Page 10

OPERATION

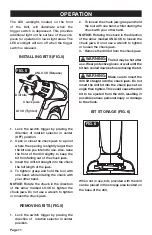

DIRECTION-Of-ROTATION

SELECTOR (fORWARD/CENTER

LOCk/REVERSE) (fIG. 2

b

)

FIG. 2b

The direction of rotation is reversible and is

controlled by a selector located above the

switch trigger. With the drill held in normal

operating position, the direction of rotation

selector should be positioned to the left of

the switch trigger for drilling. The drilling

direction is reversed when the selector is

to the right of the switch trigger. When the

selector is in center position, the switch

trigger is locked.

To stop, release switch trigger and allow the

chuck to come to a complete stop.

NOTICE

: To prevent gear damage, always

allow the right angle drill to come to a

complete stop before changing the direction

of rotation.

NOTICE

: The right angle drill will not run

unless the direction of rotation selector is

engaged fully to the left or right.

ELECTRIC bRAkE

To stop the right angle drill, release the

trigger switch and allow the tool to come to a

complete stop. The electric brake quickly

stops the chuck rotation. This feature engages

automatically when you release the trigger

switch.

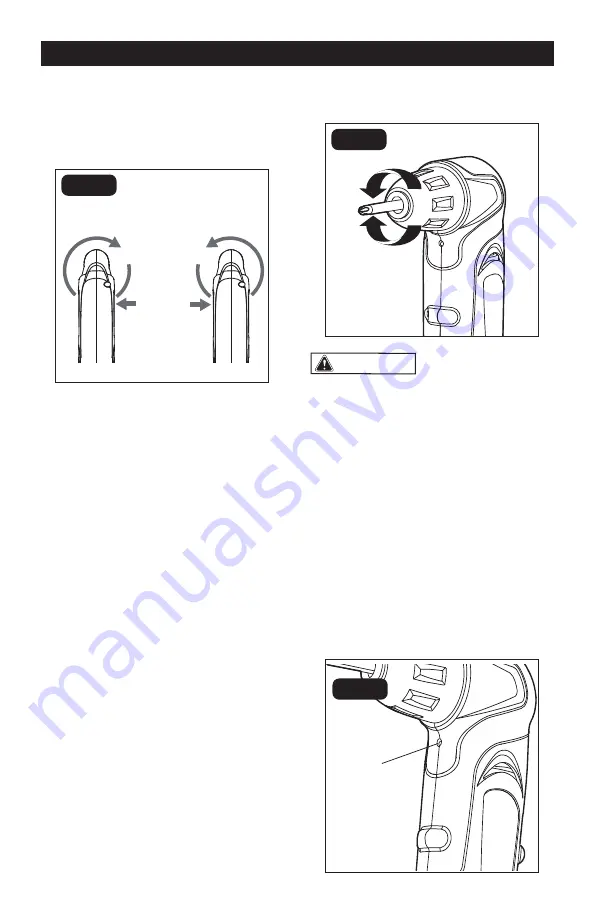

kEyLESS CHUCk (fIG. 3)

FIG. 3

WARNING:

Do not hold the chuck

with one hand and use the power of the drill

to tighten the chuck jaws on the drill bit.

The chuck could slip in your hand, or your

hand could slip and come in contact with the

rotating bit. This could cause an accident

resulting in serious personal injury.

The drill has a keyless chuck to tighten or

release drill bits in the chuck jaws. Grasp

and hold the tool with one hand. Rotate the

chuck with your other hand. The arrows on

the chuck indicate which direction to rotate

the chuck body in order to LOCK (tighten) or

UNLOCK (release) the drill bit

LED WORkLIGHT (fIG. 4)

FIG. 4

FORWARD

REVERSE

UNLOCK (Release)

LOCK (Tighten)

LED Worklight