9

3.7 Preparing the Burner for First Light-up

The Catalytic Combustor, Stainless Steel Flame Arrestor Plate, and Masonry bricks are packed loose and

separately along with the main burner. These items need to be installed carefully to make the burner ready

for use.

Glen Dimplex highly recommends NZHHA trained SFAIT (Solid Fuel Appliance Installation

technician) installer for installation of Waimakariri ULEB and carrying out the following initial set

up.

Step 1

–

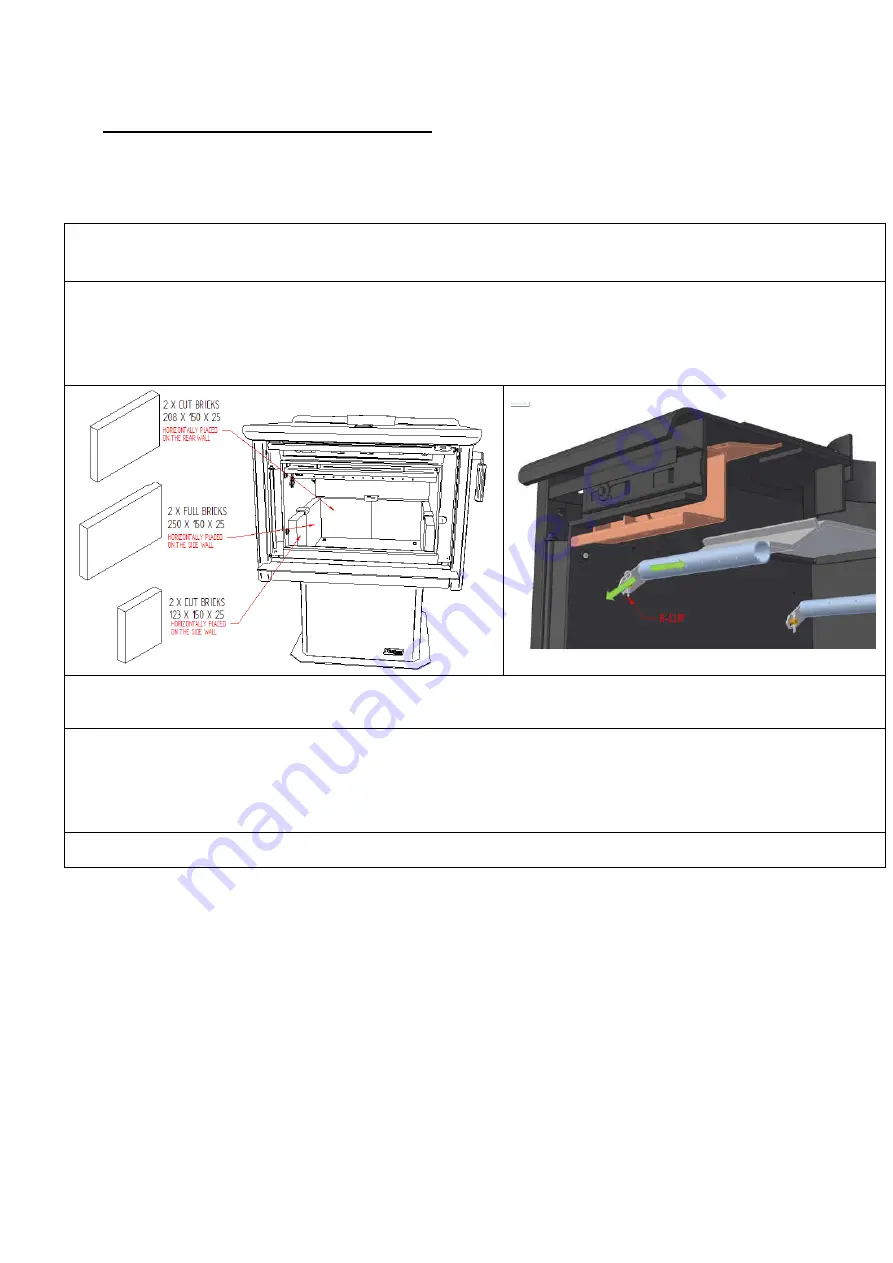

- Install Bricks in the following configurations.

- First, install two x 208 long cut bricks on the rear wall of the firebox by locking under the brick retainer.

- Then install one x 250 long full brick on each left and the right side wall of the firebox on its side edge. Push

these bricks towards the rear of the firebox.

- Lastly, install one x 123 long cut brick each on the left and right side wall towards the front of the firebox.

Step 2

–

- The baffle is already in place. Check that the baffle is locked in place by trying to move it front to back, there is a

location tab at the rear which locks it in place, and there should be no more than a couple of mm’s movement

.

Step 3

–

- The front and the rear air tubes are already in place. The front tube needs to be removed to fit the catalytic

combustor in place.

- Remove the R-clip of the front air tube.

- Slide the tube towards the right to unhook the left tab from the pin. Drop and slide the tube on the left side to

remove the tube from the firebox.

Step 4

–

- Gently lift the damper handle to the “OPEN” position and leave in that position.