English–15

18.8.08

Removing Drilling Tools without

SDS-plus (see figure E)

Firmly hold the retaining ring of the quick change

keyless chuck

12

. Open the quick change keyless

chuck by turning the front sleeve in the direction of

the symbol “

”.

Remove the drilling tool.

Dust Extraction with the Extraction Device

(Accessory)

Mounting the Extraction Device

(see figure F)

An extraction device (accessory) is required for dust

extraction. When drilling, the extraction device

retracts so that the head of the extraction device is

always positioned close to the surface.

Press the button for depth stop adjustment

9

and

remove the depth stop

11

. Press button

9

again and

insert the extraction device from the front into the

auxiliary handle

10

.

Connect a vacuum hose to the extraction sleeve

15

of the extraction device.

The vacuum cleaner must be suitable for the mate-

rial being worked.

When vacuuming dry dust that is especially detri-

mental to health or carcinogenic, use a special vac-

uum cleaner.

Adjusting the Drilling Depth on the

Extraction Device (see figure G)

The requested drilling depth

X

can also be set when

the extraction device is mounted.

Insert the SDS-plus drilling tool to the stop into the

SDS-plus tool holder

1

. Otherwise, the movability of

the SDS-plus drilling tool can lead to incorrect

adjustment of the drilling depth.

Loosen wing bolt

19

of the extraction device.

Without switching the power tool on, apply it firmly

to the drilling location. The SDS-plus drilling tool

must face against the surface.

Move the guide tube

20

of the extraction device in its

holder in such a manner that the head of the extraction

device faces against the surface to be drilled. Do not

move guide tube

20

further over the telescopic pipe

18

than necessary, so that as much as possible of the scale

remains visible on the telescopic pipe

18

.

Tighten wing bolt

19

again. Loosen clamping screw

16

at the depth stop of the extraction device.

Move the depth stop

17

on the telescopic pipe

18

in

such a manner that the clearance

X

shown in the fig-

ure corresponds with the required drilling depth.

Tighten the clamping screw

16

in this position.

Starting Operation

❏

Observe correct mains voltage! The volt-

age of the power source must agree with

the voltage specified on the nameplate of

the machine. Power tools marked with

230 V can also be operated with 220 V.

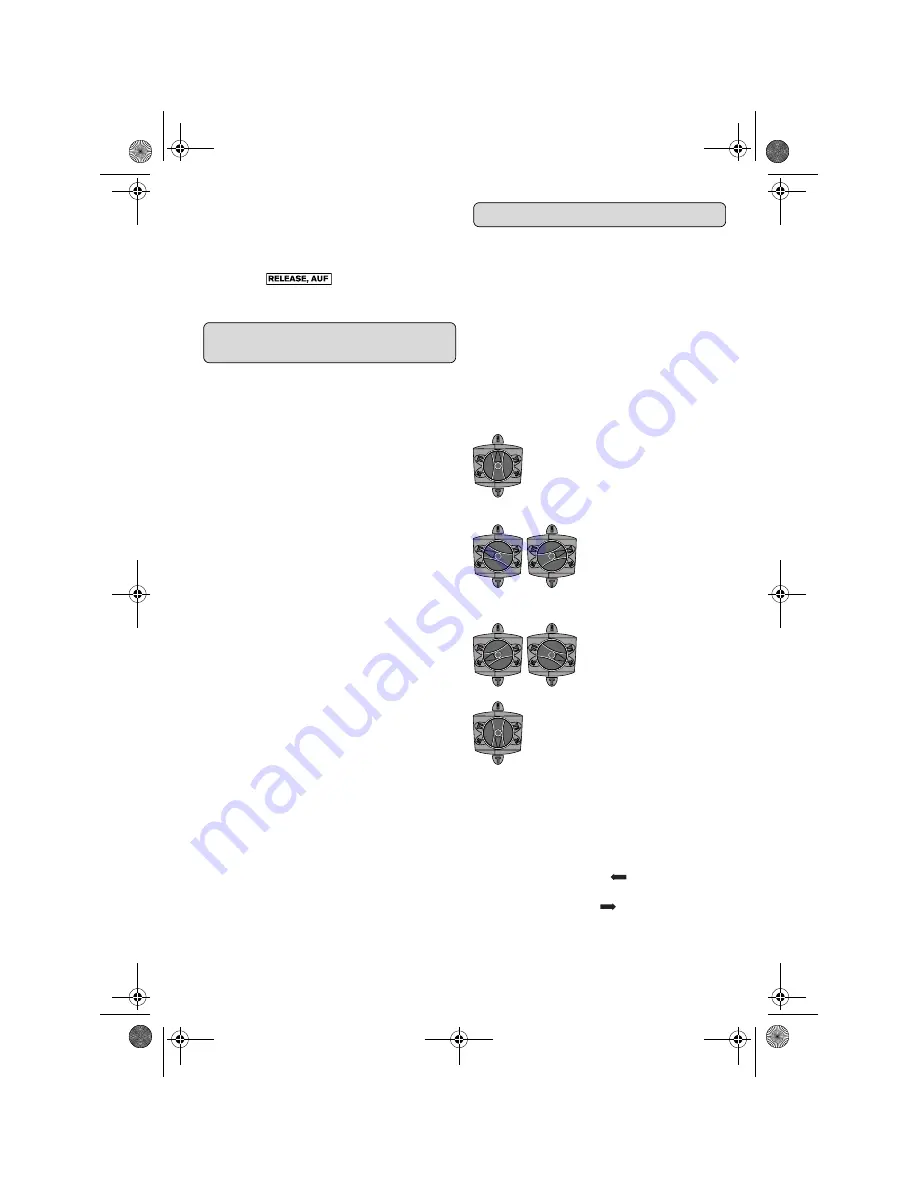

Setting the Operating Mode

The operating mode of the power tool is selected

with the mode selector switch

5

.

☞

Note:

Change the operating mode only

when the machine is switched off! Otherwise,

the machine can be damaged.

Turn the mode selector switch

5

to the requested

position.

Reversing the Rotational Direction

❏

Actuate the rotational direction switch 8

only when the machine is at a standstill.

The rotational direction switch

8

is used to reverse

the rotational direction of the machine.

Right rotation:

Turn the rotational direction switch

8

to the stop in the position

.

Left rotation:

Turn the rotational direction switch

8

to the stop in the position

.

Set the direction of rotation for hammer drilling,

drilling and chiselling always to right rotation.

Position for

drilling

without

impact in wood, metal,

ceramic and plastic as well

as for screwdriving and

thread cutting

Position for

hammer drill-

ing

in concrete or stone

When the drilling tool does

not immediately rotate upon

switching on, allow the

machine to run slowly until

the drilling tool rotates.

Position for changing the

position of the chisel

Position for

chiselling

OBJ_BUCH-820-001.book Page 15 Monday, August 18, 2008 10:25 AM