14

15

model no. 199-5705-2 | contact us 1-800-689-9928

OPER

A

CAUTION!

Verify that the metal bars in the water tray are covered with water. The water pump may be

damaged if it is not completely submerged while the tile saw is in use.

OPERATING INSTRUCTIONS

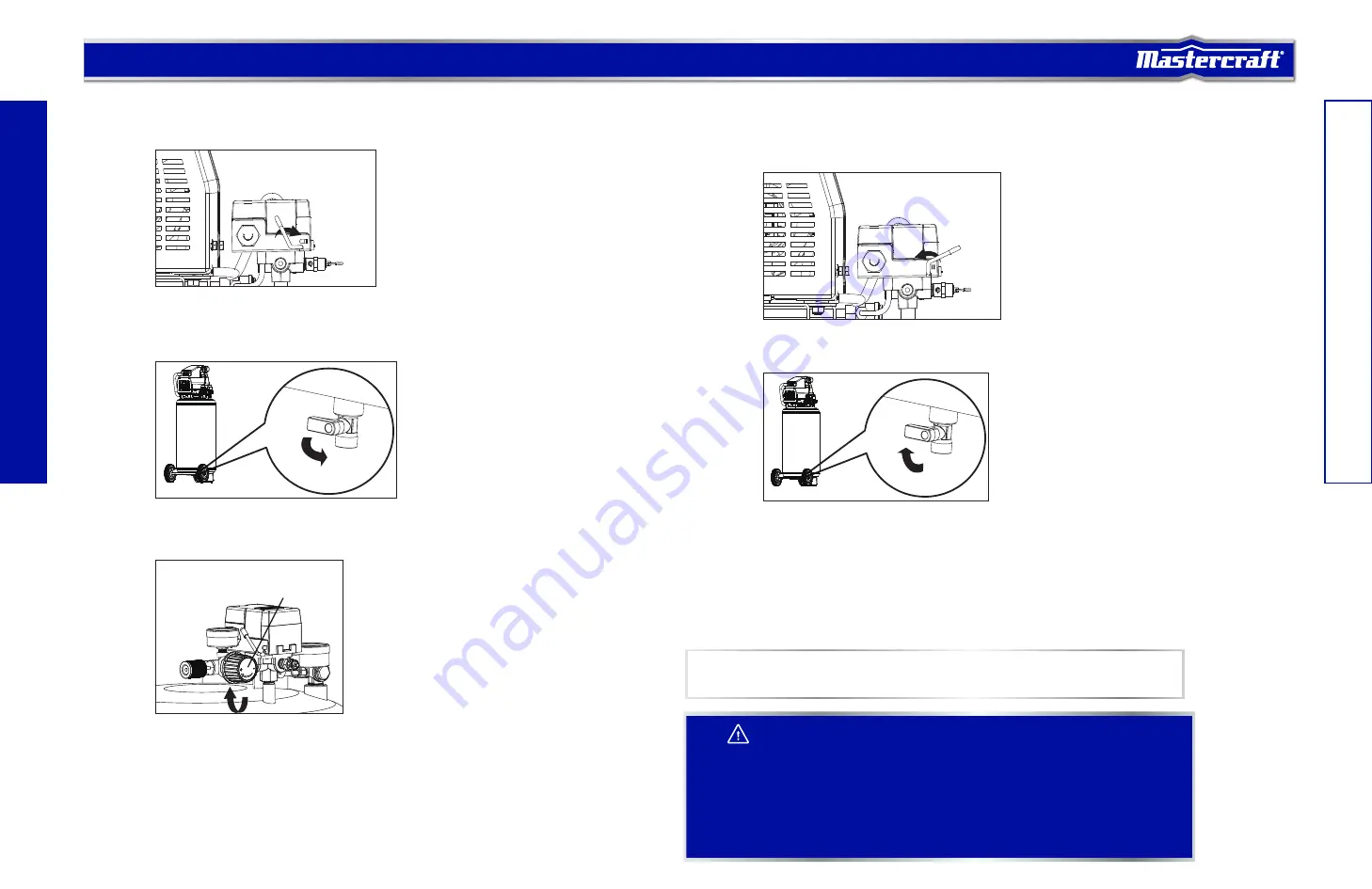

Breaking-in the pump

1.

Set the pressure switch (C) to the OFF position.

2.

Open the tank drain valve (I) by turning it counter-clockwise to permit the air to escape and

prevent air pressure build-up in the air tank during the break-in period.

3.

Turn the air pressure regulator (E) clockwise until it stops.

4.

Plug in the power cord (K).

NOTE:

A circuit breaker is recommended. If the air compressor is connected to a circuit protected by a

dual-element time delay fuses (type “T” only).

5.

Set the pressure switch (C) to the ON position. The compressor will start. Run the compressor for 30

minutes. If it fails, turn it off immediately and call the toll-free helpline at: 1-800-689-9928. Please note

that breaking-in the unit is only required prior to first use.

6.

After 30 minutes, turn off the pressure switch (C).

7.

Close the tank drain valve (I) by turning it clockwise.

8.

Set the pressure switch (C) to the ON position

.

The air receiver will fill to “cut-out” pressure and then

the compressor’s motor will stop. The compressor is now ready for use.

CAUTION!

Use a dedicated circuit.

For best performance and reliable starting, the air compressor should be plugged into a dedicated circuit,

as close as

possible to the fuse box or circuit breaker.

The compressor will use the full capacity of a typical 12

A household circuit. If any other electrical

from the compressor’s circuit, the air compressor may fail to start. Low voltage

sluggish starting that causes the motor overload protection

devices are drawing

or an overloaded circuit can result in

system or circuit breaker to trip, especially in cold conditions.

fuse, use

OPERATING INSTRUCTIONS

OFF

ON

open

CLOSE

OPEN