12

11

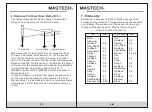

The temperature sensor has an angle of view and a

range of view, as shown in the picture below.

6. Distance To Object Size Ratio (D:S )

Make sure that the test object fully occupies the range

of view of the temperature sensor, i.e., let the sensor

“see” the test object only, without “seeing” any other

object. The larger the object is, the longer the measuring

distance must be; On the contrary, the smaller the object

is, the shorter the distance must be. Measuring distance

to size of the test object ratio (D:S ratio) is 30:1

(MS6540 series) or 50:1 (MS6550 series), as shown in

the graph below:

In order to make sure that the temperature sensor does

not receive infrared radiation from objects other than

the test object, it is advisable to carry out measurements

in a distance shorter than what is calculated according

to D:S.

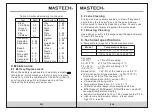

7. Emissivity

Emissivity is a measure of the radiation energy of the

corresponding material. This temperature sensor allows

you to adjust the emissivity of the sensor according to

the type of the test surface. Please refer to Table 2.

Table 2. Surface Emissivity

Test

Metal

Aluminum

Oxidized

Alloy A3003

Oxidized

Roughened

Brass

Polished

Oxidized

Copper

Oxidized

EMS

0.2

-

0.3

0.1

-

0.3

0.5

0.4

-

Test Surface

Iron

Oxidized

Rusted

Iron (Cast)

Oxidized

Unoxidized

Molten

Iron

Dull

Lead

Rough

EMS

0.5

-

0.5

-

0.6

-

0.2

0.2-0.3

0.9

0.4

Oxidized

Molybdenu

Oxidized

Nickel

Oxidized

Platinum

Black

Elec.

Haynes

Alloy

Inconel

Oxidized

Sandblasted

Electropolish

0.6

0.3

-

0.7

-

0.3

-

0.95

0.2

-

0.2

-

0.2

-

0.9

Test Object Lens Cylinder Optical Sensor