25

13.

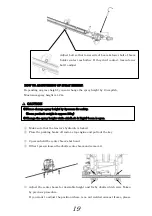

Spray work

CAUTION

①

Travel to the position where to start spraying.

②

Stop tractor in front of point which you want to start.

③

Open side boom.

(

Refer to page P18-19

)

④

Confirm whether the water feeding valve is open.

⑤

Run tractor engine at low speed and rotate PTO.

CAUTION

⑥

Operate throttle so that the PTO rpm within 580-820rpm.

CAUTION

⑦

Adjust pressure to desired level by rotating pressure adjusting dial.

⑧

Position the shift lever of tractor to required position, then travel.

⑨

Please position spray cock to “OPEN” and spraying work.

CAUTION

Lever

●

Before operation, please adjust by tractor ‘s hydraulic lever so that universal joint will

be horizontal level. If angle position is beyond above, it will cause damage to pump.

●

If you run tractor engine at high speed, then engage PTO suddenly, it may cause

pump’s trouble. So, please rotate PTO at low speed.

●

Please operate tractor’s PTO at 580-820rpm. If PTO rpm is too high or too low, it will

cause Spray unevenness and damage of pump.

●

After running out of chemical, do not run pump more than 1minutes. It will cause

trouble of pump.