4

CAUTION!

GROUND REQUIRED

FOR SAFE OPERATION

WARNING LABELS AND SAFETY INSTRUCTIONS

This symbol is the safety-alert symbol. When you see this symbol on your cabinet or in this

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions

and safe operating practices.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses or services your cabinet is thoroughly familiar with all

safety information and procedures.

Important safety information is presented in this section and throughout this section and throughout the manual. The

following signal words are used in the warnings and safety messages:

DANGER:

Severe injury or death will occur if you ignore the message.

WARNING:

Severe injury or death can occur if you ignore the message.

CAUTION:

Minor injury or damage to your cabinet can occur if you ignore the message.

NOTICE:

This is important installation, operation or service information. If you ignore the

message, you may damage your cabinet.

The warning and safety labels shown throughout this manual are placed on your Master-Bilt Products

cabinet at the factory. Follow all warning label instructions. If any warning or safety labels become lost or

damaged, call your customer service department at (662) 534-9061 for replacements.

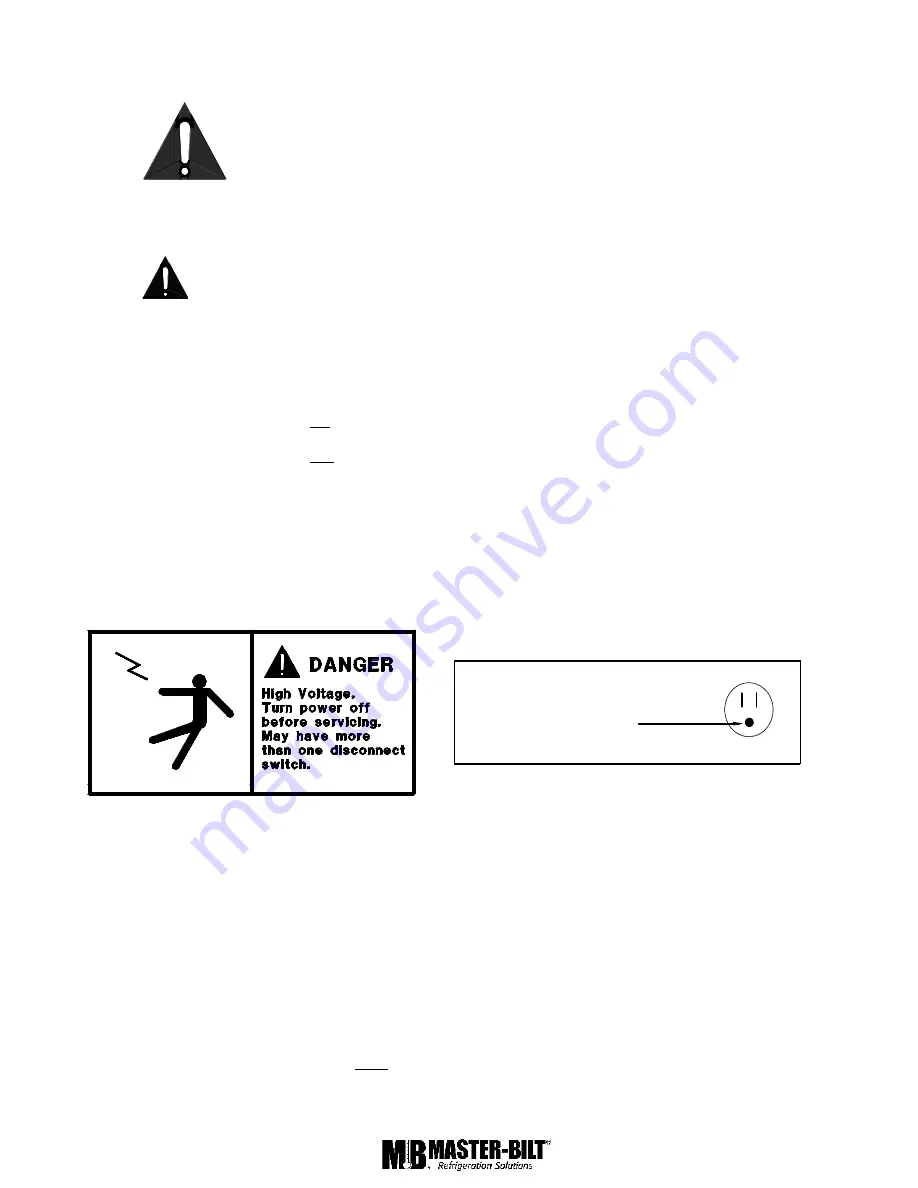

This label is located on the electrical control

This label is attached to the cabinet power cord on

box and on the rear access cover.

models with a power cord.

PRE-INSTALLATION INSTRUCTIONS

INSPECTION FOR SHIPPING DAMAGE

You are responsible for filing all freight claims with the delivering truck line. Inspect all cartons and crates for damage

as soon as they arrive. If damage is noted to shipping crates or cartons or if a shortage is found, note this on the bill

of lading (all copies) prior to signing.

If damage is discovered when the cabinet is uncrated, immediately call the delivering truck line and follow up the call

with a written report indicating concealed damage to your shipment. Ask for an immediate inspection of your

concealed damage item. Crating material must be retained to show the inspector from the truck line.