17

TIGHTENING WHEEL NUTS

– cont’d

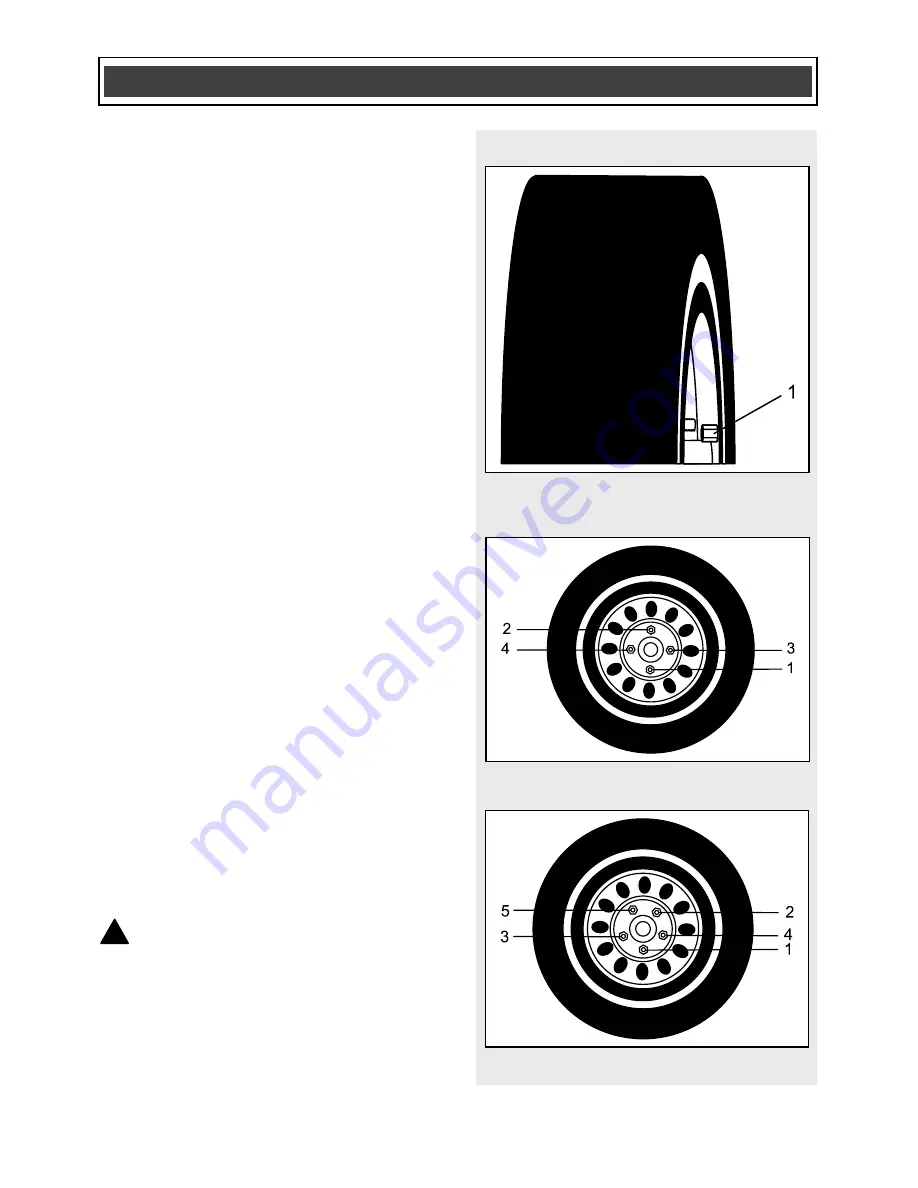

3. Place the wheel on the wheel studs

and thread one wheel nut (1)

clockwise onto each wheel stud

(Fig. 6).

NOTE:

Thread each wheel nut at least

three full turns onto the wheel stud to

make sure the nuts are NOT cross

threaded. The wheel stud and wheel nut

will be damaged if the nut is cross

threaded.

4. Grasp the impact wrench handle with

one hand and the front housing of the

impact wrench with the other hand.

5. Place the impact socket onto the

lower wheel nut (1) (Fig. 7 & 8).

NOTE:

Make sure the socket is fully

engaged with the nut to avoid potentially

damaging the socket or the wheel nut.

6. While holding the tool level with the

ground and with a firm grasp, squeeze

the

lower portion

of the trigger

switch. The impact wrench will tighten

the wheel nut to the set torque of 80

ft/lbs.

NOTE:

The LCD display will flash 3 times

and the impact wrench will stop when the

nut is tightened to 80 ft/lbs.

7. Proceed with tightening the remaining

wheel nuts to 80 ft/lbs as noted above.

WARNING:

Tighten the wheel nuts

in the sequence outlined in Fig. 7 for 4

stud wheel patterns and Fig. 8 for 5

stud wheel patterns.

Following this

sequence is extremely important to

avoid potential distortion of the brake

rotors or drums.

ASSEMBLY AND OPERATION

Fig. 6

Fig. 8

Fig. 7

!

ASSEMBLY AND OPERATION

Summary of Contents for 054-1265-6

Page 21: ...21 EXPLODED VIEW...