C

B

A

A

cod. F07011720

24 - EN

Service lubrication

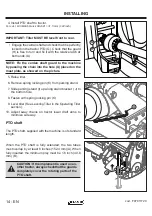

WARNING: • Firmly block tiller on horizontal surface.

• Always keep oils and greases well away from children’s reach.

• Always thoroughly read the warnings and precautions indicated on the

containers. Avoid contact with the skin.

• Always thoroughly and fully wash after use. The utilized oils should be

treated in compliance with the current anti-pollution laws.

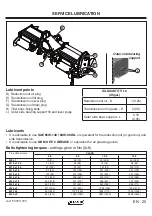

SERVICE LUBRICATION

Every 8 work hours / After every use.

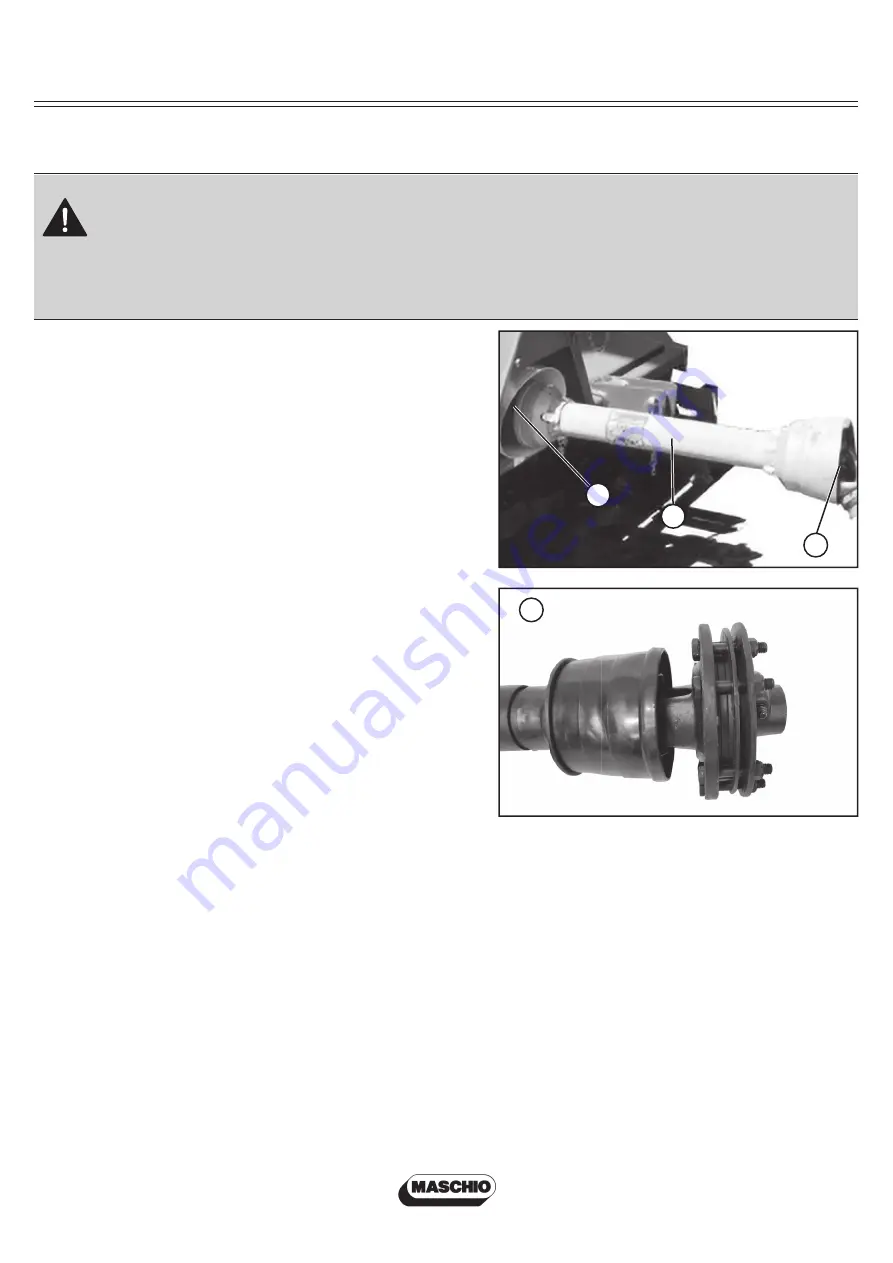

• Grease the cardan shaft cross journals (A) and (B).

• Check that the bolts fi xing the tiller tines (H) are well

tightened.

Every 50 work hours / ~Every week

(see page 25 for D, E, F, G and H)

• Check the level of the oil in the gearbox or in the reduc-

tion unit (D) and top off to the level mark on the rod as

necessary.

•

Side transmission gears

: check the level of the oil in

the side casing of the transmission unit, unscrewing

the level plug (F) and checking that oil fl ows out.

Add oil through the fi ll plug (E) if necessary. It should

fl ow from the level plug.

* To complete drain the oil from side gears, tilt the machine

forward so that oil drain through plug (G)

Every 400 work hours / ~8 weeks.

• Change the oil in the reduction unit and transmission

casing by completely draining off the old oil through

the drain plug under the reduction unit and through the

transmission drain plug.(G)

• When this operation is carried out, it is also advisable

to demount and clean the clutch disks (C). Check the

tightening of the clutch springs.

* Considering tiller working 8 hours per day.

Summary of Contents for WEEKEND WARRIOR 6042

Page 4: ...WW 6042 WW 6049 WW 6042R WW 6049R cod F07011720 4 EN TECHNICAL SPECIFICATIONS ...

Page 6: ...WW 6062 WW 6073 WW 6062R WW 6073R cod F07011720 6 EN TECHNICAL SPECIFICATIONS ...

Page 29: ...cod F07011720 EN 29 ...

Page 33: ...cod F07011720 EN 33 ...

Page 37: ...cod F07011720 EN 37 ...

Page 41: ...cod F07011720 EN 41 ...

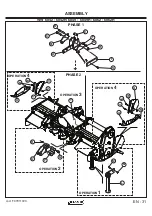

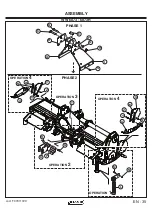

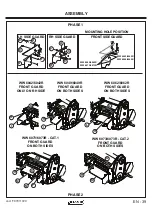

Page 43: ...A B C F D G E G H F WW 6042R 6049R 6062R 6073R cod F07011720 EN 43 ASSEMBLY ...

Page 45: ...cod F07011720 EN 45 ...