OPERA

TING INSTR

UCTIONS

16

AIR

-

POWERED PIN NAILER 058

-

8122

-6

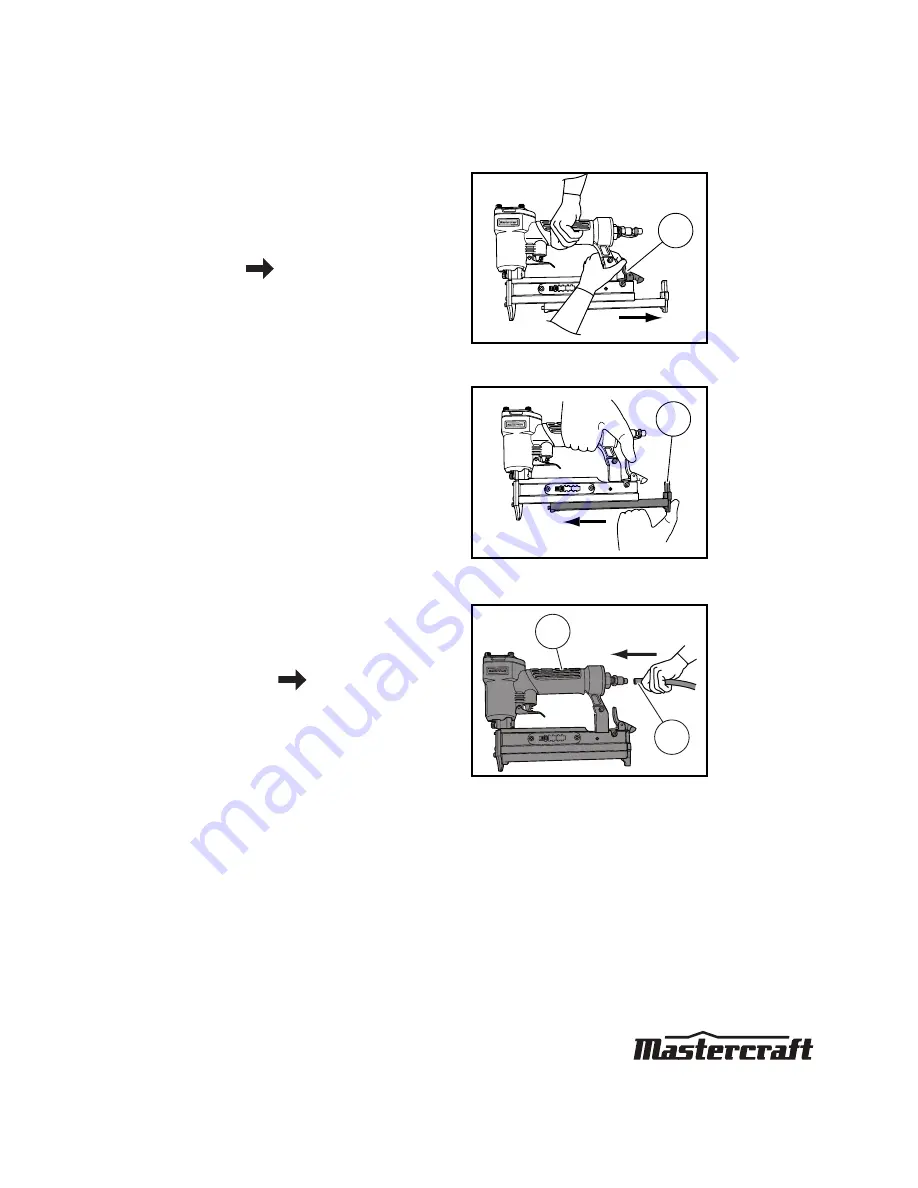

3. Take hold of the nailer firmly with one

hand and use the other hand to press

the magazine latch (1) and slide it back.

Insert a strip of nails into the magazine.

Ensure the points of the nails are facing

down

(fig C)

. (see nail type

icon on page 14)

4. Slide the pusher (1) against the nails to

close the magazine until it comes into

contact with the nails and locks into

place

(fig D)

.

5. Plug in compressor, turn it on, set the

pressure regulator to 90 psi, attach one

end of the air hose to the compressor

and the other end of the air hose (1) to

the tool (2)

(fig E)

. page 11

(wood density chart)

6. Use plumber’s tape to avoid air leak.

Verify that the air pressure is in the

correct range

(see section “Technical

specifications”)

. The tool is now ready

for use.

MC-588122-05

1

fig C

MC-588122-06

1

fig D

MC-588122-07

fig E

2

1

Summary of Contents for 058-8122-6

Page 1: ...INSTRUCTION MANUAL AIR POWERED PIN NAILER 058 8122 6...

Page 3: ......

Page 18: ......

Page 24: ...TROUBLESHOOTING 24 AIR POWERED PIN NAILER 058 8122 6...