_

8

_

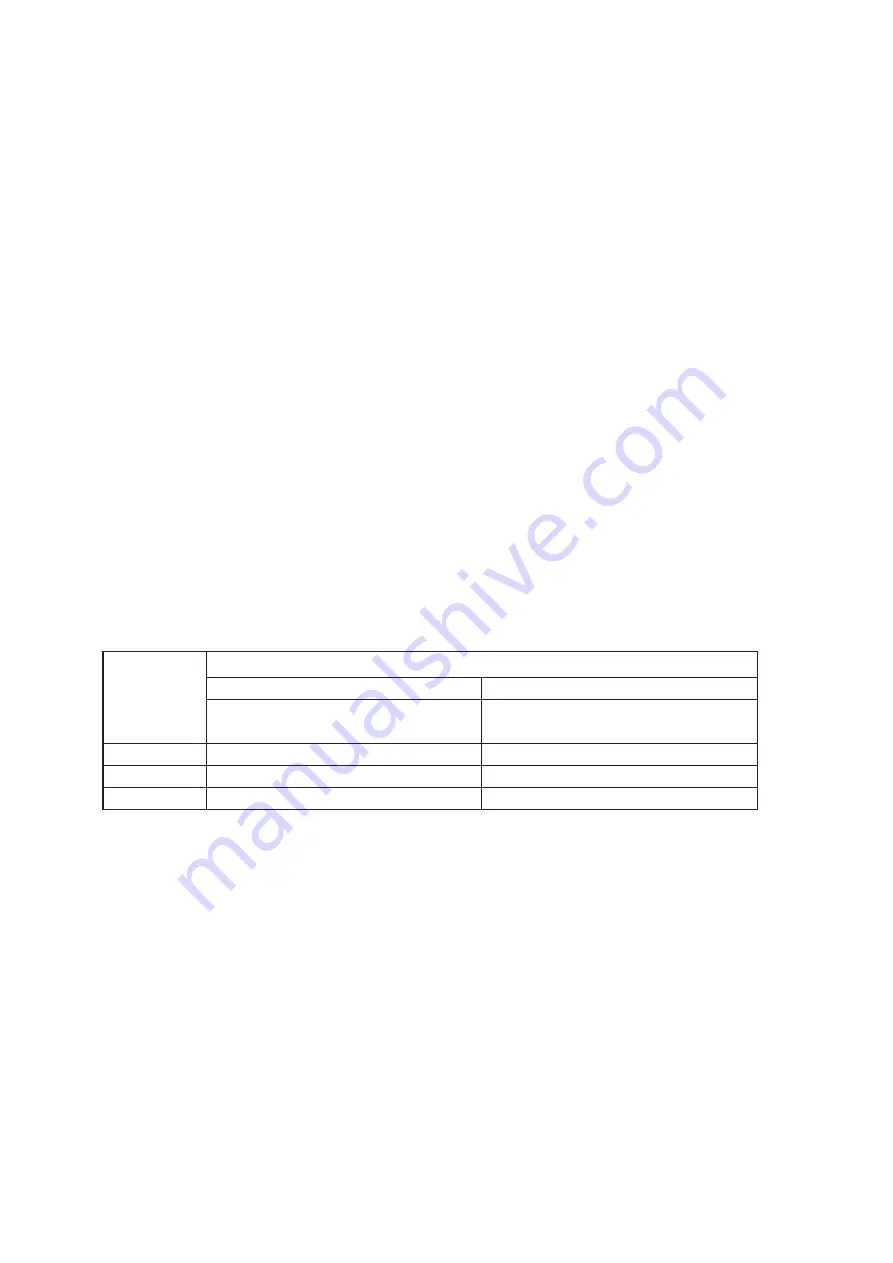

Fuel Mixture Chart

Mixing Instructions

IMPORTANT: Never mix petrol and oil directly in the Multi-Cutter fuel tank.

1. Always mix fuel and oil in a clean container approved for petrol.

2. Mark the container to identify it as fuel mix for the Multi-Cutter.

3. Use regular unleaded petrol and fill the container with half the required amount of petrol.

4. Pour the correct amount of oil into the container then add the remaining amount of petrol.

5. Close the container tightly and shake it momentarily to evenly mix the oil and the petrol before filling the

tank on the Multi-Cutter.

6. When refilling the Multi-Cutter fuel tank, clean around the fuel tank cap to stop dirt and debris from en

-

tering the tank during cap removal.

7. Always shake the premix fuel container momentarily before filling the fuel tank.

8. Always use a spout or funnel when fueling to reduce fuel spillage.

9. Fill the tank only to within 10mm from the top of the tank. Avoid filling to the top of the tank filler neck.

Petrol

Two-stroke oil

50:1

25:1

ISO-L-EGC/ EGD ,JASO class FC/ FD,

or equivalent two-stroke oil

ISO-L-EGB , JASO class FB,

or equivalent two-stroke oil

1 litre

20 mL

40 mL

2 litres

40 mL

80 mL

5 litres

100 mL

200 mL

Recommended Oil Type

Only use a two-stroke engine oil formulated for use in high-performance, air-cooled two-stroke engines.

IMPORTANT: Do not use two-stroke oil intended for water cooled outboard motors. This type of two-

stroke engine oil does not have the additives for air-cooled two-stroke engines and

can cause engine damage.

Do not use automotive motor oil. This type of oil does not have the proper additives

for air-cooled two-stroke engines and can cause engine damage.

Recommended Fuel Type

Use clean, unleaded petrol with an octane rating of 85 or higher. Use of unleaded petrol results in fewer

combustion chamber deposits and longer spark plug life. Use of premium grade fuel is not necessary or

recommended.

IMPORTANT: Never use gasohol or alcohol blended fuels in this engine.

Mixing Petrol and Oil

IMPORTANT: The engine used on this Multi-Cutter is of a two-stroke design. The internal moving

parts of the engine, i.e., crankshaft bearings, piston pin bearings and piston to cylin-

der wall contact surfaces, require oil mixed with the petrol for lubrication.

Failure to add oil to the petrol or failure to mix oil with the petrol at the appropriate

ratio will cause major engine damage which will void your warranty.