Warnings: Instructions for use

MARZOCCHI forks are based on an advanced technology coming from the company’s years long experience in the professional mountain bike

industry.

For the best results, we recommend inspecting and cleaning the area below the dust seal and the stanchion tube after every use and lubricating the

parts with some silicone oil.

MARZOCCHI forks usually offer the best performances since the very first rides. Notwithstanding this, a short running-in period may be necessary

(5-10 hours) to adjust the internal couplings. This precaution will lengthen your fork’s life and guarantee its best performances.

We recommend changing the oil at least every 100 hours.

The forks with a polished finish must be treated periodically with polishing paste to keep the exterior shining like new.

Warnings: General safety rules

After disassembling the forks, always use new, original Marzocchi seals when reassembling.

To tighten two bolts or nuts that are near each other, always follow the sequence 1-2-1, and tighten to the required tightening torque.

Before reassembly, wash all new and old components and dry them with some compressed air, making sure there are neither breaks nor burrs.

Never use flammable or corrosive solvents when cleaning the forks, as these could damage the fork’s seals. If you must use a solvent, use

biodegradable detergents that are not corrosive, non-flammable, or have a high flash point.

Before reassembling, always lubricate those components that are in contact with the fork’s oil.

If you are planning not to use your forks for a long period of time, always lubricate those components that are in contact with the fork’s oil.

Always collect and keep any lubricants, solvents, or detergents, which are not completely biodegradable in the environment. These materials should

be kept in appropriate containers, and disposed of according to local laws.

Always grease the seal lips before reassembling.

All of the components of Marzocchi forks require the use of metric tools. Use only metric tools. Imperial (US) tools may have similar sizes, but can

damage the bolts, making them impossible to loosen or tighten.

When using a screwdriver to assemble or disassemble metal stop rings, O-rings, sliding bushings, or seal segments, avoid scratching or cutting the

components with the screwdriver tip.

Do not carry out any maintenance and / or adjustment operations that are not explained in this manual.

Only use original Marzocchi spare parts.

Before servicing the fork, we recommend washing the fork thoroughly.

Work in a clean, organized, and well-lit place. If possible, avoid servicing your forks outdoors.

Carefully check to see that your work area is free of dust and metal shavings from any component of the forks.

Never modify your fork in any way.

Warnings: Fitting the fork onto the frame

The fork is supplied with “A-Head Set” steer tube to be cut to size according to frame being used.

Fitting the fork onto the bike frame is a very delicate operation that must be carried out at one of our service centres only.

The assembling on the frame and the adjustment of the steer tube must be carried out following the instructions of the steering set manufacturer.

A wrong installation can be dangerous for the rider.

Marzocchi does not guarantee the assembly and accepts no liability for damage and/or accidents arising from a wrong

installation.

The steer tube must be pressed into the crown; its replacement must be carried out by one of our service centres using the adequate tools.

A wrong installation of the steer tube into the crown may cause the rider to lose the control of the bike and lead to serious

personal injury.

Warnings: Installing the disk brake

Installing the brake system is a delicate and critical operation that must be carried out by an authorized Marzocchi Service Center.

Marzocchi is not responsible for the installation and accepts no liability for damage and/or accidents arising from this operation.

Improper installation of a disk brake system can overstress the caliper mountings, which may cause the caliper mountings to break, resulting in loss

of control of the bicycle, an accident, personal injury, or death. Be sure that the brake system installation is also performed in strict compliance with

the instructions provided by the brake system manufacturer.

Improper installation can result in an accident, personal injury, or death.

Use only brake systems that comply with the forks specifications.

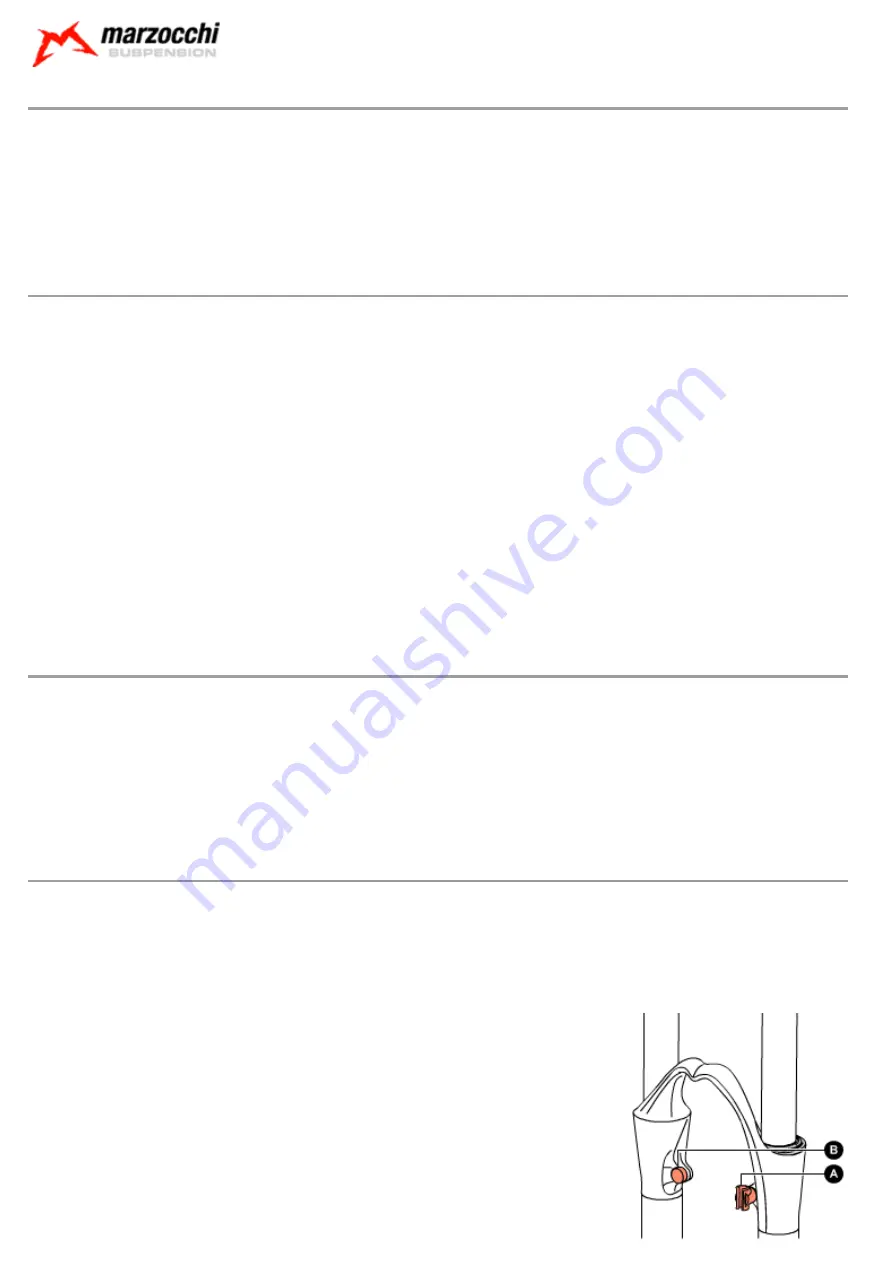

If the fork comes standard with V-brake mounts, remove such mounts and install the cable

guide (A) on the left side and cap (B) on the right side.

After installation always check that the brake tube is correctly fixed to the special mount (A).

© Marzocchi Suspension

2005

-

Marathon XC