ENGLISH

SVENSKA

38

ITALIANO

AVVERTENZA

Tenere sempre gli olii ed i grassi al di

fuori della portata dei bambini. Legge-

re sempre attentamente le avvertenze

e le precauzioni indicate sui conteni-

tori. Evitare il contatto con la pelle.

Dopo l’utilizzo lavarsi accuratamente

e a fondo.

Trattare gli olii usati in conformità con

le leggi vigenti anti-inquinamento.

4.1 PRIME 8 ORE

LAVORATIVE

- Dopo le prime 8 ore lavorative a cui la

macchina è stata sottoposta, effettuare

un accurato controllo dello stato gene-

rale della macchina stessa.

- In particolare, dopo aver controllato

l’usura delle zappe, è bene serrare le

viti e i bulloni di tutta la macchina.

4.2 OGNI 8

ORE

LAVORATIVE

- Ingrassare le crociere dell’albero car-

danico.

- Verifi care il serraggio dei bulloni di

fi ssaggio delle zappette.

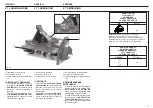

- Ingrassare i fuselli del rotore (1 Fig. 34).

4.3 OGNI 50

ORE

LAVORATIVE

- DOPO LE PRIME 50 ORE SOSTITU-

IRE L’OLIO DELLA SCATOLA DEL

RIDUTTORE.

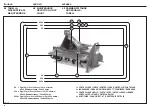

- Verifi care il livello olio nella scatola del

riduttore, (2 Fig. 34), eventualmente

ripristinarlo fi no alla tacca di livello

ricavata sull’astina.

- Trasmissione laterale a catena:

Ogni 1000 ore di lavoro sostituire il

grasso di lubrifi cazione.

Smontare il carter, effettuare un la-

vaggio degli organi di trasmissione

e ripristinare con la giusta quantità di

grasso nuovo. Rimontare poi il carter

laterale.

WARNING

Always keep oils and greases well

away from children’s reach.

Always thoroughly read the warnings

and precautions indicated on the con-

tainers. Avoid contact with the skin.

Always thoroughly and fully wash

after use.

The utilized oils should be treated

in compliance with the current anti-

pollution laws.

4.1 FIRST 8 HOURS

SERVICE

- Carefully check the general condition

of the machine after the fi rst 8 hours

service.

- In particular, you are advised to fully

tighten all the screws and bolts on the

machine after having checked the hoe

blades for wear.

4.2 EVERY 8

WORK

HOURS

- Grease the cardan shaft cross jour-

nals.

- Check that the bolts fi xing the hoe

blades are well tightened.

- Grease the rotor spindles (1 Fig. 34).

4.3 EVERY 50

WORK

HOURS

- CHANGE THE OIL IN THE GEAR-

BOX OR IN THE REDUCTION UNIT

AFTER THE FIRST 50 HOURS.

- Check the level of the oil in the gearbox

or in the reduction unit and top up to

the level mark on the rod as necessary

(2 Fig. 34).

- Transmission latéral par chaine:

Every 1000 working hours, the lubrica-

tion grease must be changed. Disas-

smble the case, wash the transmission

organs, and re-assemble with the

correct quantity of new grease. Then

re-assemble the lateral case.

VARNING

Håll alltid oljor och smörjfett oåtkom-

liga för barn. Läs alltid noga igenom

varningar och säkerhetsförebyggande

texter som indikeras på behållarna.

Undvik kontakt med huden. Tvätta er

noga efter användning.

Behandla använda oljor i enlighet med

gällande miljöskyddslagstiftning.

4.1 DE FÖRSTA 8

ARBETSTIMMARNA

- Efter de första 8 arbetstimmarna ska

ni utföra en noggrann kontroll av ma-

skinens allmänna skick.

- Efter att ha kontrollerat hackknivarna,

ska ni särskilt dra åt skruvar och bultar

ordentligt över hela maskinen.

4.2 VAR 8:e

ARBETSTIMME

- Smörj kardanaxelns tvärtappar med

fett.

- Kontrollera att hackknivarnas fästbultar

är åtdragna.

- Smörj rotorspindlarna med fett (1 Fig.

34).

4.3 VAR 50:e

ARBETSTIMME

- EFTER DE FÖRSTA 50 TIMMARNA

SKA OLJAN VÄXELLÅDAN ELLER

REDUCERENHETEN BYTAS UT.

- Kontrollera oljenivån i växellådan el-

ler reducerenheten (2 Fig. 34) och fyll

eventuellt på oljan upp till nivåmärket

på mätstickan enligt behov.

- Lateral kedjetransmission:

Var 1000:e arbetstimme ska smörjfettet

bytas ut.

Montera av skyddskåpan, tvätta

av transmissionsdelarna och montera

samman dem med rätt mängd smörjfett.

Sätt sedan tillbaka sidokåpan.