Page 11

OPERATION

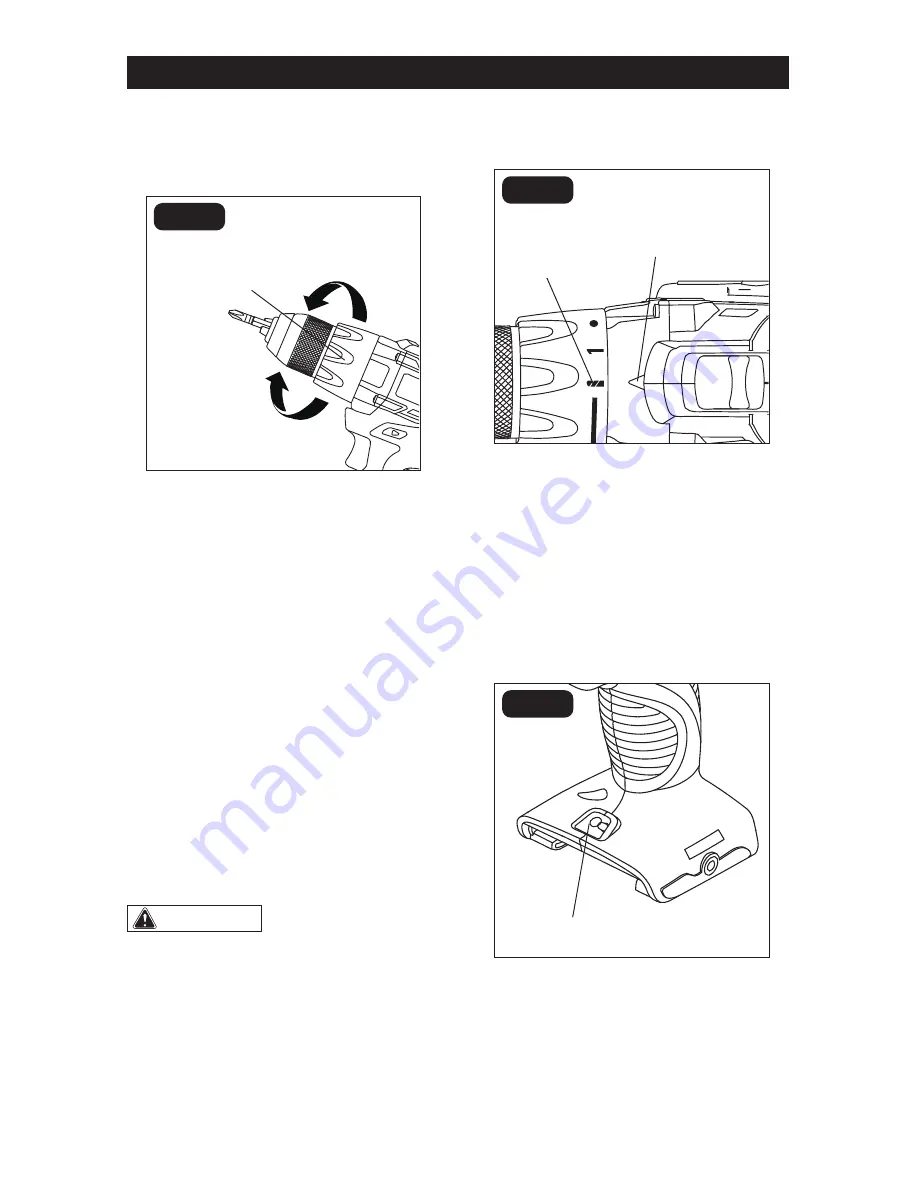

ADJUSTABLE-TORQUE

CLUTCH (FIG. 6)

FIG. 6

To increase torque

The higher the torque drill setting, the more

force the drill/driver produces to turn an

object in either low or high rotation speed.

When using the drill/driver for different

driving applications, increase or decrease

the torque in order to help prevent damage

to screw heads, threads, workpiece, etc.

Adjust the torque by rotating the torque-

adjustment ring. The proper setting depends

on the job and the type of bit, fastener, and

material you will be using.

In general, use greater torque for larger

screws. If the torque is too high, the screws

may be damaged or broken.

For delicate operations, such as removing

a partially stripped screw, use a low torque

setting. For operations such as drilling into

hardwood, use a higher torque setting.

CAUTION:

Do not change the

torque setting when the tool is running.

DRILL MODE (FIG. 7)

FIG. 7

Drill icon

Torque indicator

Select the drill mode for drilling and other

heavy-duty applications.

To select drill mode, rotate the torque-

adjustment ring until the drill icon aligns with

the torque indicator.

LED WORKLIGHT (FIG. 8)

FIG. 8

LED worklight

The LED worklight, located on the base

of the drill/driver, will illuminate when the

trigger switch is depressed before the drill/

driver is running. This provides additional

light on the surface of the workpiece. The

LED worklight will turn off when the trigger

switch is released.

To decrease torque

Torque-adjustment

ring

Summary of Contents for 241-0461

Page 18: ...Page 17 NOTES...