3

EMERGENCIES

■

ALWAYS

know the location of the nearest fire

extinguisher and first aid kit. Know the location of the

nearest telephone. Also know the phone numbers of

the nearest ambulance, doctor and fire department.

This information will be invaluable in the case of an

emergency.

MAINTENANCE SAFETY

■

NEVER

lubricate components or attempt service on a

running machine.

■

ALWAYS

allow the machine a proper amount of time

to cool before servicing.

■

Keep the machinery in running condition.

■

Fix damage to the machine immediately and always

replace broken parts.

■

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, fuel

and fuel filters.

■

DO NOT

use food or plastic containers to dispose of

hazardous waste.

Ⅱ

OPERATION

Introduction/Determining the Right Machine

Congratulations on your purchase of our Cutter! You’ve

made an excellent choice! Our floor cutter has been

specifically designed as the ideal machine for the

professional contractor who is engaged in concrete and

asphalt flat sawing.

The machines used for the primary purpose of “flat”

sawing. This type of sawing is described as “flat” because

the pavement is cut somewhere close to a horizontal

plane. It is the most common type of diamond blade

cutting.

Concrete cutters in the industry are available in a variety

of types, sizes and styles, they range from manual or self

propelled in horsepower from 7-72hp. It is possible to cut

both concrete (green or cured, with or without rebar) or

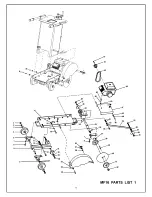

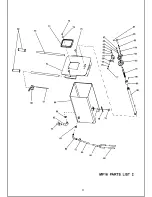

asphalt with a concrete cutter. Our MF16

utilized for jobs requiring precision cutting

including floors, pavements, walkways, ramps

and other flat sawing applications.

You will find a cutter to fit a wide variety of job

applications.

Upon receipt of your machine,

CAREFULLY

CHECK FOR

ANY FREIGHT DAMAGE.

Any

damage should be immediately reported to the

carrier and a claim registered.

Operating Principle/Delivery Checks/

Installing Blade/Types of Cutting

OPERATING PRINCIPLE

The following instructions were compiled to

provide you information on how to obtain long

and trouble free use of the unit. Periodic

maintenance of this unit is essential. Read the

manual in its entirety and follow the instructions

carefully. Failure to do so may injure yourself or

a bystander.

DELIVERY CHECKS

Immediately upon taking delivery of your new

equipment and before putting it into service:

■

Read the handbook completely—it could

save a great deal of unnecessary expense.

■

Read the engine manual supplied.

■

Check the general condition of the

equipment—has it been damaged during

delivery?

■

Check engine oil level.

■

Check fuel levels.

Recommend lubricants are detailed in the

CARE AND MAINTENANCE

section.