320.340.6464

10

• Personal Protective Equipment:

Wear personal protective equipment as

directed on the chemical label while servicing sprayer.

• Review Troubleshooting Table:

Review the troubleshooting table to the right

for the type of problem you are experiencing. DO NOT attempt to repair until

reading remaining steps listed below are followed.

• Empty & Flush Tank:

Empty the tank and flush the sprayer with water as

directed in the section Cleaning, Decontaminating & Storage.

• Disconnect Power/Relieve Pressure:

Disconnect power to the sprayer and

be sure all system pressure is relieved by squeezing the gun trigger.

• Perform Repairs:

Follow the directions provided in the troubleshooting table

to repair the sprayer.

Note:

Never try to unclog the sprayer nozzle by blowing through it.

• Test after Repairs:

After repairs, ALWAYS test the sprayer for leaks with

fresh water before using.

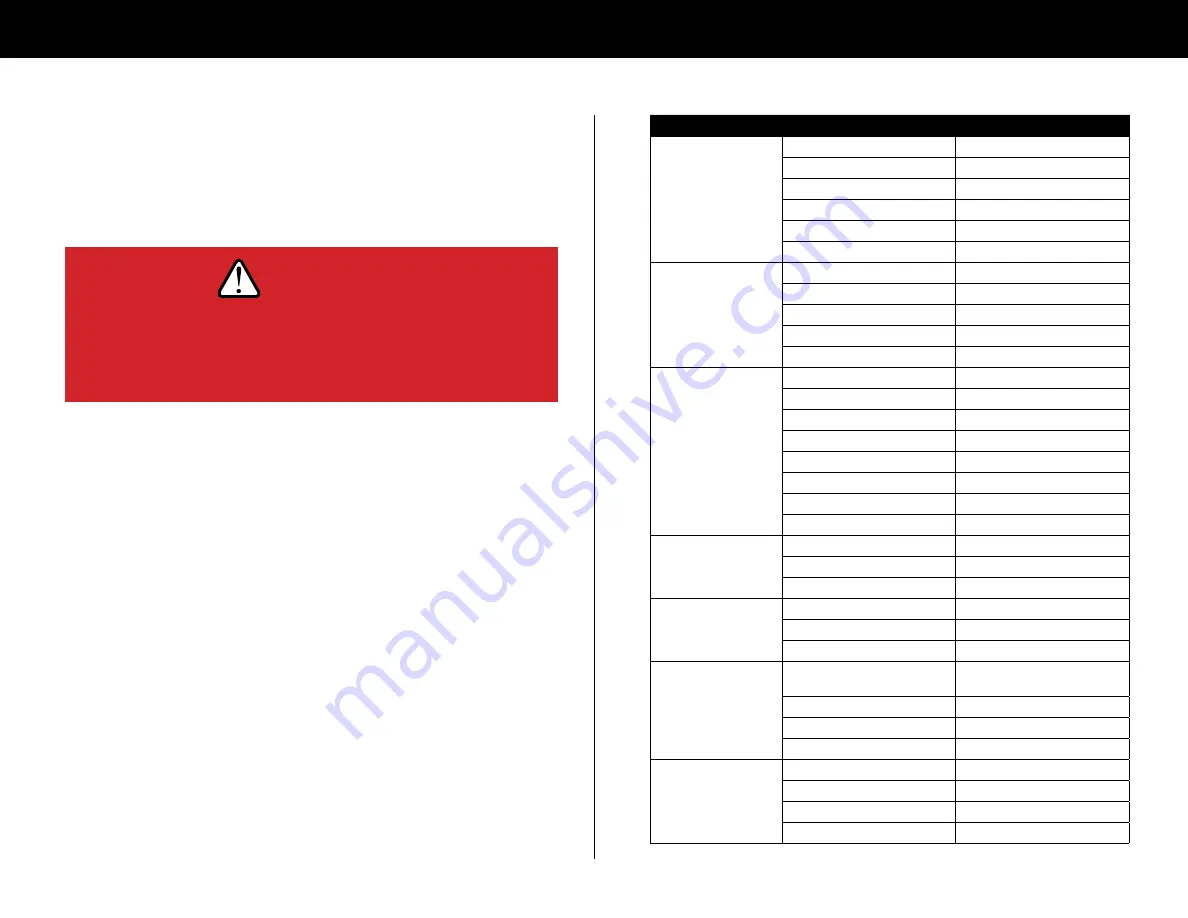

BEFORE ATTEMPTING TO SERVICE SPRAYER

WARNING

Before troubleshooting or attempting to service your pump or sprayer, read

the following safety rules to avoid accidental exposure to chemicals and the

possibility of electric shock.

TROUBLESHOOTING

Here you will find troubleshooting steps for some of the most common issues

users have with sprayers.

PROBLEM

CAUSE

SOLUTION

Pump Will Not Turn On

Bad Electrical Connection

Check Battery Connections

Fuse Blown

Replace Fuse

Short In Wire

Check Condition of Wires

Low Voltage

Check Voltage

Locked Drive

Replace Diaphragm Assembly

Faulty Pressure Switch

Replace Pressure Switch

Pump Will Not Prime

Out of Product

Refill Supply Container

Inlet Air Leak

Tighten Fittings or Replace Cracked Fittings

Inlet/Outlet Tube Obstruction

Remove Obstruction

Clogged Intake Valve

Remove Obstruction

Low Voltage

Check Voltage

Low Pressure or Flow

Worn Spray Gun Nozzle

Replace Spray Gun

Worn Boom Nozzle

Replace Boom Nozzle

Worn Wobble Plate or Diaphragm

Replace Diaphragm Assembly

Worn Pressure Switch

Replace Pressure Switch

Inlet Air Leak

Tighten Fittings or Replace Cracked Fittings

Inlet/Outlet Tube Obstruction

Remove Obstruction

Clogged Intake Valve

Remove Obstruction

Low Voltage

Check Voltage

Pump Leaks

Loose Fasteners

Tighten Fasteners

Pump Seals Degraded

Replace Pump Head Assembly

Leak In Diaphragm

Replace Diaphragm Assembly

Poor Spray Distribution

Clogged Intake Tube

Remove Obstruction

Clogged Suction Strainer

Clean Suction Strainer

Worn Spray Gun Nozzle

Replace Spray Gun

Pump Cycles While Not Spraying Leak In the System

Tighten Leaking Hose Clamps, Fittings or

Replace Spray Gun

Faulty Pressure Switch

Replace Pressure Switch

Low Voltage

Check Voltage

Air Trapped In System

Purge Air From System

Rough Operation

Flexible Mounting Surface

Mount Pump On Rigid Surface

Loose Pump Head

Tighten Fasteners

Compressed Base Feet

Decompress Base Feet

Rigid Plumbing

Plumb Pump with Flexible Pluming

ANY QUESTIONS, COMMENTS, PROBLEMS OR PARTS ORDERS

CALL OUR SPRAYING DIVISION