Henan Master Machinery Co., Ltd

Tel:(+86)17737606271

www.mastermachinerys.com

6

1

、

Close fuel shut off valve.

2

、

Store the unit in an upright position in a cool, dry, well

ventilated area.

3

、

Discharge fuel

(NO SMOKING!)

a. Remove the strainer cup, place the strainer over a

container and open the strainer cock to discharge

fuel from the fuel tank.

b. Remove the carburetor float chamber bolt from the

bottom and discharge fuel from the carburetor.

4

、

Engine oil

a. Change the engine oil fresh oil .

b. Remove the spark plug, pour about 5cc of engine

oil into the cylinder, slowly pull the starter handle

of the recoil starter 2 or 3 times, and reinstall the

spark plug.

5

、

Clean and store

a. Slowly pull the recoil starter handle until

resistance is felt and leave it in that position.

b. Clean the engines thoroughly with an oiled cloth, put the cover on,

and store the engine indoors in a well-ventilated, low humidity area.

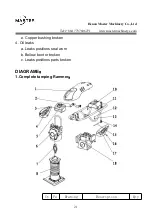

BEFORE OPERATION CHECKS

1. Check for leakage of gasoline and engine oil.

2.

Check engine oil

Notice!

Running the engine with a low oil level

can cause engine damage.

a. Before checking or refilling engine oil, be

sure the rammer is located on a stable, level