15

Water Hookup

PREPARE PLUMBING

The water valve uses a standard 1/4” (6.35 mm)

compression fitting.

Plumbing installation must observe all state and local

codes. All water and drain connections MUST BE made by

a licensed/qualified plumbing contractor. Failure to follow

recommendations and instructions may result in damage

and/or harm.

Water Supply Connection

When connecting the water supply, please note the

following:

• Before installing the unit and connecting to the cold

water supply, review the local plumbing codes.

• The water pressure should be between 20 and 120 psi

(138 and 827 kPa).

•

The water line MUST have a shut-off valve in the

supply line.

• The water line should be looped into 2 coils. This will

allow the unit to be removed for cleaning and servicing.

Make certain that the tubing is not pinched or damaged

during installation.

Do not use any plastic water supply line. The line is under

pressure at all times. Plastic may crack or rupture with age

and cause damage to your home.Do not use tape or joint

compound when attaching a braided flexible water supply

line that includes a rubber gasket. The gasket provides

an adequate seal – other materials could cause blockage

of the valve.Failure to follow recommendations and

instructions may result in damage and/or harm, flooding or

void the product warranty.Use new hose set. Do not reuse

old hose set.

INSTALLING THE WATER SUPPLY

!

WARNING

WARNING -

Connect to potable water supply only.

• Water Mineral Content:

• TDS: greater than 5 ppm (mg/l) but less than 400

ppm (mg/l)

• Hardness: less than 200 mg/l (12 gpg)

• Not recommended for use with softened water

!

CAUTION

!

CAUTION

Turn off water supply and disconnect electrical supply to

unit prior to installation. Use caution when handling back

panel. The edges could be sharp.

1.

Turn off water supply and disconnect electrical supply

to product prior to attempting installation.

2. Remove the back panel.

3. Thread water line through back panel hole (with

bushing).

4. Locate water valve inlet and connect to valve.

5. Turn on water supply and check for leaks.

6. Reinstall back panel.

!

CAUTION

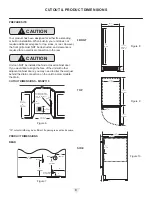

3

Figure 37

4

Figure 38