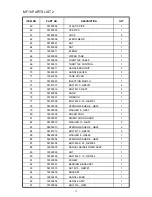

ITEM NO.

PART NO.

DESCRIPTION

QTY

59

00180006

PLASTIC PIPE

3

60

00180005

TEE PIPE

1

61

00180002

COCK 2

62

18050006

ELBOW BEND

1

63

00180501

NUT

1

64

00180502

NUT

1

65

18050011

ELBOW

1

66

18050000

WATER TANK

1

67

00180009

THROTTLE CABLE

1

68

00180010

THROTTLE CONTROL

1

69

00180011

HANDLE BAR GRIP

2

70

18060000

HANDLE LEVER

2

71

18040000

TANK COVER

1

72

00180003

INJECTION MOUTH

1

73

05781010

BOLT M10 - GB5781

4

74

09700010

BOLT M10 -GB97

4

75

00180004

KNOB

3

76

00180001

WRENCH

1

77

05781008

BOLT M8 X 30 - GB5781

1

78

09300008

SPRING WASHER 8 - GB93

1

79

09700008

WASHER 8 - GB97

1

80

18030006

BOARD PLUG

1

81

18030007

ORIENTATION BOARD

1

82

09700010

WASHER 10 - GB97

2

83

09300010

SPRING WASHER 8 - GB93

2

84

05781010

BOLT M10 - GB5781

2

85

08480008

WASHER 8 - GB848

1

86

09300008

SPRING WASHER 8 - GB93

1

87

05784008

BOLT M8 X 20 - GB5784

1

88

18030200

NANUAL RAISE/LOWER ASSY.

1

89

18030003

NUT

1

90

05784006

BOLT M6 X 10 - GB5784

1

91

18030005

SCREW

1

92

00180301

BEARING & BRACKET

1

93

06187010

NUT M10 - GB6787

1

94

18030400

BRACKET

1

95

18030405

HANDL LEVER

1

96

18030404

HANDLE GRIP

1

97

07300006

BOLT M6 - GB73

1

MF16 PARTS LIST 2

12