11

5.0 Operational Sequence

5.1 Before First Light-up

-

Ensure that all the packing material has been removed from the combustion chamber.

-

Make sure the St/St baffle and ceramic bricks are installed correctly and the baffle is pushed back.

Please note that the special high-temperature paint used on the heater will go through a curing process; as the

paint heats up, it will firstly soften and can be easily marked; after 2-3 burn cycles, the paint will lightly dull, and

this will indicate that it is now cured and hard. The paint will give off smoke and an odor that can irritate some

people during this process. Please ensure during the curing phase that adequate ventilation is used to open as

many doors and windows as possible to ventilate the area. Once cured, there should be no more smoke or odor.

5.2 Cold Startup

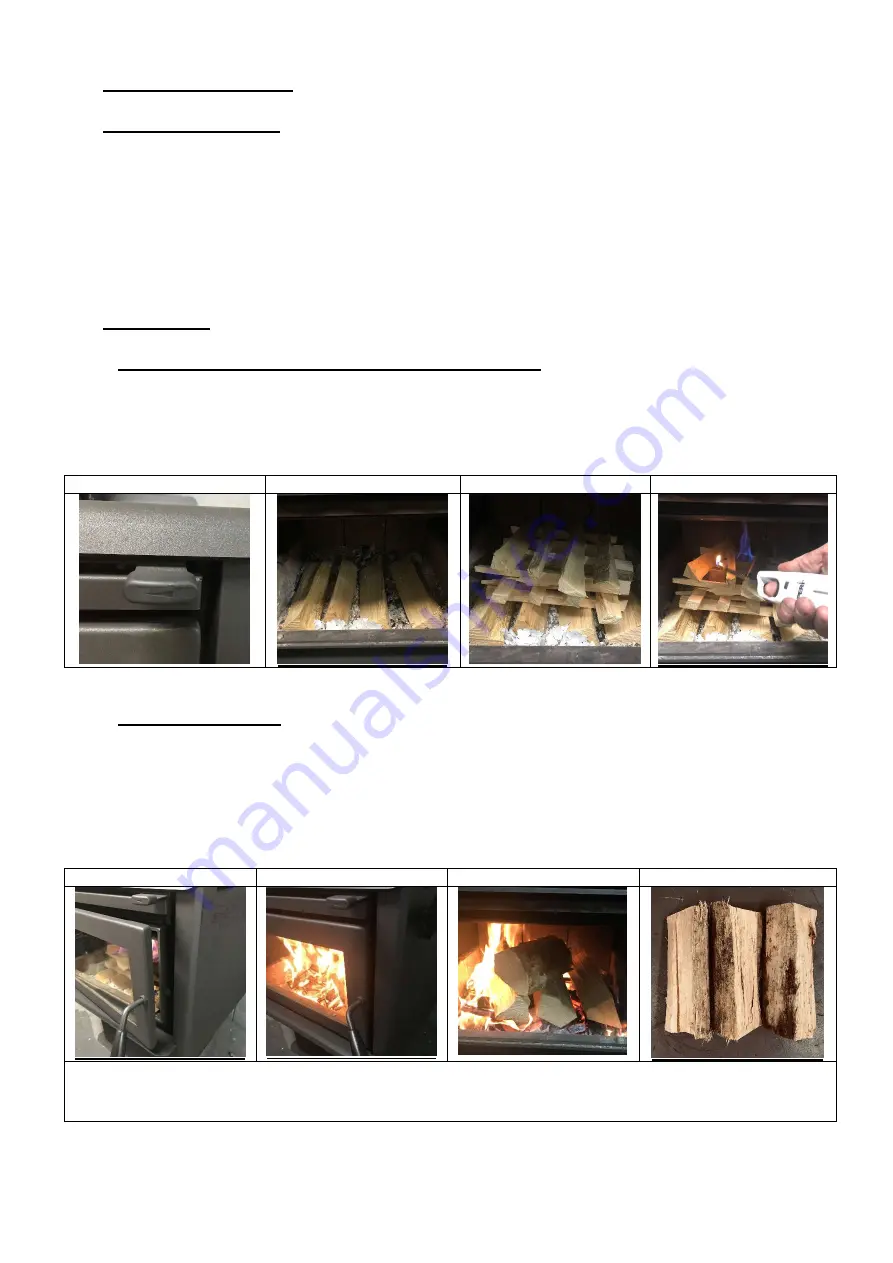

5.2.1 Initial light-up with kindling and intermediate load

1. Slide the air slide control to the

"HIGH"

position.

2. Stack intermediate load, i.e., 4 x small size logs at the base of the firebox.

3. Stack around 18-20 very small kindling pieces on top of these logs. This is the "

Top-Down Start-Up"

method, which considerably reduces particle emission during the start-up phase.

4. Place the firelighters on top of the kindling and light the fire. We recommend green firelighters made of

wood waste.

(1)

(2)

(3)

(4)

5.2.2 Intermediate load 2

5. Keep the door ajar slightly. Use the start-up latch to keep the door ajar in a controlled fashion

6. Close the door approximately

after 10 mins

making sure that the kindling is well alight. Do not change

the air slide position at this stage.

7.

After 15~17 mins

, once the small logs are more than 50% burnt, open the door to add a 2

nd

intermediate

load, i.e., 4 pieces of medium fire logs. Close the door and continue to lite the fire on the "HIGH" air slide

setting.

(5)

(6) – 10 mins

(7) – 15~17 mins

(8) – 40~45 mins

DO NOT LEAVE BURNER UNATTENDED DURING THIS INITIAL LIGHT-UP PERIOD

Summary of Contents for HURUNUI

Page 18: ...18 ...