17

16

model no. 058-9807-2 | contact us 1-800-689-9928

Adjustments

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

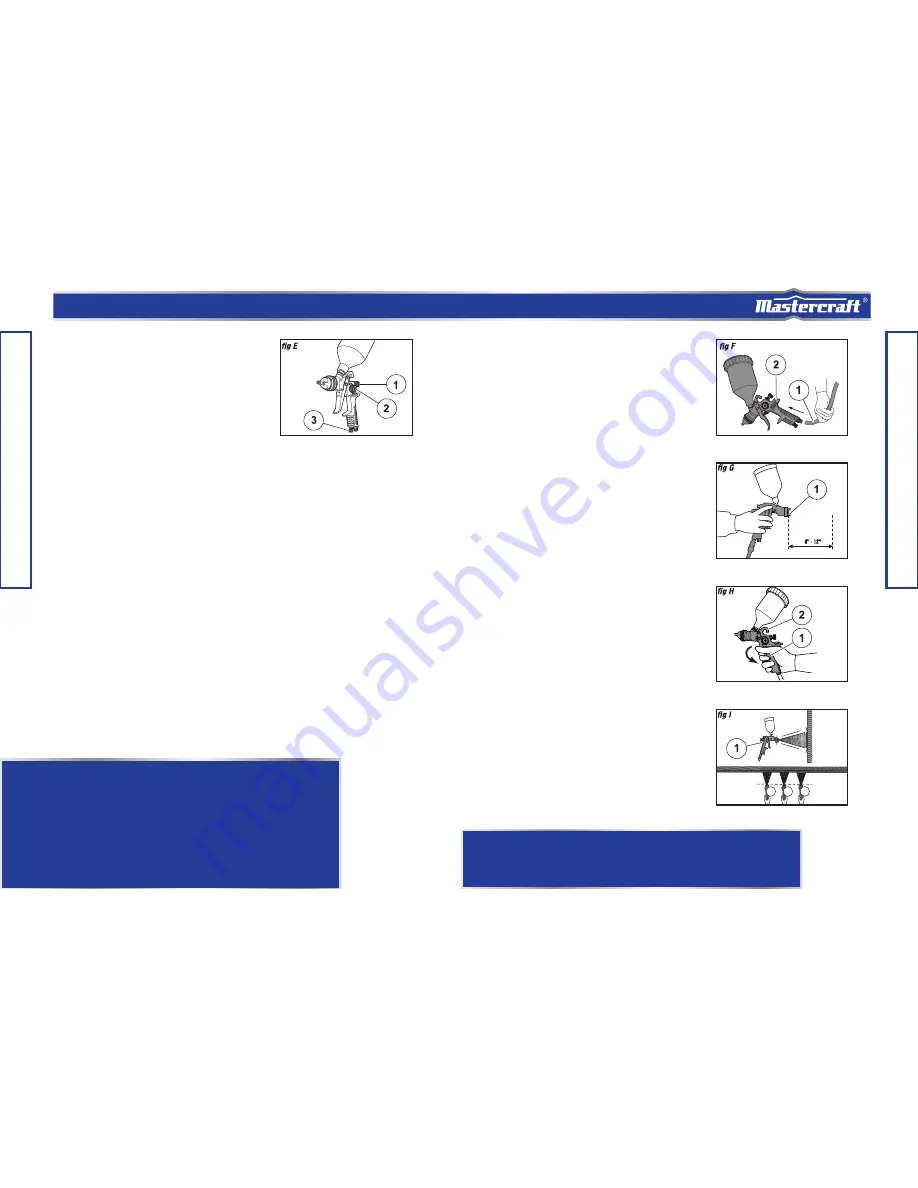

The Gravity-feed Spray Gun has a pattern

adjusting knob (1), a paint adjusting knob (2),

and an air adjusting knob (3) that are used to

obtain the desired pattern, to control the output

volume of paint, and to obtain fine atomization,

respectively (fig E).

PATTERN ADJUSTMENT

Rotate the pattern adjusting knob clockwise to

form a circular spray pattern and rotate the

knob counter-clockwise to form an elliptical

spray pattern.

PAINT ADJUSTMENT

Rotate the paint adjusting knob clockwise to

reduce the output volume of paint and rotate

the knob counter-clockwise to increase the

output volume of paint.

AIR VOLUME ADJUSTMENT

Rotate the air adjusting knob clockwise to

reduce the output volume of air and rotate the

knob counter-clockwise to increase the output

volume of air.

Operation

1. Plug in compressor, turn it on set the

pressure regulator to 40 PSI, attach one

end of the air hose to the compressor

and the other end of the air hose (1) to

the air tool (2) (fig F).

2. Hold the spray gun (1) so that the nozzle

is approximately 6 to 12” from the work

surface, perpendicular to the spraying

area (fig G).

Note:

Do some practice sprays while adjusting

the spray pattern and setting up the gun, using

a spare surface (scrap piece of metal).

3. Squeeze the trigger (1) of the spray gun

(2). Start moving the gun before pressing

the trigger and release the trigger before

stopping the gun movement at the end

of each stroke. This procedure will blend

each stroke with the next without any

overlap or unevenness (fig H).

4. Move the spray gun (1) at a constant

pace in a back and forth parallel

direction, maintaining a uniform distance

from the surface to be painted (fig I).

5. Repeat the strokes until a uniform

coating is formed.

Potential hazard that could result in serious injury or loss of life.

WARNING!

• Do not exceed the maximum pressure for the Air-powered Gravity-feed

Spray Gun or any other parts in the compressor system. Failure to comply

could lead to serious injury or loss of life.

• Never aim or spray at yourself or anybody else as this could cause serious

injury. Failure to comply could lead to serious injury or loss of life.

• After unpacking the tool, inspect it carefully and check thoroughly for

any damage that may have occurred during transit. Ensure the tightness

of fittings, bolts, etc., before performing service operation.

performed.

NOTE:

Use a piece of cardboard as a shield to capture

the loss of spray paint at the ends of the workpiece to

protect other surfaces from being painted.