NOTE

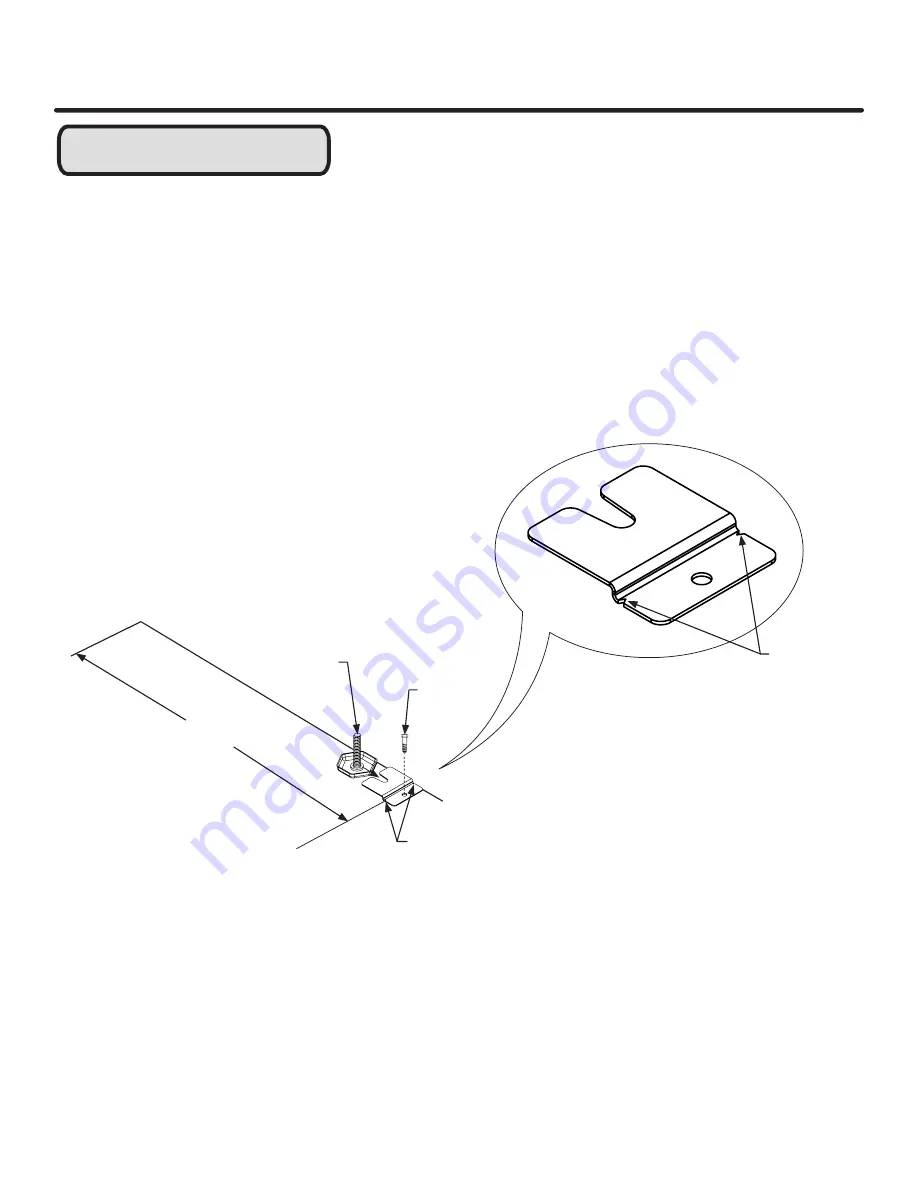

INSTALLING THE ANTI TIP DEVICE

When the floor mounted anti-tip bracket is used the mini

-

mum adjusted height of the cabinet is increased by

3

⁄

8

" (9 mm).

Figure 15a

"V" notches

in bracket

"V" notches

in bracket

Figure 15

21

1

⁄

2

"

(54.6 cm)

Front of cabinet line

Rear Leveling leg

Side of cabinet line

Rear of cabinet line

Screw

12

Summary of Contents for MPWC415

Page 31: ...31 ...