cod. F07011705

USE AND MAINTENANCE

ENGLISH

EN - 51

X

L max.

X

½ X

½ X

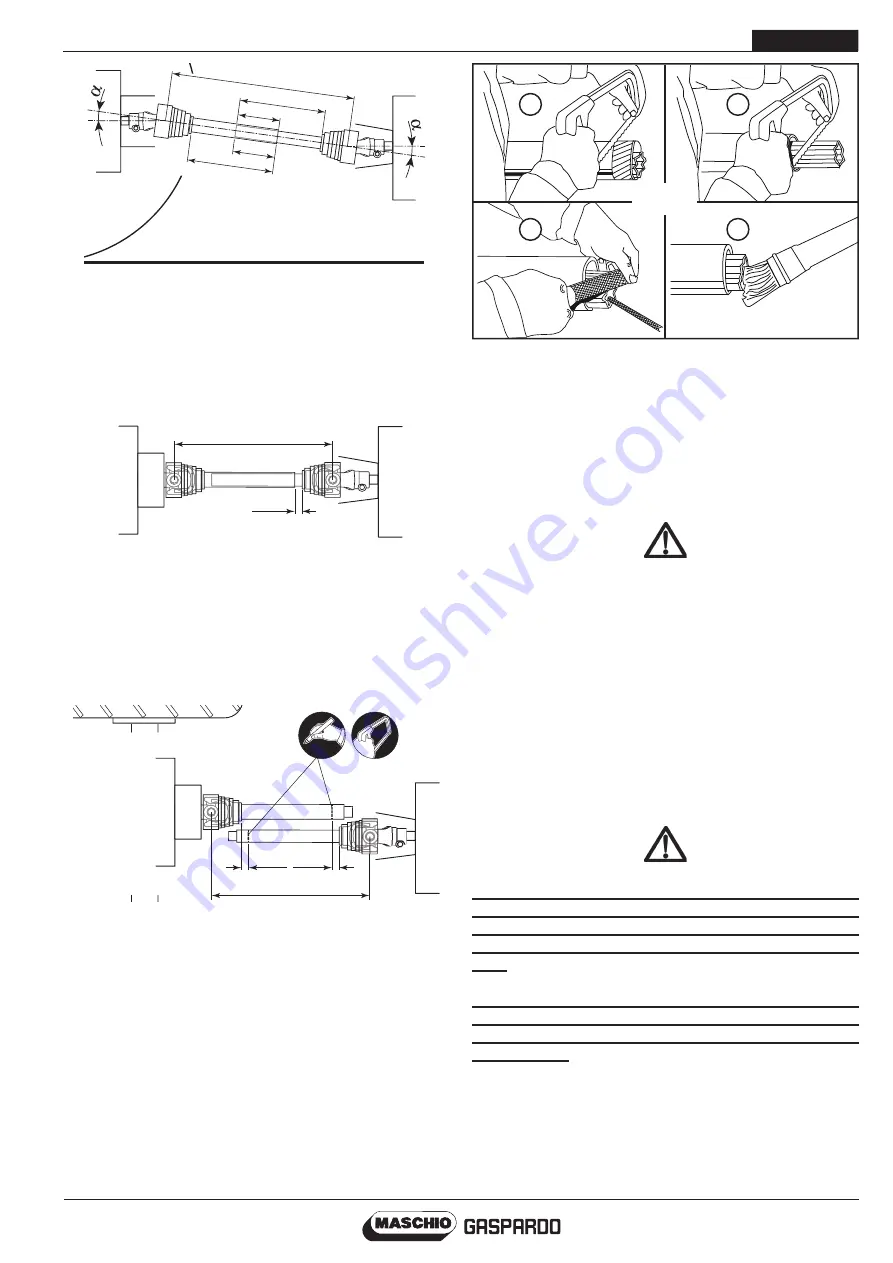

Inspections in the raised position:

- Proceed with a lifting action (tractor PTO disengaged).

- The two tubes of the driveline shaft must not fully overlap.

There must always be a safety travel of at least 4 cm.

- The angles (

α

) of the drivelines must not exceed 40°.

4 cm

L min.

If these two results are not obtained:

1) Extend the telescopic tubes completely, insert a tube

on the tractor PTO and the other on the machine. Make

sure that the telescopic tubes are locked perfectly.

2) Approach the telescopic tubes of the driveline and

fi

nd

the cutting position, taking into account the 4 cm of mi-

nimum safety clearance to guarantee against breakage.

4 cm

4 cm

L min.

3) Shorten the telescopic tubes to the detected position

(A-B, Fig. 11) (the excess part must be the same length

on both tubes), trim and clean (C, Fig. 11) and grease

the inside of the external tube (D, Fig. 11).

4) Couple the telescopic tubes and engage the entire dri-

veline on the PTO.

fi

g. 11

A

B

C

D

5) Make sure that the upper hitch bar is as parallel as pos-

sible to the lower bars of the hitch.

If this is not suf

fi

cient, correct the way the top link of the hitch

couples to the tractor or machine, as necessary, or at least

considerably attenuate, the jolts to which the driveline shaft

is subjected during the lifting phase.

CAUTION

- Telescoping tubes must always overlap by at least

1/2 of their length in normal operation and at least 1/3

of their length in all working conditions. When it is

inserted all the way, the minimum admissible play is

4 cm.

- When using the equipment on another tractor, check

that conditions are as stated above and check that

the guards complete ly cover the rotating parts of the

Cardan shaft.

The spare parts must correspond to the manufacturer’s

speci

fi

cations. Use only original spares

ATTENTION

Assemble, operate and disconnect the cardan shaft

always according to information and safety standards

supplied for shaft use, contained in the manual provided

by the shaft manufacturer and delivered with the shaft

itself.

Each cardan shaft is equipped with a use and mainte-

nance manual. Always carefully follow information and

safety standards supplied for shaft use as contained

in the manual

.

Any damage to the machine and/or persons or property

arising from failure to adhere to the above and incorrect

use of the PTO shaft are not attributable to MASCHIO

GASPARDO S.p.A. and not recognisable under warranty.

Summary of Contents for BISONTE 220

Page 6: ...cod F07011705 ITALIANO 6 IT ...

Page 35: ...cod F07011705 ...

Page 36: ...cod F07011705 ENGLISH 36 EN ...

Page 65: ...65 cod F07011705 ...

Page 66: ...cod F07011705 DEUTSCH 66 DE ...

Page 95: ...cod F07011705 GEBRAUCH UND WARTUNG DEUTSCH DE 95 ...