18

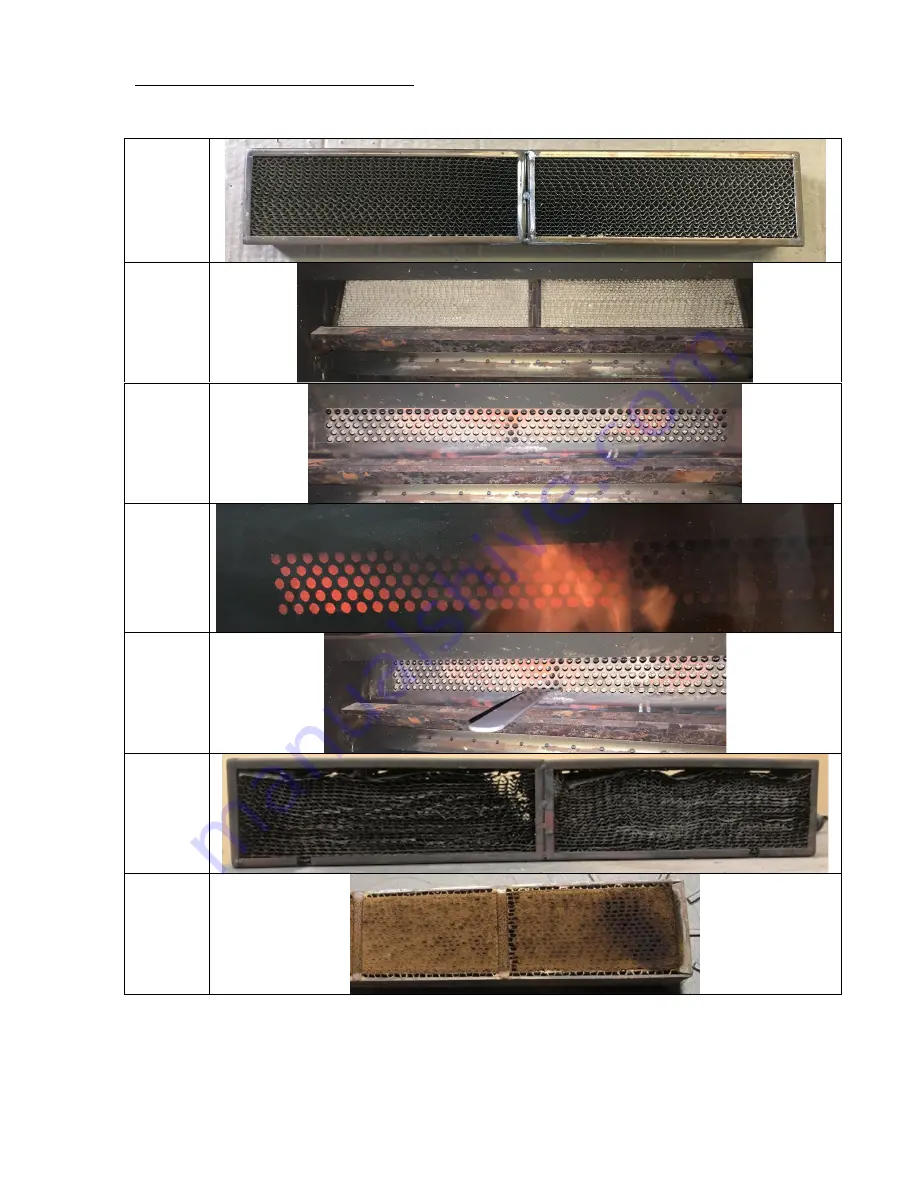

6.7 Conditions of Catalytic Combustor

Rakaia combustor pictures in different states:

New

combustor

Combustor

fitted

inside the

firebox

Flame

arrestor

plate

installed

Glowing

combustor

inside the

firebox

The tool

provided

for

removal of

arrestor

plate

Damaged

combustor

Clogged

combustor