8

Ⅳ

LUBRICATION AND SERVICE

●

Check oil levels, wiring, hoses (air, fuel, water) and

lubricate machine daily.

●

Repair or replace all worn or damaged

components immediately.

●

Check drive belt tension, do not over-tension.

●

Make sure machine has full set of matched belts.

●

Check bladeshaft, make sure arbor and threads

are not worn, damaged, or bent.

●

Bladeshaft bearings should be tight, no free play

side-to-side or up and down.

●

Grease blade shaft bearings daily.

●

Blade collars should be clean, free of nicks and

burrs. No diameter wear and not out of round.

●

Drive pin not excessively worn or bent and free of

gouges.

●

All guards in place and secure.

●

All fasteners tight and secure.

●

Air filter/oil filter (hydraulic or engine) clean.

●

Flush clean water through the pump and spray the

assembly every night. This prolongs the pump and

blade life.

Lubricants:

Engine Oil SAE 10W/30

General Grease #1 Lithium

●

Clean machine before starting lubrication

maintenance.

●

Insure machine is on solid, level ground before

starting maintenance.

●

During lubrication maintenance insure strict

cleanliness is observed at all times.

●

To avoid the risk of accidents, use the correct tool

for the job and keep tools clean.

●

The draining of engine oil is best carried out when

the oil is warm NOT hot.

●

Any spilled oil must be cleaned up immediately.

●

Use only clean containers for oil and only CLEAN,

FRESH oils and grease of correct grade.

●

Contaminated Water/Fluids/Oils/Filters Must Be

Disposed of Safely.

Ⅴ

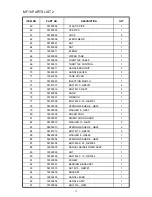

SEPECIFICATION

Motor

MF16-1 Diesel, 186 7.5kw output

MF16-2 Petrol, 188F 9.8kw output

MF16-3 Petrol, Robin EH36D 8.6kw output

MF16-4 Petrol, Honda GX390K1 9.8kw output

Weight

MF16-1 149kgs

MF16-2 126kgs

MF16-3 124kgs

MF16-4 126kgs

Max. Cutting Depth - - - - - - - - 140mm (5.5 in

)

Blade size - - - - - - - - - - - - - 300-400mm (12-16in)

Depth Adjustment Mechanism–Handle Rotation

Driving Mechanism - - - - - - - - - - Manual Push

Water Tank Capacity – - - - - - - - - - - - - - 37L

Ⅵ

WARRANTY

MASLATA products are covered by warranty for a

period of six (6) months from the date of purchase

against defects in material or workmanship

provided that:

·

The product concerned has been operated and

maintained in accordance with the operating

instructions.

·

Has not been damaged by accident, misuse or

abuse

·

Has not been tampered with or repaired by any

unauthorized person.

The owner is responsible for the cost of

transportation to and from the authorized repairer

and the unit is at the owners risk while in transit to

and from the repairer.