3

110522-3

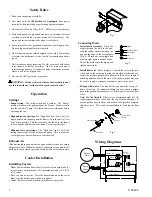

the pump from the mount slot. Remove the base of the pump (Fig.

5). Clean the pump and turn the impeller to ensure free operation.

Remove the pump spout and check for any blockage. After clean-

ing, reinstall the base onto the

pump. Press fi rmly to make sure

it is secure. Reattach the pump

to the mount in the cooler using

the plastic retainer to ensure that

the pump will not overturn. Do

not forget to replace the spout

and water delivery tube onto the

pump outlet.

Routine Maintenance

•

Drain water.

It is recommended to drain the water from the

cooler at least once a week. Keeping fresh water in the pan will

help prevent scale and mineral deposits accumulation on the pads.

Always drain all of the water out of the cooler when not in use for

prolonged periods, and particularly at the end of the season.

• Unplug unit from power supply during extended periods of

non-use.

• Cover unit or store inside when not in use.

By following the operating, installation, and maintenance suggestions

as outlined, you can get many years of effi cient and satisfactory

service from your cooler. In the event additional information is

desired, your dealer will be more than glad to assist you in every

possible way.

Maintenance

WARNING:

Before doing any maintenance be sure power is

off and unit is unplugged. This is for your safety.

Annual Maintenance

•

Oil bearings.

The blower bearings (MMBT14 only) and cooler

motor in this unit should be oiled with a few drops of non-detergent

20/30 weight oil once each year. The motor does not need oil if it

has no oil lines for oiling. Motors that have no oil lines are lifetime

oiled at the factory and require no further oiling for the life of the

unit.

CAUTION:

Do not over oil.

Over oiling can cause motor burn

out, due to excessive oil getting into motor winding.

•

Change Pads.

Pads should be replaced once or twice a season,

depending upon the length of the season. At the beginning and at

mid season a clean pad is more absorbent and effi cient and will

deliver substantially more cool air.

•

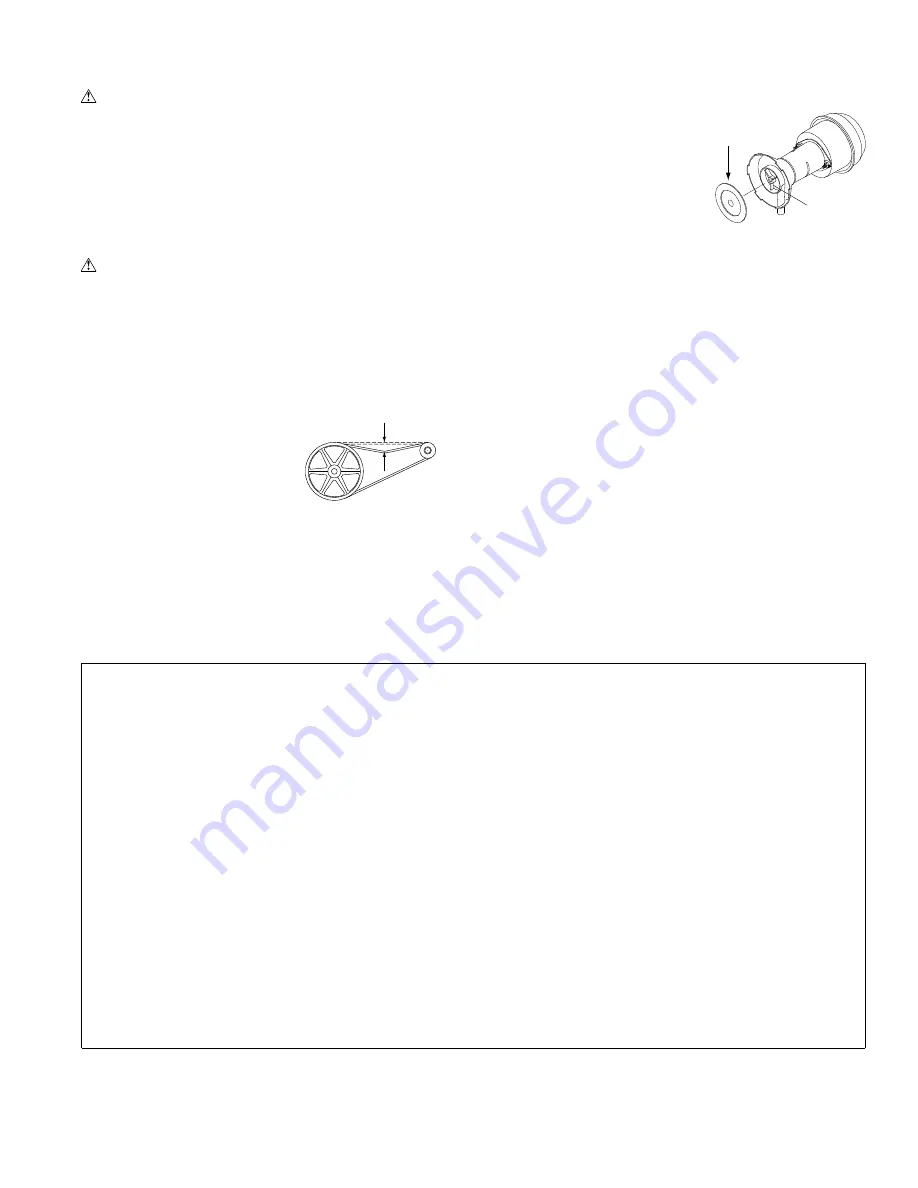

Check belt and belt tension.

This applies only to model MMBT14

which is belt driven. Model

MMBT12 has a direct drive motor.

Check the belt for any cracks or wear

and replace if necessary. Check the

tension on the belt. A 3 lb. force

should defl ect the belt 3/4 inches (see

Fig. 4). Readjust belt if needed.

•

Clean pump.

Cleaning the pump is necessary once a year at start-

up. For your safety, turn unit off and unplug unit and pump. Remove

Impeller

Remove

Base

Fig. 5

Fig. 4

3 Lb.

3/4 Inches

Limited Warranty

This warranty is extended to the original purchaser of an evaporative cooler installed and used under normal conditions. It does not cover damages in-

curred through accident, neglect, or abuse by the owner. We do not authorize any person or representative to assume for us any other or different liability

in connection with this product.

Terms And Conditions Of The Warranty

For Two Years from date of purchase, we will replace any original component provided by Champion Cooler which fails due to any defect in material or

factory workmanship only.

Exclusions From The Warranty

We are not responsible for replacement of cooler pads. These are disposable components and should be replaced periodically. We are not responsible for

any incidental or consequential damage resulting from any malfunction.

We are not responsible for any damage received from the use of water softeners, chemicals, descale material, plastic wrap, or if a motor of a higher horse-

power than what is shown on the serial plate is used in the unit.

We are not responsible for the cost of service calls to diagnose cause of trouble, or labor charge to repair and/or replace parts.

How To Obtain Service Under This Warranty

Contact the Dealer where you purchased the evaporative cooler. If for any reason you are not satisfi ed with the response from the dealer, contact the Cus-

tomer Service Department: Champion Cooler, 5800 Murray Street, Little Rock, Arkansas 72209. 1-800-643-8341. info@championcooler.com.

This limited warranty applies to the original purchaser only.

Register your product online at www.championcooler.com/index.php/cooler-warranty-registration