19

18

NOTE:

The standard CONTACT TRIP MECHANISM and the optional SQUENTIAL

TRIP MECHANISM are safe if used as described above and according to

all warnings and instructions.

Always handle nails and container carefully. If nails are dropped, collating

wire may be damaged and cut, which will cause mis-feeding and jamming.

After nailing: disconnect air hose from the nailer, remove all nails from the

nailer, add 5-10 drops of pneumatic tool lubricant into the air plug in the

nailer and open the petcock on the air compressor tank to drain any

moisture.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

model no. 058-9809-8 | contact us 1-800-689-9928

The installed sequential fire (single shot) mechanism is useful for when precision nail placement

is desired. It may also reduce the possibility of bodily injury to you or others in the work area as

it is less likely to drive an unwanted nail by accidentally bumping the push lever while the trigger

is pulled. The bump fire (multiple shot) mechanism is useful when repetitive, fast firing is required.

model no. 058-9816-0 | contact us 1-800-689-9928

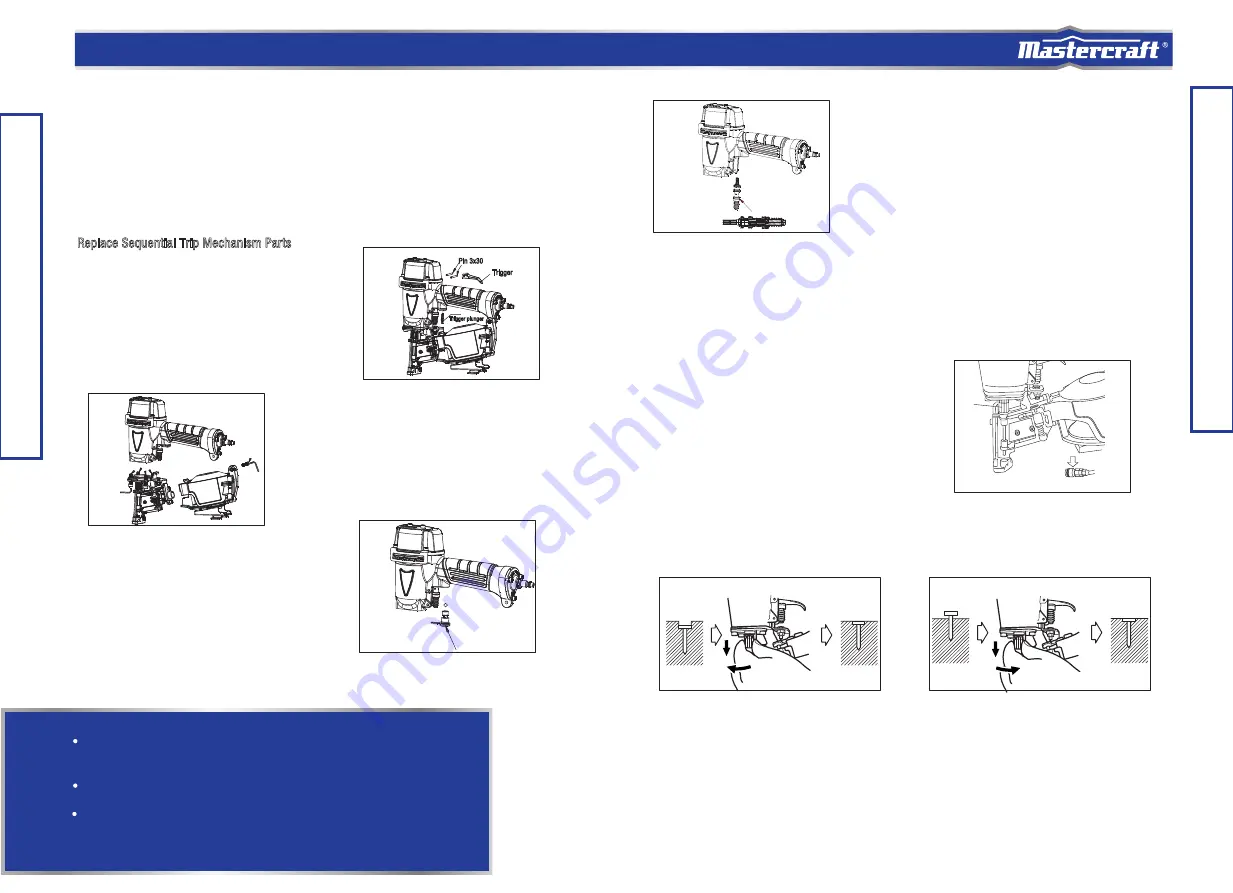

1. Insert a rod into the trigger hole, tapping the rod

with two pins and remove the trigger and the

trigger plunger (Fig. L).

Replace Sequential Trip Mechanism Parts

2. Use a M5 hex wrench to remove the screw as

shown, releasing the magazine and nail guide

assembly (Fig. M).

3. Remove the trigger valve bushing assembly

and the urethane ball (Fig. N).

Pin 3x30

Trigger

Trigger plunger

Fig. L

Ball

Fig. N

Fig. M

4. Remove the contact trip valve seat components

(including plunger and plunger spring), and then

changed into sequential trip valve seat components

and grease the o-rings (Fig. O).

5. Reassemble by comleting step 1 to 3 in reverse order.

Fig. O

Fig. P

Fig. Q

Fig. R

Part#111

Adjusting the nailing depth

h

s

u

l

F

p

e

e

d

o

o

T

Turn adjuster

2

Turn adjuster

Too shallow

Flush

2

To assure that each nail penetrates to the same depth, be sure that:

①

The air pressure to the nailer remains constant (regulator is installed and working properly).

②

The nailer is always held firmly against the workpiece. If nails are driven too deep or too shallow into the

workpiece, adjust the nailing depth using the following instructions.

1

.

Disconnect air hose from nailer (Fig. P).

2a. If the nails are driven too deep, pull the adjuster

downward and turn counter-clockwise (Fig. Q).

Adjuster

Disconnect air hose

2b. If nails are driven too shallow, pull the adjuster

downward and turn clockwise (Fig. R).

When the adjuster is released it will spring back up and can be set with a click at each 1/4 rotation. The

adjuster changes the nailing depth approximately 0.25 mm per 1/4 rotation.

3. Connect the air hose and perform a nailing test. ALWAYS WEAR EYE PROTECTION.

4. If additional adjustments are necessary, DISCONNECT AIR HOSE FROM NAILER and repeat step 2.