Double insulation is a concept in safety in electric power

tools, which eliminates the need for the usual three-wire

grounded power cord. All exposed metal parts are isolated

from the internal metal motor components with protecting

insulation. Double insulated tools do not need to be grounded.

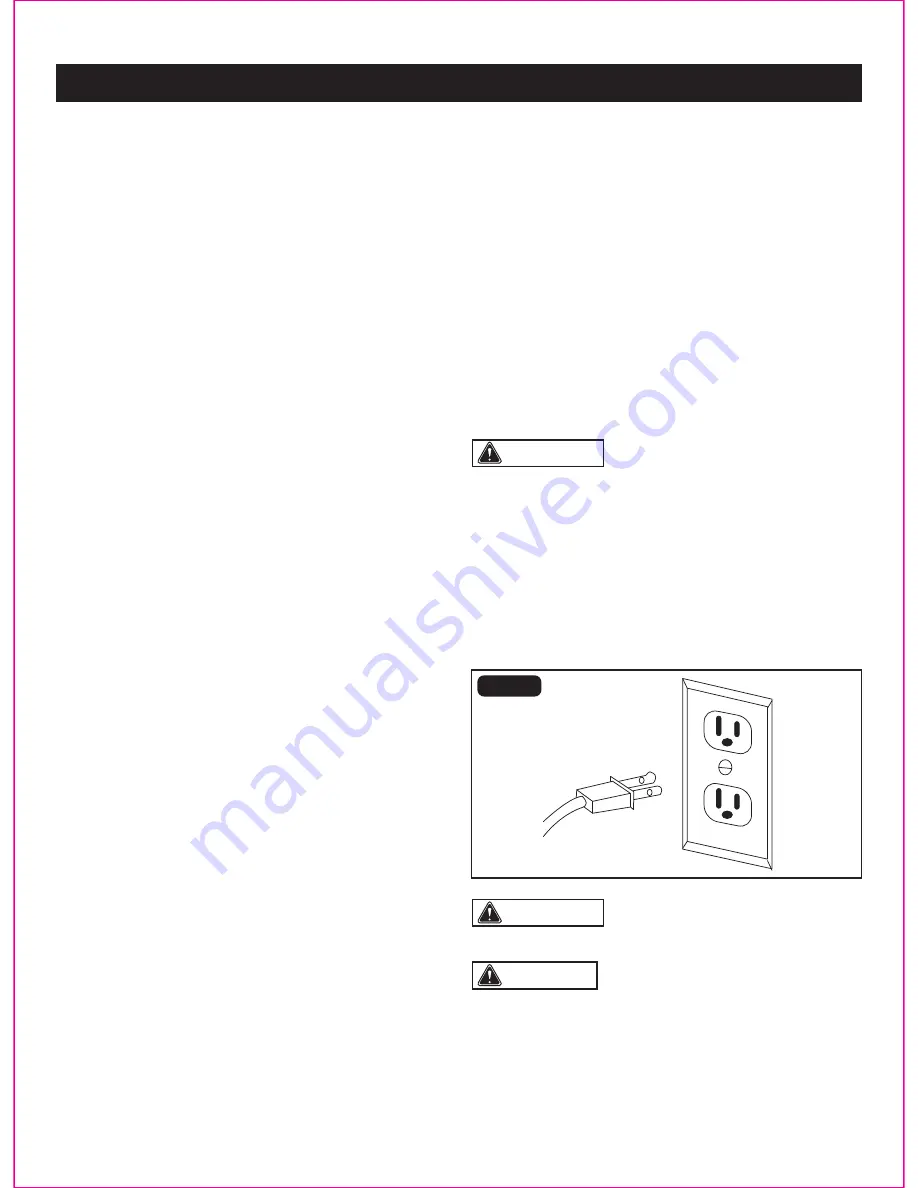

To reduce the risk of electrical shock, double-insulated

tools are equipped with a polarized plug (one blade is

wider than the other). This plug will fit into a polarized

outlet only one way.

If the plug does not fit, contact a

qualified electrician to install a polarized outlet. Do not

change the plug in any way.

DOUBLE INSULATION

break easily or cause kickback.

•

Never hold a work piece by hand if it is too small to be

clamped.

Always keep your hands clear of the “no hands”

zone.

•

Never apply lubricants to the blade when it is running.

•

Never use solvents to clean plastic parts.

Solvents

could dissolve or otherwise damage the material.

•

Do not turn the motor switch on and off rapidly.

This

could cause the blade to loosen, which could create a

hazard. Should this ever occur, stand clear and allow the

saw blade to come to a complete stop. Disconnect the

saw from the power source and securely tighten the arbor

bolt.

•

Never leave the saw unattended

while it is connected to

a power supply.

•

Keep the motor air slots

clean and free of chips or dust.

To avoid motor damage, the motor should be blown out

or vacuumed frequently to keep sawdust from interfering

with the motor ventilation.

•

Never lift this tool by gripping the cutting handle or

miter fence.

This may cause misalignment. Always lock

the cutting head in the “DOWN” position and then carry

the saw by holding the base or lift it using the carrying

handle.

•

Know your power tool. Read the Operator’s Manual

carefully.

Learn the applications and limitations, as well

as the specific potential hazards related to this tool.

Following this rule will reduce the risk of electric shock,

fire or serious injury.

•

Before beginning power tool operation, always wear

safety goggles or safety glasses with a side shield and

a full face shield when needed.

We recommend a Wide

Vision Safety Mask for use over eyeglasses or standard

safety glasses with side shields. Always use eye protection

which is marked to comply with ANSI Z87.1.

•

Protect your lungs.

Wear a face mask or a dust mask if

the operation is dusty.

•

All visitors and bystanders must

wear the same safety

equipment that the operator of the saw wears.

•

Always check the tool for damaged parts.

Before further

use of the tool, a guard or other part that is damaged

should be carefully checked to determine whether it will

operate properly and perform its intended function. Check

for misalignment or binding of moving parts, broken parts,

and any other condition that may affect the tool’s operation.

A guard or other part that is damaged should be properly

repaired or replaced by a qualified person.

•

Make sliding cuts

by pushing the saw blade down on top

of the workpiece then sliding it back toward the rear of

the saw.

DO NOT

pull the saw toward you while making

a cut.

•

This saw can tip over

if the saw head is released suddenly

and the saw is not secured to a work surface.

ALWAYS

secure this saw to a stable work surface before any use

to avoid serious personal injury.

•

Save these instructions.

Refer to them frequently and

use them to instruct others who may use this tool.

If someone borrows this tool, make sure they have these

instructions also.

SAFETY INSTRUCTIONS

Page 6

WARNING:

The double insulated system is intended

to protect the user from shock resulting from a break in the

tool’s internal wiring. Observe all normal safety precautions

to avoid electrical shock.

WARNING:

Double insulation does not take the

place of normal safety precautions when operating this tool.

CAUTION:

Servicing of a product with double

insulation requires extreme care and knowledge of the

system and should be performed only by a qualified service

technician. For service, we suggest you return the tool to

your nearest authorized service center for repair. Always

use original factory replacement parts when servicing. Do

not use power tools in wet of damp locations or expose

them to rain or snow.

FIG. 1

Summary of Contents for 240-0028

Page 44: ......