20

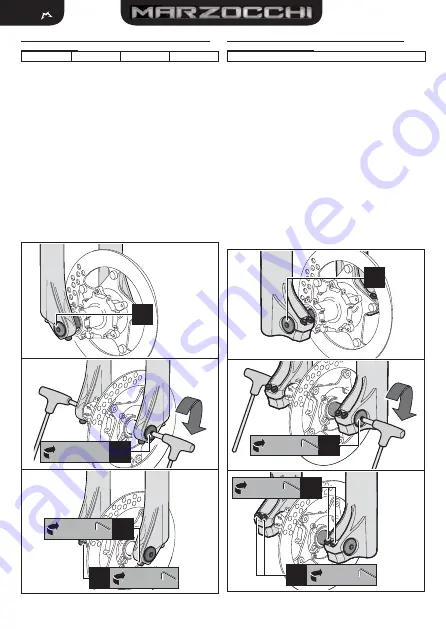

3.4.2 Wheel installation on ø32 fork with a 20 mm diameter

through-hole axle

4X

DIRT JUMPER

DJ COMP

Z1

For optimum fork performance, please follow the instructions below

when installing the wheel:

Place the wheel in between each fork.

•

Align the center of the wheel with each wheel axle clamp (see

•

3A

of

Picture 3

).

Insert the axle through the wheel axle clamp of the right fork,

•

through the wheel, and through the wheel axle clamp of the left

fork (see

3A

of

Picture 3

).

Tighten the axle to the required torque (

•

15±1 Nm

) using a 6 mm

Allen key to the axle caps (see

3B

of

Picture 3

).

Check for the proper fork-wheel alignment. To do this, begin by

•

fully compressing the fork a few times. The wheel should not

make contact with, or come close to any portion of the fork. Then

lift the front of the bicycle and spin the wheel a few times to verify

the correct alignment with the disk brake. The wheel should not

wobble from side to side or up and down. Check the owner’s

manual of the brake system for the proper speci

fi

cations.

Tighten the screw positioned on each wheel axle clamp to the required

•

torque (

6±1 Nm

) using a 4 mm Allen key (see

3C

of

Picture 3

).

3A

6 mm

15±1 Nm

3B

4 mm

6±1 Nm

3C

4 mm

6±1 Nm

3C

Picture 3 -

Wheel install on ø32 fork with a 20mm diameter through-hole axle

3.4.3 Wheel installation on ø35/ø38 forks with a 20 mm

diameter through-hole axle

888

For optimum fork performance, please follow the instructions below

when installing the wheel:

Place the wheel in between each fork.

•

Align the center of the wheel with each wheel axle clamp (see

•

4A

of

Picture 4

).

Insert the axle through the wheel axle clamp of the right fork,

•

through the wheel, and then screw it into the wheel axle clamp

of the left fork (see

4A

of

Picture 4

).

Tighten the axle to the required torque (

•

15±1 Nm

) using a 6mm

Allen key to the caps of the axle (see

4B

of

Picture 4

).

Check for the proper fork-wheel alignment. To do this, begin by

•

fully compressing the fork a few times. The wheel should not

make contact with, or come close to any portion of the fork. Then

lift the front of the bicycle and spin the wheel a few times to verify

the correct alignment with the disk brake. The wheel should not

wobble from side to side or up and down. Check the owner’s

manual of the brake system for the proper speci

fi

cations.

Tighten the screws positioned on each wheel axle clamp to the

•

required torque (

6±1 Nm

), with a “

1-2-1

” sequence, using a 4mm

Allen key (see

4C

of

Picture 4

).

4A

6 mm

15±1 Nm

4B

4 mm

6±1 Nm

4C

4 mm

6±1 Nm

4C

Picture 4 -

Wheel install on ø35/ø38 forks with a 20 mm diameter through hole axle