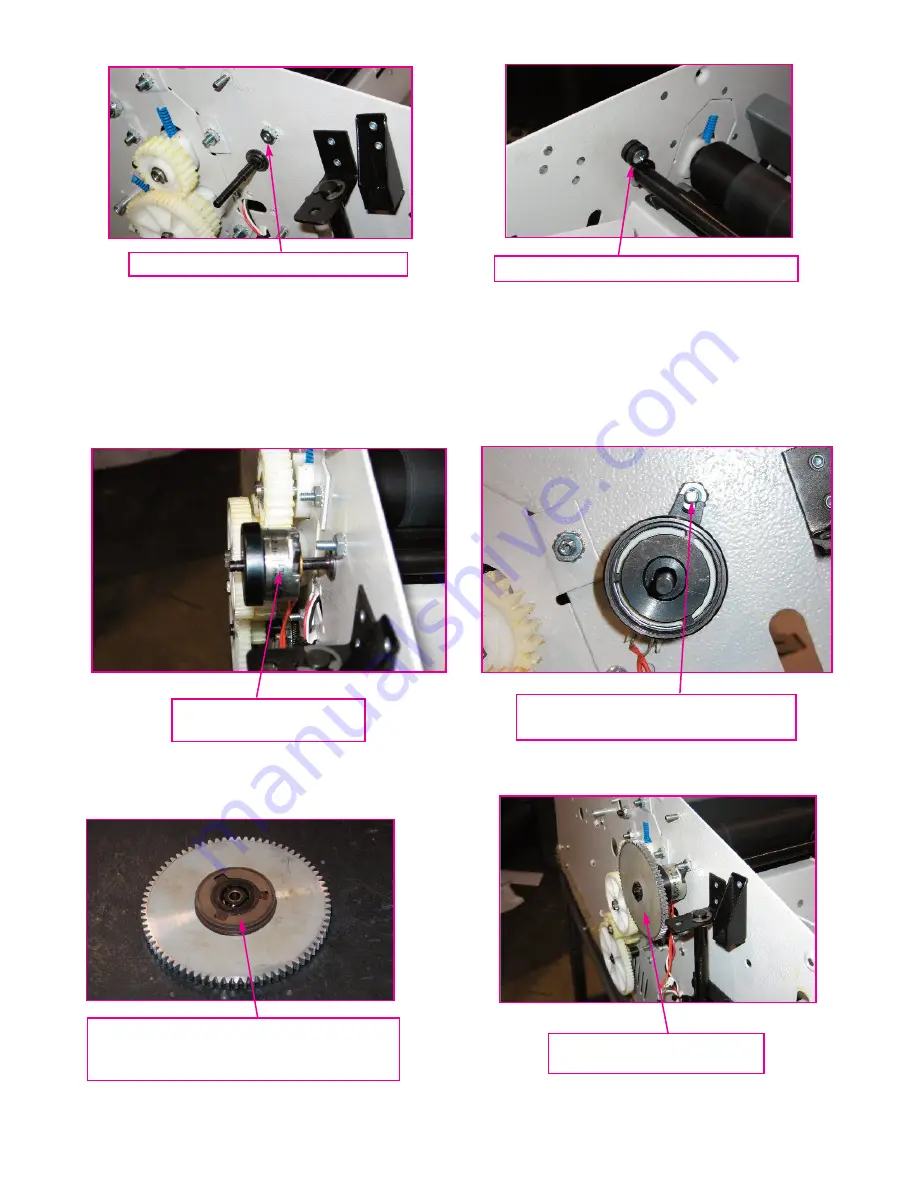

8) Install electrical body of new clutch on feed shaft. It may be necessary to turn clutch upon installa-

tion on the small end of the Feed Shaft to get their corresponding flats to align. There is a certain

amount of ‘feel’ involved with installing the electrical portion of the clutch on the feed shaft end. Do

not attempt to force the clutch onto the Feed Shaft. When the flats of the (2) components are aligned,

the clutch will slip easily on the shaft. During this installation, orient the clutch so that its anti-rotation

lugs align with the top cover grommet screw installed in step #7 above and push clutch onto shaft as

far as it will go.

9) Install new clutch gear assembly on clutch making sure that the clutch friction disk is in assembly

(held to clutch gear assembly via permanent magnet). Mesh the outer part of the gear with the exist-

ing folder gear & push on as far as it will go.

10) Install .75” OD Fender Washer received with Retro-Kit on end of feed shaft. Then install small E-

Ring to retain clutch in position.

Installing Electric Clutch

on Feed Shaft

Clutch Anti-Rotation Lugs Aligned

with Top Cover Grommet Screw

Clutch Gear Installed on

Magnetic Clutch

(4)

Make Sure that Friction Disk is at-

tached (magnetically) to Clutch Gear

with Smooth Side Towards Gear

Grommet Stop Screw & Kep Nut

Grommet Stop, Screw, and Standoff