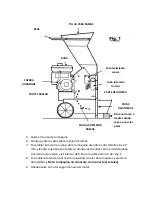

7

2. Regularly check the condition of the engine air

cleaner, especially in dusty environments.

3. The drive belt may stretch after a short period

of use, but should then stabilise for a

considerable time if not overloaded or

constantly slipped.

If the engine is not approximately level (i.e. if it

is hanging backwards away from the chute)

then the spring pressure on the belt may be

reduced causing the belt to slip.

To return the engine to level: Remove the

belt guard; loosen the 4 engine mounting bolts

using two 13mm spanners; raise the engine

mounting plate until the engine is tilting

slightly forward; pull the engine back in its

mounting slots and tighten two rear engine

mounting bolts; check that the engine is now

level; tighten the remaining engine bolts;

replace the belt guard.

NOTE: Replace the drive belt when the

engine has reached the end of its slotted

holes and it is still sloping backwards.

4. If the engine is vibrating badly, the 10mm

engine pivot bolts under the engine mounting

plate may need tightening. Do not tighten

them fully, and after tightening check that the

engine still pivots by lifting it by hand. If it does

not pivot, the belt will slip as the weight of the

engine keeps the belt tight. Removing the

pivot bolts and greasing them at least once a

year will increase the life of the pivot bushes.

New Nyloc nuts may be necessary after

removing them a few times.

5. To

remove

the

chipper

blade

for

sharpening/replacement.

•

Disconnect the spark plug lead from the

spark plug.

•

Loosen

the

upper

bolt

on

the

maintenance cover plate and remove the

lower bolt.

•

Remove the plastic shredder chute.

•

Rotate the maintenance cover plate to

expose the hole under the plate.

•

Rotate the shredder-chipper rotor until

the chipper blade is opposite the

maintenance hole.

•

With a sharp object such as a nail,

remove wooden debris from the allen key

holes in the two countersunk chipper

blade bolts.

•

Remove the bolts and the chipper blade

using an allen key and a 13mm spanner.

[BEWARE OF THE SHARP EDGE ON

THE CHIPPER BLADE.]

•

Sharpen blade to 45

o

. Do not remove

more than 2mm of material as this will

cause rotor imbalance. I.e. the minimum

blade dimensions are:

•

Never use a cracked chipper blade.

•

Use new Nyloc nuts when replacing the

chipper blade, and new bolts if they

appear damaged. Ensure the blade is

sitting flat on the rotor surface before

tightening.

!

a) 4mm Allen key.

b) 8mm spanner.

c) ¼” rod or a Phillips head screwdriver with

a shaft 6mm diameter or smaller.

d) Bearing puller.

e) Two 18mm open ended spanners.

f)

1

/

8

” Allen key.

"

1. The shredder blades can be turned 180

o

to

expose fresh cutting faces.

2. To remove the blades, first remove the

shredder chute and open the maintenance

cover near the chipper tube.

3. Remove the spark plug lead from the spark

plug.

4. Remove the belt guard.

5. Align one shredder assembly shaft with the

hole under the maintenance cover.

6. Remove the small bolts through the shredder

shaft.

7. Insert a rod or Phillips head screwdriver

through the small hole above the pulley in the

left hand plate and push the shredder shaft

out through the maintenance hole.

8. Check the condition of the shredder shaft. If it

is badly grooved (i.e. grooves greater than

1mm deep) then replace it. Similarly replace

worn spacers (see lengths below.)

9. Repeat the same operation for the other two

shredder shafts.

10. When replacing the shafts and blades, use

new Nyloc nuts on the shaft bolts and install

new bolts if they are damaged or worn. Do not

reuse cracked or badly worn blades.

11. The blades must be installed as shown above.

Of particular importance, the blade X must be

opposite the chipper blade or it will hit the

chipper blade bolts when it rotates on its own

shaft.

IMPORTANT:

CHECK THE ROTOR ASSEMBLY FOR LOOSE BOLTS &

CRACKED, WORN OR BENT PARTS AFTER EVERY 20

HOURS OF USE OR AFTER IMPACT WITH A FOREIGN

OBJECT.

REPLACE WORN OR DAMAGED PARTS.

SPACER

No.

LENGTH

(mm)

PART

No.

No. PER

1

18

536043

2

2

36

536042

2

3

51

536045

4

4

51

536044

2