9

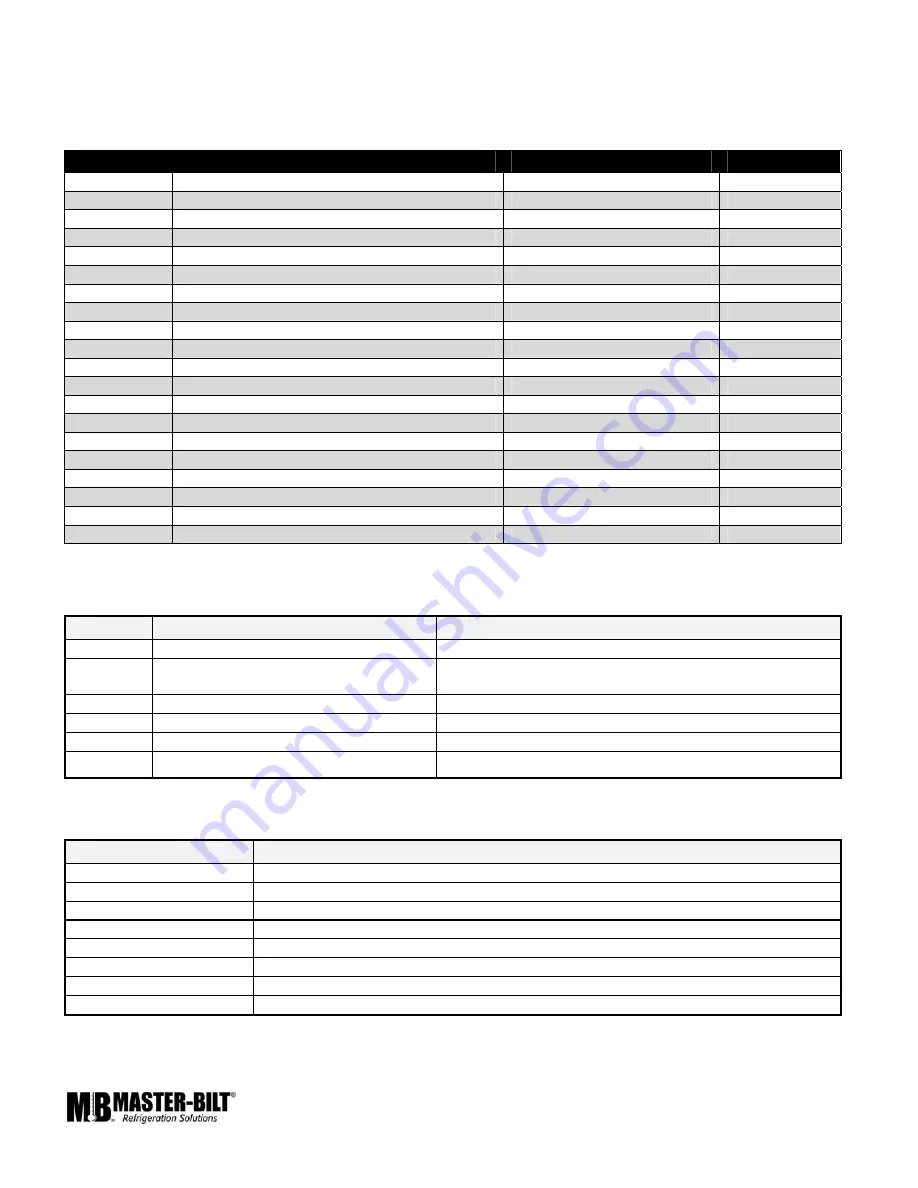

LIST OF PARAMETERS

Here is a list of factory set parameters the value of which can not be change in the field without the

password.

Symbols

Descriptions

Range

M/B Setting

SPAt

Active Set point

1 ÷ 2

1

SP1

Set Point 1

SPLL ÷ SPHL

20

SP2

Set Point 2

SPLL ÷ SPHL

20

SEnS

Probes Type

Ptc - ntc

ntc

Unit

Unit of measurement

°C - °F

°F

diSP

Normal Display (Room Temperature)

OFF - Pr1 - Pr2 - SP - CL

Pr1

HSEt

Differential

0 ÷ 30 °C/°F

5

tonE

Compressor will run for 6 minutes

OFF ÷ 99.59 min.sec

6.00

toFE

Then off for 4 Minutes

OFF ÷ 99.59 min.sec

4.00

dtyP

EL = electrical Defrost

EL - in

EL

dint

Defrosting interval

OFF ÷ 99.59 hrs.min

6.00

dEFE

Max. length of defrost cycle

0.01 ÷ 99.59 min.sec

30.00

tEdF

Defrost stop temperature

- 58 ÷ 302 °C/°F

55

tdCO

Compressor delay after defrost (drainage time)

OFF ÷ 99.59 min.sec

2.00

dLo

Defrost display

On - OFF - Lb

lb

FLt

High temperature fan off

- 58 ÷ 302 °C/°F

45

PtC

Compressor protection time

OFF ÷ 99.59 min.sec

1.00

od

Delay at power on

OFF ÷ 99.59 min.sec

0.10

HAL

High temperature Alarm threshold

OFF / - 58 ÷ 302 °C/°F

32

ALd

Temperature Alarms delay

OFF ÷ 99.59 min.sec

30

ALARM SIGNALS

Message

Cause

Outputs

-E1

Reading Outside Range

Inputs

E1

Probe 1 bad or dis connected

Control goes into fail safe mode. Compressor on 6 minutes

and of 4 minutes.

-E2

Reading Outside Range

Defrost end is timed

E2

Probe 2 bad or disconnected

Inputs

AL

Allarm in Progress

Outputs unchanged.

EEPr

Inernal Memory Error

Inputs

OTHER SIGNALS

Message

Reason

od

Delay in switching on in progress

dEF

Defrosting in progress with “dLo” = Lb

PdEF

Post-defrosting in progress with “dLo” = Lb

CC

Continous Cycle in progress

HI

Maximum temperature alarm in progress

LO

Minimum temperature alarm in progress

AL

Digital input alarm in progress

AP

Door Open