headline bars

continuation tabs

notes

warnings

17

headline bars

continuation tabs

notes

warnings

model no. 058-0051-2 | contact us 1-800-689-9928

16

PAR

TS LIST

TROUblESHOOTING

Problem

Possible Causes

likely Solutions

Will not spray.

1. Misuse of finger lever.

2. Needle chucking nut gets

loose.

3. Nozzle and/or air passage

blocked.

4. No air pressure at the air

brush.

5. Air pressure too low.

6. Material too heavy.

1. First press finger lever downward and then draw

back on the finger slowly/gently till fluid comes

out of the nozzle.

2. Make sure that the needle chucking nut is hand

tightened firmly around the fluid needle.

3. Clean.

4. Check air supply and air line.

5. Increase air pressure.

6. Thin material properly.

Grain spray.

Material too thick.

1. Add water or proper solvent sparingly to material.

2. Check needle and tip for dried material.

3. Adjust air supply; then test for proper spray.

Buckling paper.

Material too thin.

1. Add material to thicken mixture.

2. Airbrush less heavily in one area.

3. Move air brush rapidly or lessen amount of spray.

Spray pattern

appears to have

flared ends.

Turning wrist while spraying. Always move arm parallel to work surface to have

flared ends.

Spray pattern looks

like a centipede.

Spraying too much material

too close to paper.

1. Lightly pull back on finger lever.

2. Hold brush further away from work surface.

Splattering.

Allowing needle to snap back

into tip.

1. Release lever gently.

2. Check needle and tip for dried paint.

Curved spray

pattern.

Arcing arm too close to work

surface.

Always move arm parallel to work surface.

Spitting material.

1. Residue on needle or in

glass jar.

2. Material too thick.

1. Clean needle or glass jar with proper solvent or

clear water.

2. Thin material with proper solvent or clear water.

WARNING!

Follow all safety precautions whenever diagnosing or servicing the air brush. Disconnect air supply before service.

MAINTENANCE

STORING

1. When not using the air brush, it must be well cleaned and lightly lubricated.

2. Store the air brush in a dry and safe place out of reach of children.

17

18

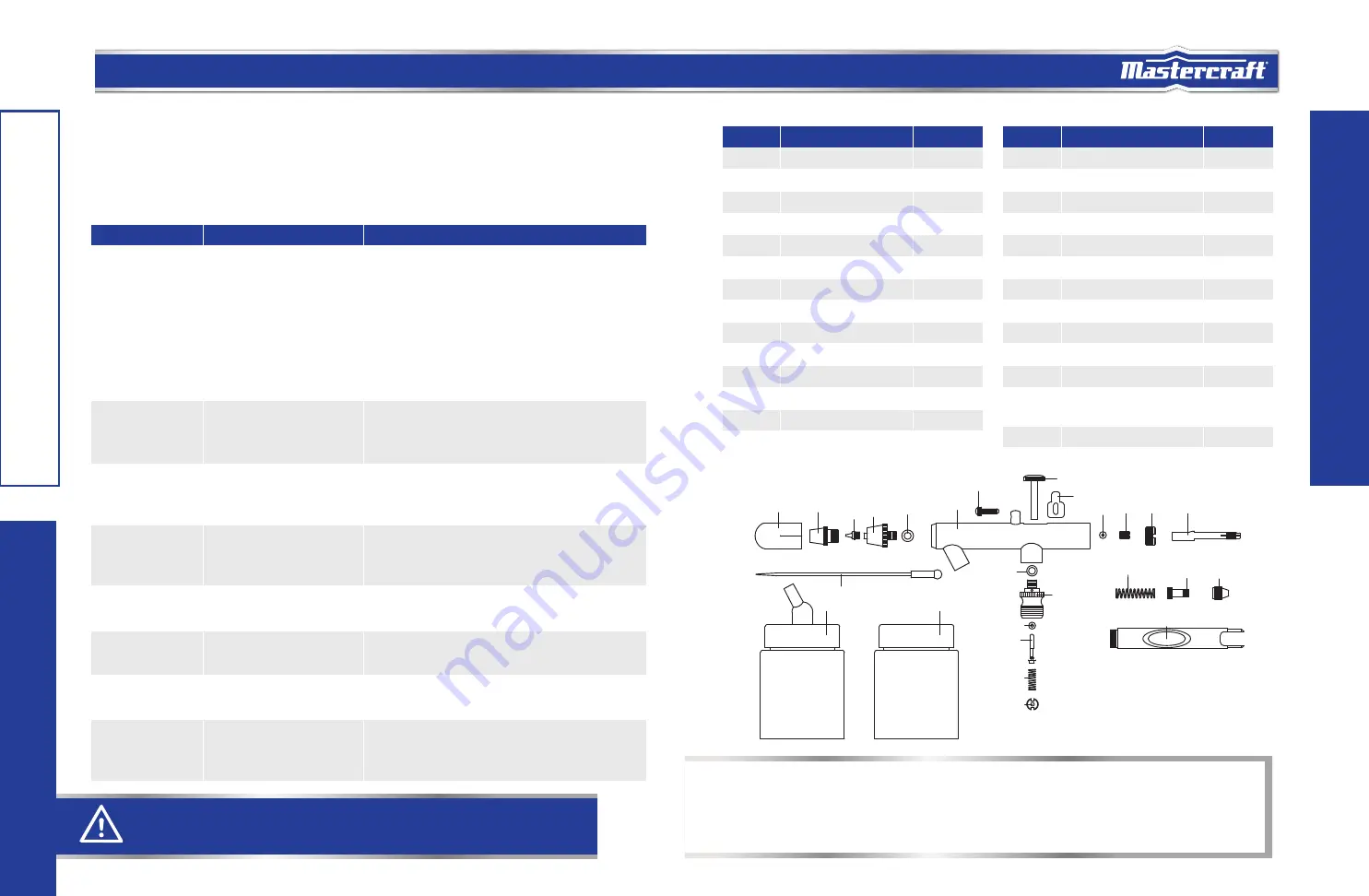

4

3

6

2

1

19

9

10

8

11

21

20

22

23

25

26

5

24

16

7

14

12

13

15

NOTE:

The manufacturer and/or distributor has provided the parts list and assembly diagram in this manual as a reference tool only. Neither the manufac-

turer nor distributor makes any representation or warranty of any kind to the buyer that he or she is qualified to make any repairs to the product, or

that he or she is qualified to replace any parts of the product. In fact, the manufacturer and/or distributor expressly states that all repairs and parts

replacements should be undertaken by certified and licensed technicians, and not by the buyer. The buyer assumes all risk and liability arising out of

his or her repairs to the original product or replacement parts thereto, or arising out of his or her installation of replacement parts thereto.

No.

Description

Qty.

1

Protective cap

1

2

Air cap

1

3

Nozzle

1

4

Air cap body

1

5

O-ring

1

6

Packing

1

7

Packing nut

1

8

Housing

1

9

Adjustment screw

1

10

Finger lever

1

11

Rocker

1

12

Stopper

1

13

Needle chucking guide

1

No.

Description

Qty.

14

Spring

1

15

Spring case

1

16

Needle chucking nut

1

17

Handle

1

18

Needle

1

19

O-ring

1

20

Valve rod

1

21

O-ring

1

22

Spring

1

23

Valve screw

1

24

Valve body

1

25

Glass jar with lid and

fluid connector (22 cc)

1

26

Glass jar with lid (22 cc)

1

TROUBLESHOO

TING