15

Print Bed Leveling / Calibration

The print bed on Mass Portal printers is held in place with three

thumbscrews. The slope and height of the print bed can be

adjusted by turning the thumbscrews. As a general rule, the

printbed should not be slanted — the thumbscrews are used

to keep it level. Normally the thumbscrews would not need

adjusting by more than 1mm or 2mm at max.

Mass Portal printers have a built in sensor, that can measure the

printbed height and slant. The built in firmware (software that

runs on the printer) can use these measurements to automatically

calibrate the printer — use these measurements to set the

printhead in correct distance from the printbed. This is done to

ensure that first layer of prints is correctly printed — that it is not

too high (material not sticking to the printbed) or too low (nozzle

too close to the printbed, material “smeared” into printbed).

It is not neccessary to use automatic calibration before each print,

or even regularly. If the first layer of the print is correctly printing,

there is no need to recalibrate the printer. The printer can go for

a long time before needing to be recalibrated.

Automatic Calibration

To use automatic calibration, on the printer control panel:

1. Press

OK

button to bring up the main menu

2. Scroll down, select

Calibration

3. Select

Calibrate Printbed

4. The printhead will move down to make the measurements

5. You will see a message on screen, confirming that the printer

has been calibrated. You can print now.

WARNING

Before automatic

calibration the inner screw

should not poke out from any of

the thumbscrews (they should

be approximately level) — the

thumbscrews MUST NOT be

screwed in till lowest possible

position. The printbed must have

some play, so the springs below

it can compress — you must be

able to move printbed down a bit

when pressing on it. This is also

a safety measure in case if the

printhead moves too low.

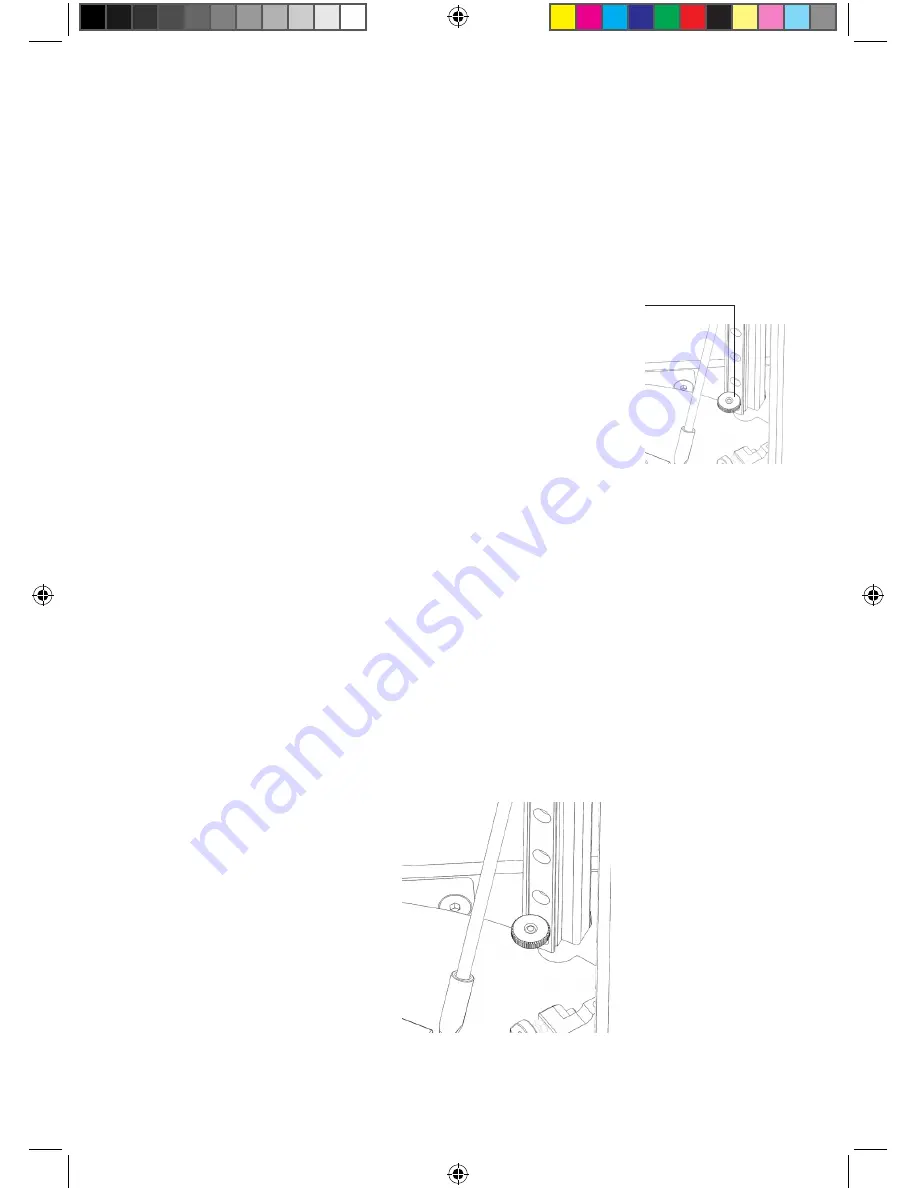

TIP

The printbed can

be leveled manually

by adjusting the

three thumbscrews

that hold the glass

printbed.

INFO

To

ensure correct

measurements,

Automatic calibration

works ONLY when

the printer is at room

temperature. If you

attempt using the

auto calibration when

the printer is hot,

you’ll see a warning

and the calibaration

will not be done.

WARNING

The

printhead will

move down when

calibrating to make

the measrurements.

Make sure there

are no objects or

previous prints on

the printbed before

performing the

automatic calibration,

otherwise the

printhead can hit

them.

MP Delta Manual ENG +.indd 15

15/04/15 17:03