29

8

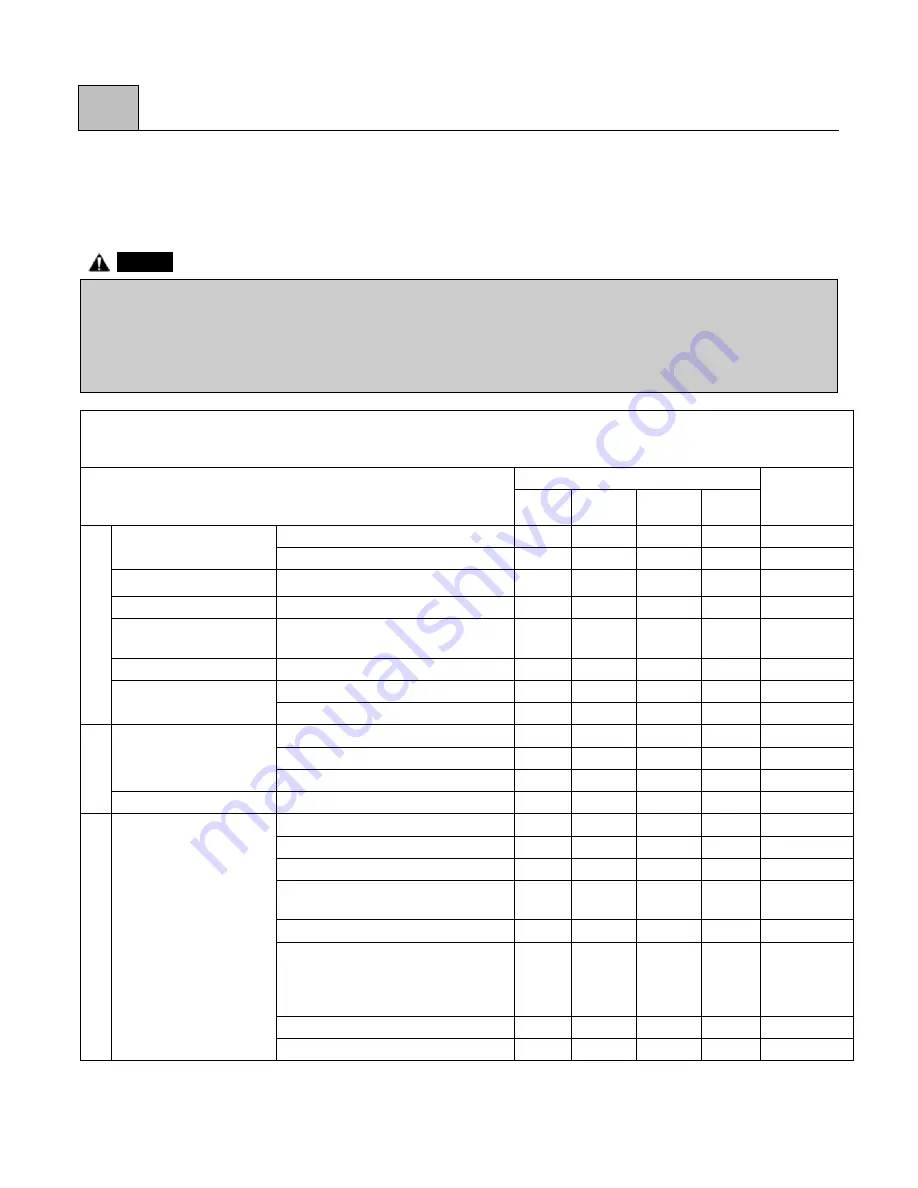

Maintenance

◼

Maintenance and Inspection (Inspection and Servicing Methods)

So that this machine can be used safely, perform the necessary periodic servicing based on the methods

explained here.

The inspection and servicing methods are divided into

“Startup inspection” and “Period inspection.” Applicable

methods are explained under each grouping.

Caution

⚫

Before performing inspection and servicing, be sure to stop the engine, apply the parking brake,

remove the ignition key, and disconnect the negative terminal end of the battery cable from the battery.

⚫

If any inspection or servicing item requires the engine to remain running, do not perform such item on

your own, but always contact the service personnel at your Maruyama dealer instead.

⚫

Dispose of the battery, oils, coolant, etc., properly after consulting your Maruyama dealer, etc.

Disposing of such items on land or in river may be punishable by law.

Periodic Inspection Standards

1. The applicable inspection timing is indicated by

.

2. The timing of initial inspection is indicated by *.

Inspection item

Inspection timing

Judgment

criterion

Start of

work

Every

6 months

Every

12 months

Hours

S

tee

ri

ng

op

erati

on

Steering wheel handle

Play, looseness, rattling

*50

Operating feel

*50

Rods and arms

Looseness, rattling, damage

*50

Knuckle

Rattling of joint

Steering device

Wheel, alignment

Toe-in:

0 mm

Steering wheel

Looseness, rattling, damage

*50

Power steering

Clogging of oil filter

Hose damage, amount of oil

B

rak

e

Brake pedal

(also used as clutch)

Catching by parking brake lever

Brake effect

*50

Activation of clutch

Rods and cables

Looseness/rattling and damage

Runn

ing

ge

ars

Wheel

Tire pressure

*50

300 kPa

Tire cracks and damage

Abnormal wear of tire

Metal pieces, stones and other

foreign matters on tire

Cracks, rattling

Looseness of bolt

*50

Wheel bolt

tightening

torque:

100 N

m

Rim damage

Rattling of wheel bearing