OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

27

26

11

1

11

model no. 055-6789-8 | contact us 1-800-689-9928

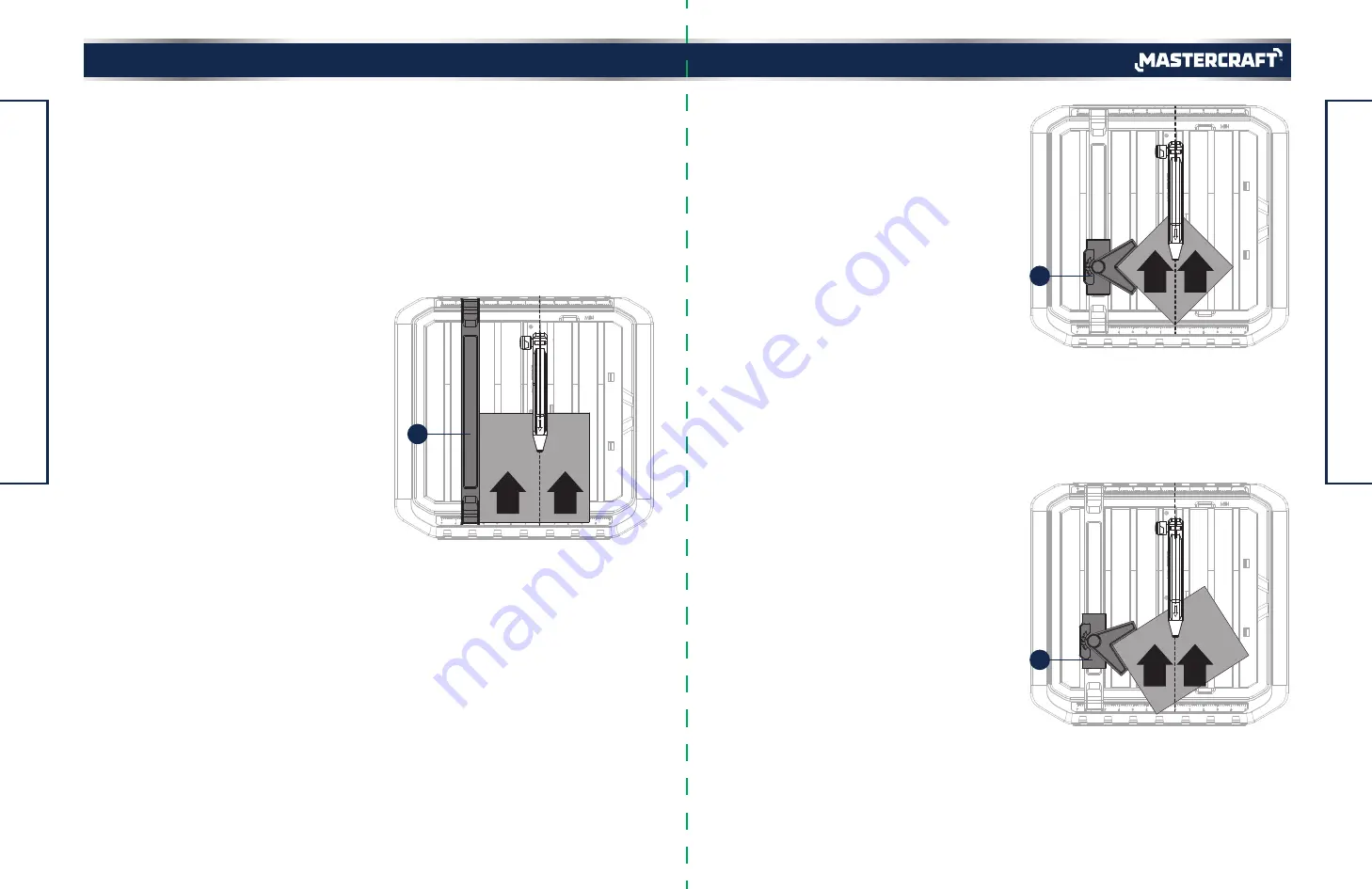

Fig. 14

Fig. 15

Fig. 16

MAKING A DIAGONAL CUT (Fig. 15)

45° Diagonal cuts are also referred to as “long point-to-

long point cuts”.

•

Using a marker or grease pencil, mark the area to be

cut on material.

• Install the mitre guide (11).

•

Adjust mitre guide to 45° using angle scale and tighten

securely with lock knob.

•

Place the material on the table and firmly against the

mitre guide.

•

Make sure the material is clear of the cutting wheel

before turning on the saw.

• Turn the on/off switch to the ON position.

•

Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

•

Hold the material firmly against the mitre guide and

table. Feed the material into the cutting wheel.

•

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before

removing any part of the material.

MAKING A MITRE CUT (Fig. 16)

Mitre cuts are used for cutting outside and inside corners

on material, decorative chair rails, and base mouldings

with the material at any angle to the wheel other than 90°.

Mitre cuts tend to “creep” during cutting. This can

be controlled by holding the workpiece securely against

the mitre guide.

•

Using a marker or grease pencil, mark the area to be

cut on material.

• Install the mitre guide (11).

•

Set the mitre guide to desired angle using the mitre

guide scale, and tighten securely with lock knob.

•

Place the material on the table and firmly against the

mitre guide.

•

Make sure the material is clear of the cutting wheel

before turning on the saw.

• Turn the on/off switch to the ON position.

•

Let the cutting wheel build up to full speed and wait for the wheel to get wet before moving the material into

the wheel.

• Hold the material firmly against the mitre guide and table. Feed the material into the cutting wheel.

•

When the cut is made, turn the saw OFF. Wait for the cutting wheel to come to a complete stop before removing

any part of the material.

•

ALWAYS draw the line to be cut on the tile using a marker or grease pencil. If the tile is shiny and hard-to-

mark, place masking tape on the tile and mark the tape.

•

A common problem when cutting tile is straying from the marked line. Once you’ve strayed from the mark,

you can not force the wheel back to the line by twisting the tile. Instead, back up and recut the tile slicing off

a small amount of tile until the wheel is back on track.

• To avoid this problem, use the rip guide or mitre guide whenever possible.

•

Another problem is cutting difficult material. To prevent chipping of the material at the end of the cut: first

cut 1 1/2" of the material, then turn off the saw; flip the material around 180° and make the cut.

•

Clean the saw blade, rip and mitre guides, and bevel table frequently during use. Debris from the cut material

can interfere with the function of the tool.

MAKING A CROSS CUT (Fig. 14)

Cross cuts are straight 90° cuts. The material is fed into

the saw at a 90° angle to the wheel.

•

Using a marker or grease pencil, mark the area to be cut

on material.

• Remove the mitre guide.

•

Position the rip guide (1) the desired distance from the

wheel for the cut and securely lock levers.

•

Place the material on the table, firmly against the rip

guide.

•

Make sure the material is clear of the cutting wheel

before turning on the saw.

• Turn the on/off switch to the ON position.

• Let the cutting wheel build up to full speed and wait for

the wheel to get wet before moving the material into the

wheel.

•

Hold the material firmly against the rip guide (1) and

feed the material into the cutting wheel.

When the cut is made, turn the saw OFF. Wait for the

cutting wheel to come to a complete stop before

removing any part of the material.