4-6

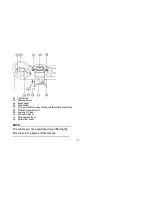

Odometer and Trip Meter Modes

Pushing the “TRIP/ODO” button switches the

display between the odometer mode “ODO”

and the trip meter modes “A” and “B” in the

following order:

ODO

→

TRIP A

→

TRIP B

→

ODO

To reset a trip meter, select it by pushing the

“TRIP/ODO” button, and then push the

“TRIP/ODO” button for at least three

seconds. The trip meters can be used to

estimate the distance that can be traveled

with a full tank of fuel. This information will

enable you to plan future fuel stops.

NOTE:

Holding in the “TRIP/ODO” button and then

turning the key to “ON” switches the display

between “mph” and “km/h”.

Clock Mode

Pushing the

button switches the

display between the clock mode “CLOCK”

and the hour meter mode “HOUR” in the

following order:

CLOCK

→

HOUR

→

CLOCK

To Set the Clock

1. Set into the clock mode.

2. Press the watch button for 3-5 seconds.

3. Press the “KM/MILE” button to set the

hours.

4. Press the “TRIP/ODO” button to set the

minutes.

5. Press the watch button for 3-5 seconds,

and then release it, the clock will begin

to work.

Summary of Contents for 700UTV-5

Page 1: ...MASSIMO ALLIGATOR 700 4 MSU 700 4 Owner s Manual ...

Page 3: ......

Page 10: ...1 1 LOCATION OF THE WARNING AND SPECIFICATION LABELS ...

Page 12: ...1 3 ...

Page 13: ...1 4 ...

Page 14: ...1 5 ...

Page 15: ...1 6 ...

Page 164: ...10 7 ...