MXC

+

ECC

Air

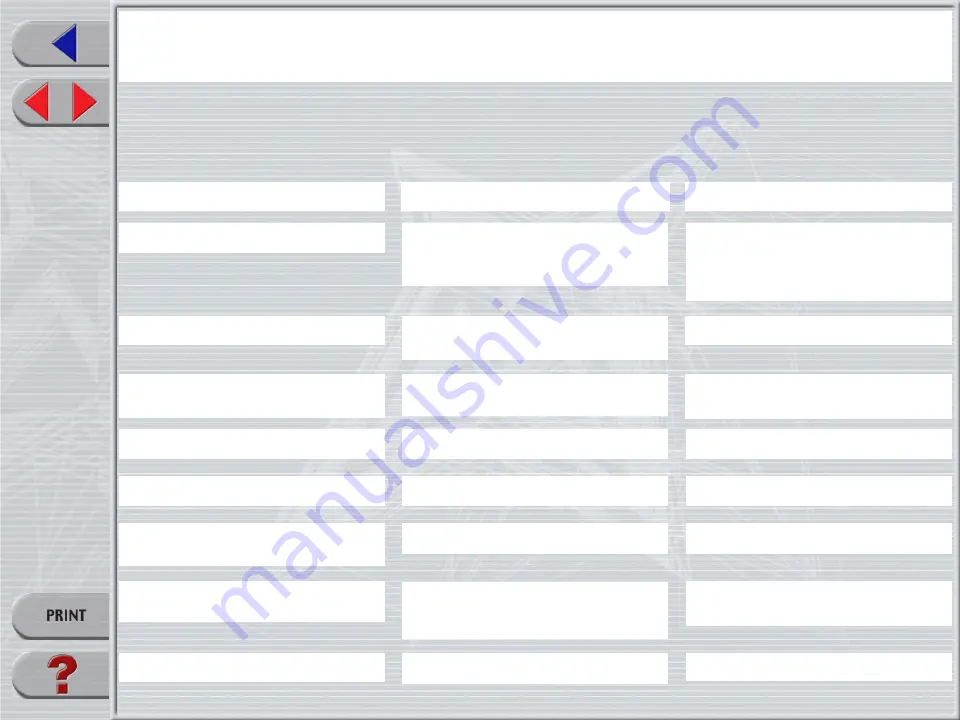

FAILURES, CAUSES AND REMEDIES

This paragraph reports some failures that may occur when using the fork. It also indicates possible causes and suggests a remedy. Always

refer to this table before doing any repair work.

FAILURES

CAUSES

REMEDIES

Adjuster position does not affect fork

operation

1. Dirt inside legs

2. Pumping element of r.h. leg does not

work properly.

1. Clean carefully and change oil

2. Replace pumping element.

Oil leaking through the bottom of slider

O-ring on the pumping rod or on cartridge

securing nut bottom damaged

Replace the O-ring

Oil leaking through the top of the slider

1. Oil seal is worn out

2. Stanchion tube is scored

3. Excessive dirt on slider oil seal

1. Replace oil seal

2. Replace crown/stanchions assembly, oil

seals and dust seals

3. Clean the oil seal seat and replace oil seal

Fork has not been used for some time and

is locked out

Oil seals and dust seals tend to stick to

stanchions

Raise dust seal and lubricate stanchion

tube, dust seal and oil seal

Pressure drop

Cap valve damaged

Replace cap and/or valve

Excessive play of stanchions in the sliders

Pilot bushings worn out

Replace bushings

Fork rebounds too fast in any adjuster

position

Dirt inside fork legs

Clean carefully and change oil

Fork does not react to rebound lock

LH fork cartridge faulty

Replace hydraulic cartridge